Why Your Choice of Ball Valve Supply Partner Defines Project Success

For procurement managers and design engineers, specifying components is more than a transaction—it’s a critical decision that impacts project timelines, budgets, and long-term operational reliability. This is especially true for fundamental components like ball valves. While many suppliers offer a ball valve purchase, only a reliable partner provides a true ball valve supply solution. Choosing based solely on price can be a costly mistake. Here are the five key benefits of partnering with a trusted ball valve supplier for your next project.

1. Absolute Quality Assurance and Certification

The most significant benefit of a reputable supplier is unwavering quality control. Inferior valves are a liability, risking leaks, failures, and dangerous downtime.

* Standards and Certifications: Top-tier ball valve suppliers provide products that meet or exceed international standards such as API 6D, ANSI/ASME B16.34, and ISO 9001. This ensures materials, manufacturing processes, and testing protocols are rigorously validated.

* Impact on Project Longevity: A quality flanged ball valve supplier doesn’t just sell you a product; they sell you peace of mind. Valves built to spec withstand pressure, temperature, and corrosive media, directly extending the lifecycle of your entire system and reducing total cost of ownership.

2. Diverse and Specialized Product Range

No two projects are identical. A reliable supplier offers a vast inventory to meet exact specifications, preventing costly design compromises.

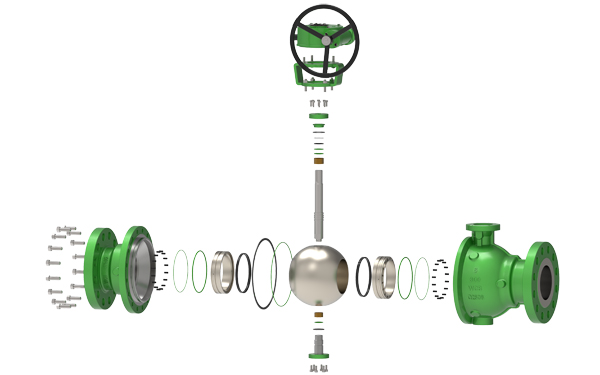

* Types of Ball Valves: A true partner stocks everything from standard floating ball valves to high-performance trunnion mounted ball valves. Whether you need a compact pneumatic ball valve supplier for automation or a ball valve for water supply applications, they have you covered.

* Specialized Applications: The best suppliers offer valves in various materials (brass, stainless steel, alloy), end connections (threaded, flanged, socket weld), and for specific industries (oil & gas, chemical processing, water treatment). This eliminates the need to manage multiple vendors.

3. On-time Delivery and Supply Chain Reliability

In today’s global landscape, a consistent and predictable supply chain is invaluable. Delays in receiving valves can halt multi-million dollar projects.

* Reducing Downtime: A dependable ball valve supply partner has robust logistics and inventory management systems to ensure your orders arrive exactly when needed, keeping your project on schedule.

* Scheduling Considerations: They provide accurate lead times and proactive communication about potential disruptions. This allows you to plan effectively, mitigating risks associated with just-in-time manufacturing and tight construction timelines.

“NSW Valve maintains 3 regional warehouses (North America, Europe, Asia) to ensure 98% of orders are delivered within 5 business days—2x faster than industry average.”

4. Competitive Pricing and Total Cost Value

While initial cost is a factor, the lowest price often leads to the highest long-term expenses. Reliable suppliers focus on value.

* Cost-Benefit Analysis: A cheaper valve may require frequent replacement, cause system failure, or demand more maintenance labor. A quality valve from a trusted valve ball supplier offers a better return on investment through unparalleled durability and performance.

* Supplier Comparison: Established suppliers often have efficient global sourcing (e.g., as a leading China ball valve supplier, NSW Valve combines cost-effective manufacturing with stringent quality control) and economies of scale, allowing them to offer competitive prices without sacrificing quality.

5. Enhanced Technical and Customer Support

This is what truly separates a supplier from a partner. They act as an extension of your team.

* Expert Consultations: Knowledgeable support staff can help you select the right valve for your application, pressure rating, and media. They provide critical technical data, CAD drawings, and specification sheets to streamline your design process.

* After-Sales Services: A premier ball valves supplier stands behind their products with comprehensive warranty support, readily available spare parts, and troubleshooting assistance. This long-term support is crucial for maintaining operations years after the initial ball valve purchase.

“For a recent oil & gas client in Texas, our engineers adjusted the valve’s seal material to withstand 300°F high temperatures—solving their 6-month-long leakage issue and saving $200k in maintenance costs.”

Conclusion: Partner for Success

Choosing a ball valve supply partner is a strategic decision. The benefits extend far beyond the transaction, impacting your project’s integrity, schedule, budget, and long-term operational success.

By prioritizing a supplier that offers quality assurance, a diverse range, timely delivery, competitive value, and expert support, you mitigate risk and build a foundation for project excellence.

Ready to experience the difference a reliable partner makes? Explore NSW Valve’s extensive catalog as your trusted ball valve supplier. Contact our experts today for a quote or technical consultation to ensure your next project is built on a foundation of reliability.

Common Questions About Ball Valve Supply

How to verify if a supplier’s API 6D certification is valid?

Check the API Portal and ask for the supplier’s certification number—verifiable online.

What if my project needs a custom ball valve?

NSW Valve offers 2-week fast customization for most specifications, with free sample testing before mass production.

Post time: Sep-18-2025