What Is a Pneumatic Valve?

Definition of a Pneumatic Valve

A Pneumatic Valve is a type of industrial control valve driven by compressed air. By converting air pressure into mechanical motion, the actuator opens, closes, or adjusts the valve to control the flow of liquids, gases, steam, or corrosive media.

Common designs include pneumatic ball valves, butterfly valves, gate valves, and fast-acting shut-off valves.

Working Principle of Pneumatic Valves

Compressed air enters the actuator chamber, pushing a piston or diaphragm. This motion drives the stem to rotate or move linearly, causing the valve to open or close. In automated systems, the actuator is controlled by PLC or DCS signals for precise flow management.

Typical Media

-

Air and inert gases

-

Process water and industrial liquids

-

Steam systems

-

High-temperature, corrosive, or hazardous chemicals

Functions and Advantages of Pneumatic Valves

Main Functions

Automated On/Off Control

Pneumatic valves enable reliable remote operation in industrial pipelines, eliminating the need for manual intervention.

Accurate Modulating Control

When fitted with a positioner, the valve can deliver stable and repeatable control of flow, pressure, or temperature.

Key Advantages

Fast Response Time (Often < 1 Second)

Ideal for emergency shutdown and protective systems.

High Safety With Natural Explosion-Proof Properties

Because the actuator uses air instead of electricity, it can be safely applied in hazardous zones.

Long Service Life and Low Maintenance

The mechanism is simple, with fewer parts susceptible to failure.

Suitable for Large-Diameter and High-Pressure Pipelines

Pneumatic ball and butterfly valves perform especially well in these demanding applications.

Main Components of Pneumatic Valves

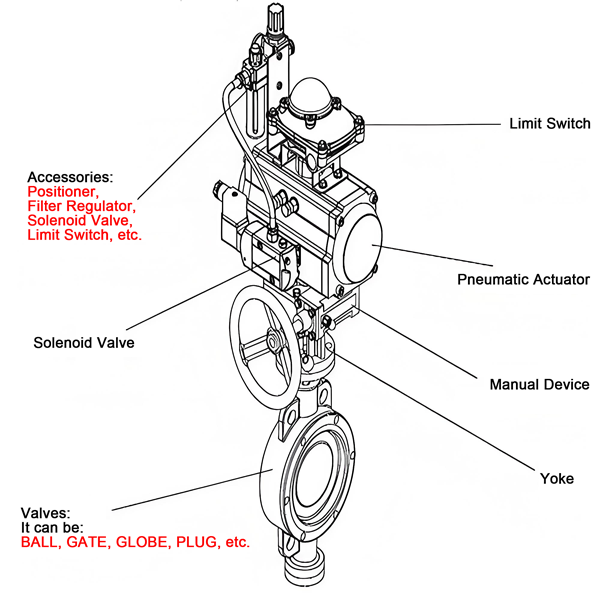

Pneumatic Actuator

Single-Acting Actuator (Spring Return)

Uses a spring to return to a safe fail-close or fail-open position during air loss.

Double-Acting Actuator

Air is supplied to both sides of the piston, providing greater torque and smoother operation.

Valve Body Types

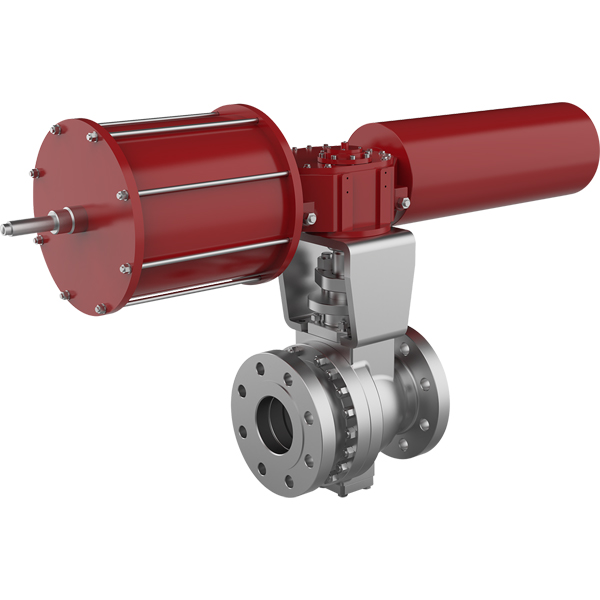

Pneumatic Ball Valve

Offers tight sealing and low leakage, commonly used for gas isolation.

Pneumatic Butterfly Valve

Lightweight and cost-effective; widely used in water treatment and large pipeline systems.

Pneumatic Gate Valve

Minimizes pressure drop; preferred for slurry, powder, or solid-laden fluids.

Pneumatic Globe / Control Valve

Designed for accurate flow modulation.

Control Accessories

-

Solenoid valve

-

Limit switch box

-

Air filter regulator (FRL)

-

Positioner for modulating control

Main Types of Pneumatic Valves

By Valve Structure

-

Pneumatic ball valves

-

Pneumatic butterfly valves

-

Pneumatic gate valves

-

Pneumatic shut-off valves

-

Pneumatic control valves

By Actuator Type

-

Single-acting

-

Double-acting

By Function

-

On/off valves

-

Modulating control valves

Comparison Between Pneumatic Valves and Manual Valves

Operation

Pneumatic valves provide automated and remote operation, whereas manual valves require physical handling.

Performance

Pneumatic valves can switch frequently and react quickly; manual valves are slower and less suitable for automated cycles.

Application

Pneumatic valves fit automated production lines; manual valves are typically used in simpler, low-frequency operations.

Comparison Between Pneumatic Valves and Electric Valves

Power Source

-

Pneumatic: compressed air

-

Electric: motor drive

Speed

Pneumatic valves generally offer faster actuation.

Safety

Because no motors or sparks are involved, pneumatic valves are suitable for explosive environments.

Maintenance

Air-driven actuators have fewer moving parts and lower overall maintenance requirements.

Application Fields of Pneumatic Valves

Oil and Petrochemical

Used in gas transmission, tank farms, cracking units, and emergency shutdown systems.

Water Treatment

Pneumatic butterfly valves are common in municipal distribution and wastewater plants.

Food & Pharmaceuticals

Sanitary pneumatic valves support beverage processing and CIP systems.

Natural Gas, Steam & Energy Industry

Pneumatic ball and shut-off valves provide reliable isolation for steam and gas.

Machinery, Metallurgy & Pulp Industry

Used in air supply systems, slurry pipelines, and process control.

Maintenance of Pneumatic Valves

Daily Inspection

-

Verify correct air pressure (typically 0.4–0.7 MPa)

-

Check for air leakage

-

Confirm position feedback

Actuator Maintenance

-

Replace worn seals

-

Inspect spring force

-

Lubricate internal moving surfaces

Valve Body Maintenance

-

Clean internal surfaces

-

Replace sealing rings

-

Lubricate the stem

Accessory Maintenance

-

Clean solenoid valves

-

Drain filter regulators

-

Calibrate positioners

Pneumatic Valve Selection Guide

Key Considerations

-

Type of medium

-

Pressure and temperature conditions

-

Required Cv/Kv value

-

Valve size (DN15–DN1500)

-

Explosion-proof or safety requirements

-

Actuation speed and fail-safe design

-

Environmental and installation conditions

Industry Standards

Common International Standards

-

ISO 5211 (Actuator mounting interface)

-

API 6D / API 608 (Ball valve standards)

-

GB/T 12237 (Industrial valves)

-

GB/T 9113 (Flange specification)

FAQ About Pneumatic Valves

1. Is a pneumatic ball valve better than a pneumatic butterfly valve?

Ball valves provide superior sealing, while butterfly valves are more economical for large pipelines.

2. How long does a pneumatic actuator last?

Typically between 300,000 and 1,000,000 cycles, depending on air quality and operating conditions.

3. Do pneumatic valves need lubrication?

Most actuators are self-lubricating, but some mechanisms may require periodic greasing.

4. When should a pneumatic shut-off valve be used?

In emergency shutdown (ESD), hazardous media isolation, or rapid-response safety applications.

5. What’s the difference between single-acting and double-acting actuators?

Single-acting provides a fail-safe action; double-acting offers higher torque and more stable control.

Post time: Dec-06-2025