As a leading 2 inch ball valve manufacturer, we specialize in delivering high-performance, reliable 2 inch ball valves tailored to diverse industrial applications. From oil and gas to water treatment, chemical processing to pharmaceutical production, our valves combine precision engineering, premium materials, and strict quality control to meet global standards. Whether you need standard models or custom solutions, we’re committed to being your trusted partner for all 2 inch ball valve needs.

2 inch ball valve

The 2 inch ball valve is a versatile workhorse in industrial piping systems, offering efficient on/off control for liquids, gases, and slurries. Its widespread adoption stems from its balance of flow capacity, durability, and ease of operation—making it indispensable for medium to large-scale projects.

2 Inch

The 2 inch (DN50) nominal size is an industry standard, designed to fit standard 2-inch piping, fittings, and flanges. This size optimizes flow rates while maintaining compact dimensions, making it suitable for applications like water distribution, fuel transfer, and industrial process lines. Our 2 inch ball valves adhere to global dimensional standards (ANSI, DIN, ISO), ensuring seamless integration with existing systems and eliminating compatibility issues.

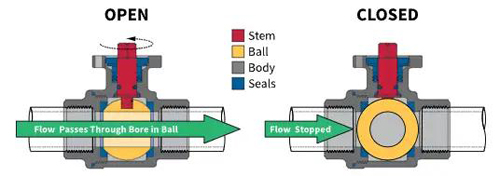

Ball valve

A ball valve operates via a quarter-turn spherical plug, which aligns with the pipe to allow flow or blocks it for shutoff. This simple design delivers key advantages: tight sealing to prevent leakage, quick operation for efficient control, and resistance to corrosion and wear. We offer ball valves in materials like stainless steel (304/316), brass, carbon steel, and PVC/CPVC, each selected to handle specific media—from corrosive chemicals to potable water and high-temperature steam.

2 Inch Ball Valve Product Specifications

| Model | Body Material | Ball Material | Seat Material | Connection Type | Operation Mode | Pressure Rating | Temperature Range | Suitable Media | Certifications |

|---|---|---|---|---|---|---|---|---|---|

| BV-2-SS | 304/316 Stainless Steel | 304/316 Stainless Steel | PTFE/Viton | Threaded (NPT/BSP), Flanged (ANSI 150/300), Welded | Manual (Lever/Handwheel), Electric, Pneumatic | PN16-PN40 / Class 150-300 | -20℃ to 200℃ | Water, Oil, Gas, Chemicals, Steam | ISO 9001, API 6D, CE |

| BV-2-BR | Brass | Brass/Stainless Steel | PTFE | Threaded (NPT/BSP) | Manual (Lever) | PN16 / Class 150 | -10℃ to 120℃ | Potable Water, Air, Light Oil | ISO 9001, CE |

| BV-2-CS | Carbon Steel (A105) | Carbon Steel/Stainless Steel | PTFE/Graphite | Flanged (ANSI 150/300), Welded | Manual, Electric, Pneumatic | PN16-PN64 / Class 150-600 | -29℃ to 300℃ | Crude Oil, Natural Gas, Industrial Fluids | ISO 9001, API 6D, CE |

| BV-2-PVC | PVC/CPVC | PVC/Stainless Steel | EPDM | Threaded (NPT/BSP), Socket Weld | Manual (Lever) | PN10 / Class 150 | 0℃ to 60℃ | Corrosive Chemicals, Wastewater, Acid/Basis Solutions | ISO 9001, NSF |

All valves are manufactured in our ISO-certified facilities, with 100% pressure and leak testing before delivery.

Ball Valve Manufacturer

Choosing the right ball valve manufacturer is critical to ensuring product quality, performance, and long-term reliability. As a dedicated 2 inch ball valve manufacturer, we stand out through our technical expertise, customization capabilities, and customer-centric approach.

Our Core Advantages as a 2 Inch Ball Valve Manufacturer

- Strict Quality Control: We follow ISO 9001 and API 6D standards, with raw material inspections, precision machining (CNC), and rigorous performance testing to guarantee valve durability.

- Flexible Customization: We offer tailored solutions for material upgrades (Hastelloy, super duplex), connection types, actuation (electric/pneumatic), pressure/temperature adaptation (-196℃ to 450℃), and safety features (fire-safe design, anti-static devices).

- End-to-End Support: From pre-sales consultation (material selection, compatibility checks) to after-sales service (installation guidance, replacement parts, 12-24 month warranty), our team provides comprehensive support.

- Efficient Delivery: Standard orders ship in 7-10 working days, with rush service available for urgent needs. Long-term bulk partnerships include preferential pricing and dedicated account managers.

Customization Process for 2 Inch Ball Valves

- Consultation: Share your application details (media, pressure/temperature, installation needs) via our Customization Request Form or direct contact.

- Scheme Design: Our engineers create a technical drawing and quotation within 2-3 working days.

- Sample Approval (Optional): For complex customizations, we provide small-batch samples for testing.

- Production & Testing: Mass production with strict quality checks, including pressure and leak detection.

- Delivery & After-Sales: Ship with technical documents and offer on-site support if required.

Frequently Asked Questions (FAQ)

Do your 2 inch ball valves meet international standards?

Yes—all valves are ISO 9001, API 6D, and CE certified, with NSF options for food/water applications.

What’s the MOQ for custom 2 inch ball valves?

1 pcs for standard customizations; flexible terms for complex designs.

How do I choose the right material for my valve?

Our team assists with material compatibility based on your media (e.g., stainless steel for chemicals, brass for potable water).

What is your warranty period?

12-24 months for standard and custom valves, covering manufacturing defects.

Can you accommodate urgent delivery requests?

Yes. We offer rush production for urgent needs, with delivery in 7–10 working days (for standard customizations). Contact our team to confirm availability.

Ready to Get Started?

As your trusted 2 inch ball valve manufacturer, we’re dedicated to delivering products that enhance operational efficiency and reduce downtime. Whether you need standard 2 inch ball valves or personalized solutions, we have the expertise and resources to meet your requirements.

Post time: Nov-17-2025