Double Eccentric Butterfly Valves

What is Double Eccentric Butterfly Valve

Double eccentric butterfly valve is an industrial valve with double eccentric structure design. It can quickly disengage from the sealing surface through the valve shaft structure with two offsets, and has both fluid regulation and cutoff functions. Its core features are high pressure resistance, low wear, long life and high sealing performance. It is widely used in many fields such as urban water supply and drainage, metallurgy, and chemical industry.

Detail of Double Eccentric Butterfly Valves

Valves Information

Size: NPS 1-1/2 Inch to NPS 80 Inch (DN40 to DN2000)

Pressure Range: Class 150lb, Class 300, Class 600.

End Connection: Wafer, Flange, Lug.

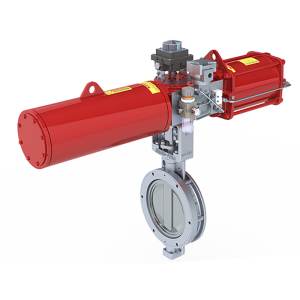

Actuator: Lever, Gear Box, Pneumatic Actuator, Electric Actuator, Hydraulic Actuator

Material: Ductile Iron, WCB, Stainless Steel, Duplex Stainless Stee, CF8, CF8M, CF3, CF3M, C95800, 4A, 5A, etc.

Standards

| Design and Manufacturer | API 609 |

| Face to Face | ASME B16.34 |

| End Flange | ASME B16.5, ASME B16.47 |

| Test and Inspection | API 598 |

Definition and structural characteristics

Double eccentric design:

The valve shaft center deviates from the butterfly plate center and the valve body channel center at the same time (i.e. “two offsets”), so that the butterfly plate can quickly disengage from the sealing surface when opening, reducing friction and wear.

Sealing optimization:

The sealing surface is usually made of stainless steel surfacing or silicone rubber material, combined with a double sealing ring design, which effectively solves the problem of shaft hole leakage, and the leakage rate can be controlled at a level close to zero.

Core advantages

High pressure resistance and long life:

Compared with the centerline butterfly valve, the double eccentric structure significantly improves the pressure resistance (nominal pressure can reach Class 300), and the metal valve seat design supports high temperature environment applications (up to 425°C).

Low operating resistance:

The double eccentric structure reduces the opening torque, making operation easier and reducing the failure rate by more than 30%.

Multi-scenario adaptation:

Supports manual, worm gear, pneumatic, and electric drive modes, and is suitable for media including water, oil, gas, and corrosive liquids.

Comparison of application fields

| Field | Specific scenarios |

| Urban construction | Urban water supply and drainage network, building fire protection system |

| Industrial manufacturing | Metallurgical blast furnace cooling water system, power plant circulating water treatment |

| Environmental protection engineering | Sewage treatment plant, water source allocation facility |

| Special working conditions | High temperature steam pipeline (needs to be matched with three eccentric metal hard seals) |

NSW Valve Manufacturer is leader of China Butterfly Valves Factories, our butterfly valves include Double eccentric butterfly valve, triple offset eccentric butterfly valves, high performance butterfly valves, and rubber seat butterfly valves. If you need detail technical data please contact us.

Double Eccentric Butterfly Valve: Engineered Precision for Demanding Flow Control

Optimize pipeline performance and reliability with our advanced Double Eccentric Butterfly Valve. Manufactured with precision engineering and stringent quality control, this valve represents the ideal solution for industries requiring efficient, low-maintenance, and bubble-tight shut-off.

Core Innovation: The Double Offset Advantage

Unlike standard butterfly valves, our design incorporates two distinct eccentricities (offsets):

1. Stem Offset Behind the Disc Centerline: Reduces friction during operation.

2. Stem Axis Offset from the Pipe/Seat Center: Creates a unique camming action.

This double-offset principle ensures the disc lifts completely clear of the resilient seat seal the moment operation begins. The result?

• Dramatically Reduced Seat Wear: Minimizes abrasive contact, extending valve life significantly.

• Ultra-Low Operating Torque: Enables smooth actuation with smaller, more economical gearboxes, pneumatic actuators, or electric actuators.

• Reliable Bubble-Tight Sealing: Achieves exceptional shut-off integrity against liquids and gases in both flow directions.

Minimized Maintenance: Robust design translates to lower lifecycle costs.

Engineered for Performance & Durability:

• Robust Construction: Available in premium materials including Ductile Iron (GGG40/50), Carbon Steel (WCB, LCC), Stainless Steel (CF8/CF8M), and specialized alloys to withstand demanding pressures (PN10/16/25, Class 150/300) and corrosive environments.

• Superior Sealing: Features high-performance resilient seats (EPDM, NBR, Viton® options) or optional metal seats for extreme temperatures/abrasive media.

• Precision Machining: Ensures optimal fit, smooth operation, and consistent sealing performance cycle after cycle.

• Compact & Lightweight: Offers significant space and weight savings over gate or globe valves, simplifying installation and support requirements.

• Global Standards Compliance: Manufactured to meet or exceed API 609, EN 593, ISO 5752, and ISO 5211 specifications.

Your Trusted Source from China:

As a leading China-based manufacturer and global supplier, we combine cutting-edge production technology with rigorous quality assurance. We deliver high-performance double eccentric butterfly valves that meet the most stringent international requirements.

Why Partner With Us?

• Direct Manufacturer Pricing: Competitive value without compromising quality.

• Customization Expertise: Tailor materials, sizes (DN50 – DN1200+), end connections (flanged, wafer, lug), and actuation to your exact needs.

• Consistent Quality: Stringent process controls ensure reliable, batch-to-batch consistency.

• Global Supply Chain: Efficient logistics ensure reliable delivery worldwide.

• Technical Support: Expert guidance for selection, application, and integration.

Ideal Applications:

→ Water & Wastewater Treatment Plants

→ Power Generation (Cooling Water, Fuel Systems)

→ HVAC & District Heating/Cooling

→ Oil & Gas (Refining, Pipelines – moderate services)

→ Chemical & Petrochemical Processing

→ Marine & Offshore Systems

→ Pulp & Paper Industry

→ General Industrial Process Lines

Experience the difference precision engineering makes. Contact us, your dedicated China manufacturer and supplier, for your Double Eccentric Butterfly Valve requirements and discover a smarter solution for critical flow control.

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |