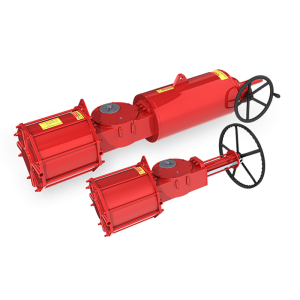

Valve Position Monitor-Limit Switch

Ensure precise valve control and eliminate costly downtime with our advanced Valve Position Monitor and Limit Switch. Engineered for the most demanding environments—from oil and gas to chemical processing and water treatment—this switch delivers unparalleled accuracy, durability, and safety. Its robust design provides clear, reliable feedback on valve position (open/close), making it an indispensable component for your automated process systems.

1. Product Features: Engineered for Durability and Ease of Use

Our limit switch combines a rugged exterior with user-centric design for effortless installation and long-term reliability.

- Rugged Construction: Housings are crafted from die-cast aluminum alloy or 316 stainless steel, with all external metal components made of stainless steel for superior corrosion resistance.

- At-a-Glance Status: A built-in visual position indicator allows for immediate, unambiguous valve status confirmation, enhancing operational safety.

- Maintenance-Free Operation: The unique spring-loaded splined cam design allows for quick initial setting and requires no re-adjustment over time, reducing maintenance efforts.

- Installation Flexibility: Dual or multiple cable entries accommodate various conduit setups, while the anti-loose bolt ensures the upper cover remains secure during service.

- NAMUR Standard Compliance: The connecting shaft and mounting bracket adhere to NAMUR standards, guaranteeing seamless and easy integration with your valve actuators.

2. Intuitive and Durable Display for Instant Readability

Quickly assess valve status from a distance with our highly visible and customizable display options.

- High-Impact Lens: The display window is made from intensive polycarbonate, resistant to impacts, chemicals, and UV exposure.

- Flexible Viewing Angles: Choose between a standard 90° or an optional 180° display to suit your installation sightlines.

- Universal Color Code: Standard yellow for “OPEN” and red for “CLOSE” enable instant, error-free identification by operators.

3. Superior Housing and Sealing for Maximum Protection

The housing is your first line of defense, built to withstand extreme conditions.

- Material Choice: Select between high-strength aluminum alloys or superior corrosion-resistant 316 stainless steel.

- Secure Seal: A zigzag or threaded binding surface (on FL-5 Series) ensures a tight, reliable seal against contaminants.

- Connection Versatility: Standard two electrical interfaces can be expanded to four, with specifications including NPT, M20, and G threads.

- Advanced Sealing Options: Choose from O-rings made of nitrile rubber, EPDM, fluorine rubber, or silicone rubber to match your specific temperature and chemical exposure needs.

4. Precision Stainless Steel Shaft and Environmental Ratings

The core of our limit switch is built for precision and endurance in challenging applications.

- Anti-Corrosion Shaft: A stainless steel shaft, compliant with NAMUR standards or custom-made to your requirements, ensures long-lasting performance.

- Wide Operating Range: Suitable for temperatures from -25°C to 60°C, with options extending from -55°C to 80°C for extreme environments.

- Highest Ingress Protection: Rated IP66/IP67 as standard, with an optional IP68 rating for protection against prolonged submersion.

- Explosion-Proof Certifications: Certified for hazardous areas (ATEX/IECEx equivalents included) with ratings like Exdb IIC T6 Gb, Ex ia IIC T6 Ga, and Ex tb IIC T80 Db.

5. Advanced Anti-Corrosion and Surface Treatment

The exterior is specially treated to resist degradation in corrosive atmospheres.

- Proven Resistance: The surface treatment exceeds WF2 standards, validated by a 1,000-hour neutral salt spray test.

- Multi-Layer Protection: A combination of DuPont resin, anodizing, and a specialized anti-UV coating creates a formidable barrier against corrosion and weathering.

6. Innovative Internal Design for Unmatched Signal Stability

The internal mechanism is meticulously designed to eliminate errors and guarantee accuracy.

- Vibration-Resistant Gearing: A unique, dense gear meshing system allows for precise sensor adjustment and effectively prevents signal deviation caused by vibration, ensuring ultimate signal stability.

- Micro-Angle Precision: High-precision gears and cams work in tandem to achieve a micro-angle differentiation of less than ±2%.

- Fail-Safe Sealing: The upper cover is tightly sealed to the shaft, preventing ingress of water and pollutants even if the external indicator is damaged.

- All-Stainless Internals: All internal metal components, including the spindle, are constructed from stainless steel.

- Flexible Configuration: Choose from mechanical, inductive proximity, or magnetic proximity sensing technology. Options include 8 or 12-terminal blocks, 4-20mA feedback, HART protocol, various bus protocols, and wireless transmission.

Ideal for: Oil & Gas, Chemical Processing, Power Generation, Water Treatment, and Marine Applications.

Upgrade your operational integrity with a Valve Position Monitor that guarantees precision, safety, and reliability. Contact us today to find the perfect solution for your application.

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |