Selecting valves for industrial liquid systems involves balancing durability, pressure capability, long-term reliability, and cost. In many facilities—from power generation to petrochemical plants—carbon steel ball valves have become a dependable option due to their mechanical strength and suitability for demanding operating conditions. This article explains why carbon steel remains a practical material choice and how to select the right valve for your application.

What Is a Carbon Steel Ball Valve?

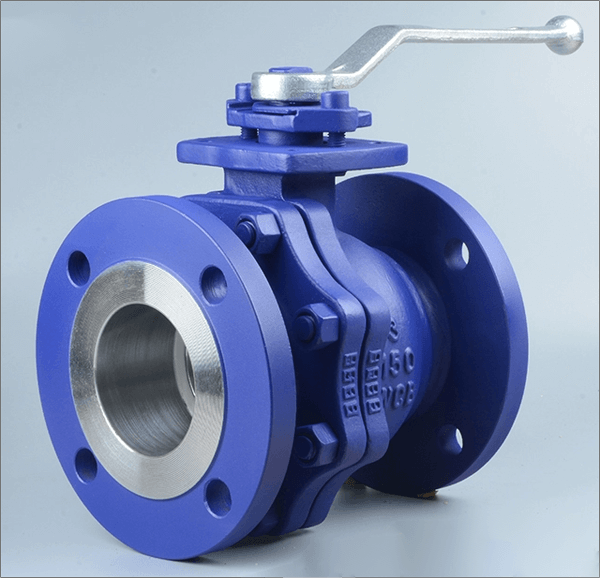

A carbon steel ball valve is a quarter-turn valve that uses a rotating ball with a through-hole to start or stop flow. Carbon steel provides the valve body with high tensile strength and the ability to withstand elevated pressures and temperatures, making it suitable for general industrial service as well as more challenging operating environments.

Key Advantages of Carbon Steel Ball Valves

1. Cost Efficiency With Reliable Performance

Carbon steel offers a strong combination of performance and affordability. Compared with stainless or specialty alloys, it provides adequate corrosion resistance for many industrial fluids while significantly reducing material costs—especially beneficial for systems requiring large quantities of valves or larger diameters.

2. Stable Flow Characteristics

Most carbon steel ball valves are designed with full-port or reduced-port configurations that minimize flow restriction. This helps maintain consistent system pressure and reduces pumping energy, supporting more efficient plant operation over time.

3. Compatibility With Common Industrial Media

When paired with appropriate seat and seal materials, carbon steel performs well in applications involving:

- Oils and hydrocarbons

- Cooling water

- Steam (within rated limits)

- Non-corrosive chemical solutions

Its versatility makes it a practical choice for many process pipelines and utility systems.

4. Strength for High Pressure and High Temperature Applications

Carbon steel grades such as ASTM A105 (forged) and A216 WCB (cast) are widely used for high-pressure and high-temperature service. These materials support pressure classes including Class 150, 300, 600, and higher, depending on design.

5. Long Service Life in Industrial Operation

Carbon steel’s mechanical strength helps resist fatigue, vibration, and water-hammer forces. With proper coating and periodic maintenance, these valves can offer long service life even in demanding industrial settings.

Comparison With Other Valve Materials

| Material | Advantages | Best Use Cases | Cost Level |

|---|---|---|---|

| Carbon Steel | Strong, suitable for high pressure/temperature, cost-effective | Utilities, general industrial service, oil & gas | Economical |

| Stainless Steel | Strong corrosion resistance | Corrosive chemicals, food & pharma | Higher |

| Duplex Steel | Excellent corrosion and strength properties | Offshore and chloride-rich environments | Premium |

| C95800 (Nickel Aluminum Bronze) | Excellent seawater resistance | Marine systems, seawater cooling | Specialty |

Typical Applications of Carbon Steel Ball Valves

Industrial Processing

Used for hydrocarbon handling, cooling water lines, condensate, and general utility piping in refining, energy, and manufacturing plants.

Power Generation

Ideal for feedwater systems, auxiliary cooling loops, and balance-of-plant services.

General Utility Networks

Applicable for plant water distribution, fire protection systems, and compressed air lines.

Automated Systems

Carbon steel ball valves can be combined with pneumatic, hydraulic, or electric actuators for remote or automated control.

How to Select the Right Carbon Steel Ball Valve

Step 1: Identify Operating Conditions

Key data to confirm before selecting a valve:

- Fluid type and characteristics

- Temperature range

- Maximum system pressure

- Required end connection (flanged, threaded, welded)

Step 2: Match Valve Specifications

Important considerations include:

- Valve size (e.g., common option: 2-inch ball valve)

- Floating or trunnion-mounted ball design

- Pressure class according to ASME/ANSI B16.34

- Seat and seal material suitable for the fluid and temperature

Step 3: Evaluate Manufacturer Quality

A qualified carbon steel ball valve manufacturer should provide:

- Compliance with API 6D, API 607 (if fire-safe), and ISO standards

- Material test certificates for body and trim components

- Pressure and seat tests for each valve

- Technical support and documentation

Choosing a reputable supplier ensures that the valve performs reliably throughout its service life.

Conclusion

Carbon steel ball valves combine strength, durability, and cost efficiency, making them suitable for a wide range of industrial liquid control applications. When selected according to system requirements and sourced from a reliable manufacturer, they provide stable performance in both standard and high-pressure operations. For facilities looking for a practical and dependable solution, carbon steel remains a proven choice.

FAQs

Can carbon steel ball valves be used for steam?

Yes. Many carbon steel valves are rated for steam service, but the pressure-temperature rating and seat material must match the application.

Do carbon steel valves need external coating?

In outdoor or humid environments, protective coatings are recommended to reduce atmospheric corrosion.

What information is needed when specifying a valve?

Key details include size, pressure class, end connections, fluid properties, operating temperature, and preferred actuation method.

Post time: Dec-08-2025