In many industrial facilities across the United States, the pneumatic actuator valve remains one of the most dependable solutions for automated flow control. Fast response, straightforward mechanical construction, and inherent safety in hazardous environments make pneumatic valves and actuators a practical choice for system designers, maintenance teams, and procurement specialists.

This guide provides a detailed, technically grounded overview of how pneumatic actuator valves work, what differentiates various actuator types, and which selection criteria matter most in real applications.

Understanding Pneumatic Actuator Valves

Definition and Function

A Pneumatic Actuator Valve combines a valve body with an air-driven actuator that opens, closes, or modulates flow. Unlike electric actuators, pneumatic systems react quickly, tolerate harsh ambient conditions, and operate safely in combustible atmospheres.

Industries such as chemical processing, food and beverage, pulp and paper, water treatment, and energy generation rely heavily on pneumatic control because these systems:

- Produce no ignition source

- Deliver rapid actuation and reliable cycle life

- Are easy to maintain and cost-effective over long service periods

- Support “fail-safe” operation during power or air loss

These advantages explain why pneumatic control valves remain a standard in U.S. industrial automation.

How Pneumatic Actuator Valves Work

A typical pneumatic actuator valve assembly includes:

- The valve (ball, butterfly, globe, gate, diaphragm, etc.)

- A pneumatic actuator

- An optional positioner for precise control

- Solenoid valves for directional switching

- Air filtration and regulation components

- Limit switches or feedback sensors

Basic Operating Sequence

- A control system (PLC/DCS) sends a signal—4–20 mA, HART, or pneumatic.

- The positioner converts that signal into the correct air pressure.

- Air pressure moves a piston or diaphragm.

- The actuator transfers this motion to the valve stem or shaft.

- The valve adjusts according to the required setpoint.

For pneumatic modulating service, the performance of the positioner is as important as the actuator itself. For on/off applications, torque margin and mechanical reliability matter most.

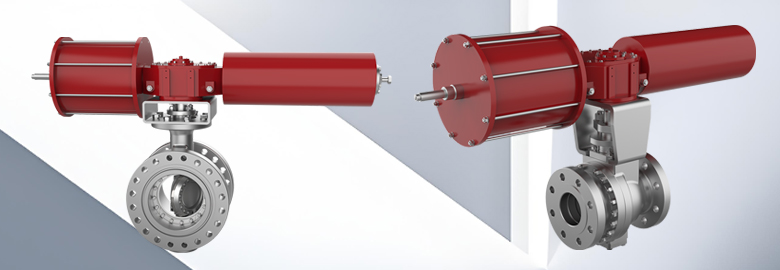

Types of Pneumatic Valve Actuators

Standard Pneumatic Valve Actuators

Spring-Return (Single-Acting) Actuators

A spring forces the valve to a predetermined fail position (open or closed) if air pressure is lost. These actuators suit safety-critical applications such as burner management, cooling systems, fuel isolation, or ESD valves.

Why they’re used:

- Defined fail-safe direction

- Lower air consumption

- Ideal for shutdown logic

Double-Acting Actuators

Air pressure drives both opening and closing strokes, providing consistent torque throughout the cycle.

Best for:

- High-cycle operations

- Larger valves

- Fast actuation requirements

- Modulating duty

Rotary Pneumatic Actuators

Used with ball valves, butterfly valves, and other quarter-turn designs.

Two main mechanisms:

- Rack and pinion: compact and economical

- Scotch yoke: produces higher break torque and handles heavy-duty applications better

Linear Pneumatic Actuators

Designed for globe valves, diaphragm valves, and other linear-stroke valves.

Types include:

- Diaphragm actuators: sensitive control, low pressure

- Piston actuators: longer travel, higher thrust

Specialty Pneumatic Actuators

Some applications require more specialized equipment:

High-Cycle Actuators

Built for operations exceeding hundreds of thousands—or even millions—of cycles. Reinforced bearings and advanced lubrication paths reduce wear.

High-Torque or Heavy-Duty Actuators

Used for large-diameter valves or viscous media. Often based on scotch-yoke mechanisms due to their torque characteristics.

Extreme Environment Actuators

For cryogenic services, high temperatures, or corrosive environments.

Common upgrades include:

- Stainless steel housings

- Epoxy or marine-grade coatings

- Low-temperature elastomers

Key Features to Consider

1. Valve Compatibility

One of the most common causes of startup issues is a mismatch between the valve and the actuator.

Key items to confirm:

- Rotary or linear motion requirement

- ISO 5211 mounting pattern and stem dimensions

- Full torque profile (break, running, and seating torque)

- Media characteristics: viscosity, solids, temperature

- Required shutoff class or sealing performance

Engineers typically aim for 25–30% torque margin, and in abrasive or high-build-up services, a margin closer to 40–50% is advisable.

2. Actuation Speed and Torque

Torque Requirements

Torque must account for:

- Differential pressure

- Valve sealing friction

- Process temperature

- Potential buildup on internal surfaces

Choosing an undersized actuator can lead to sticking, incomplete stroke, or premature wear.

Actuation Speed

Typical ranges:

- Emergency shutdown: < 1 second

- Process interlocks: 1–3 seconds

- Modulating valves: slower, controlled response preferred

Speed can be adjusted via solenoid selection, air line sizing, or flow controls in the pneumatic circuit.

3. Operating Pressure Range

Most facilities in the U.S. run plant air between 80–120 PSI, but performance depends partly on air quality.

Essential conditioning steps:

- Particulate filtration

- Pressure regulation

- Moisture removal (refrigerated or desiccant dryers)

- Regular drainage of receivers and filters

Positioners and modulating valves are particularly sensitive to contaminants.

Installation and Maintenance

Installation Best Practices

- Ensure actuator and valve are properly aligned.

- Adjust travel stops carefully to avoid damaging valve seats.

- Install solenoids and accessories according to NAMUR standards where applicable.

- Confirm fail-open or fail-closed orientation before commissioning.

- Tighten air connections and check for leaks after pressurization.

For high-cycle or safety-critical valves, adding position feedback is highly recommended.

Routine Maintenance Tips

Maintenance usually focuses on wear points:

- Inspect seals and O-rings every 6–12 months.

- Empty filter bowls and drain condensate frequently.

- Check bearings and linkage for looseness.

- Run diagnostics or partial-stroke tests on smart positioners.

- Verify zero and span calibration annually.

Predictive maintenance becomes significantly easier when actuators are paired with digital positioners that log cycle counts and performance trends.

Common Issues and Troubleshooting

Typical issues and practical checks:

- Slow movement – clogged filters, inadequate supply pressure, or undersized air lines.

- Incomplete closure – incorrect travel stops or damaged valve seats.

- Oscillation in modulating service – positioner tuning or air supply instability.

- Air leaks – fittings, body seals, or actuator end caps.

- Unusual noise – bearing wear or misalignment.

Addressing these issues early prevents unplanned downtime and extends actuator life.

Conclusion

Summary of Key Points

Selecting the right pneumatic actuator valve depends on understanding the valve’s torque profile, environmental conditions, fail-safe requirements, and air supply quality. Matching actuator characteristics to the valve and process environment is essential for long-term reliability.

Final Recommendations

- Verify all torque data with the valve manufacturer.

- Choose actuators with proven cycle life and corrosion-resistant construction.

- For regulating applications, always pair the actuator with a high-quality positioner.

- Keep detailed records of installation, calibration, and maintenance activities.

When properly selected and maintained, a pneumatic actuated valve can operate dependably for years while keeping maintenance costs low and system performance high.

Post time: Dec-10-2025