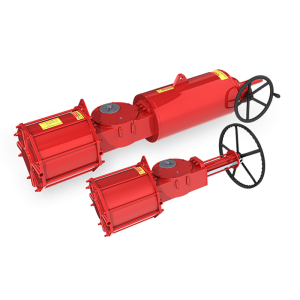

Pneumatic Actuator Gate Valve

In the dynamic landscape of industrial fluid management, the demand for reliable, efficient, and automated valve systems has never been higher. Among the various valve types, the Pneumatic Gate Valve stands out as a cornerstone component, leveraging compressed air power to deliver precise control across diverse applications. This comprehensive guide dives deep into the Pneumatic Actuator Gate Valve and Pneumatic Control Gate Valve, uncovering their technical capabilities, unique advantages, and how they outperform conventional valve solutions in modern industrial settings.

What Is a Pneumatic Gate Valve? Core Definition & Working Principle

A Pneumatic Gate Valve is an industrial control valve that uses compressed air as its power source, paired with a pneumatic actuator to drive the gate plate’s linear lifting movement. This mechanism enables the valve to fully open or close, effectively cutting off or connecting fluid flow in pipelines. Unlike manual Gate Valves, the Pneumatic Actuator Gate Valve eliminates the need for manual operation, supporting remote automation and integration into smart industrial control systems.

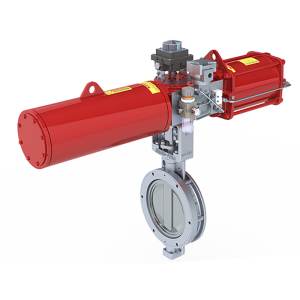

The Pneumatic Control Gate Valve takes this a step further, integrating advanced control accessories (such as positioners and solenoid valves) to achieve precise flow regulation and real-time status monitoring. Its working principle revolves around the synergy between the pneumatic actuator and gate valve body: when compressed air is supplied, the actuator converts pneumatic energy into mechanical force, driving the gate plate to move—ensuring tight sealing when closed and unobstructed flow when open.

Key Technical Specifications of Pneumatic Gate Valve

Understanding the technical parameters of Pneumatic Gate Valve is critical to selecting the right solution for your application. Below is a detailed breakdown of core specs, tailored to industrial standards and custom requirements:

Basic Parameters

|

Parameter Item |

Details

|

|

Valve Type

|

Pneumatic Flanged Gate Valve (Rising Stem/Non-Rising Stem Optional)

|

|

Nominal Diameter (DN)

|

DN15~DN1200 (1/2″~48″)

|

|

Nominal Pressure (PN)

|

PN10~PN420 (Class150~Class2500)

|

|

Connection Method

|

Flange Connection (GB/T 9113, ANSI B16.5, JIS B2220, etc.);

Welded Connection (Butt Weld/Socket Weld, Optional)

|

|

Operation Mode

|

Double-Acting Pneumatic Actuator (Air-to-Open/Air-to-Close); Single-Acting Pneumatic Actuator (Spring Return, Air-Open-Normally-Closed/Air-Close-Normally-Open); Manual Operation Mechanism (Emergency Backup Optional) |

Material & Performance Parameters

• Gate Material: Matches valve body; hard seal versions feature Stellite alloy coating or stainless steel overlay (wear-resistant); soft seal versions use PTFE/PFA/rubber (zero-leakage).

• Sealing Class: Soft seal: GB/T 13927-2008 Class VI (zero leakage); Hard seal: GB/T 13927-2008 Class IV (micro-leakage), upgradable to Class V.

• Operating Temperature: -40℃~+600℃ (standard); -196℃ (cryogenic custom); +800℃ (high-temperature custom with alloy materials).

• Response Time: ≤5s (DN100 and below); ≤8s (DN100~DN300); ≤15s (DN300 and above) at 0.6MPa air supply.

Pneumatic Actuator Specifications

• Air Supply Pressure: 0.4~0.8MPa (standard working pressure)

• Actuator Material: Aluminum Alloy (die-cast, anodized); Carbon Steel (for high-temperature/heavy-load conditions)

• Protection Level: IP65 (standard); IP67/IP68 (special protection optional)

• Accessories: Standard (solenoid valve, air filter regulator); Optional (limit switch, position transmitter, smart positioner, explosion-proof solenoid valve)

Unmatched Advantages of Pneumatic Actuator Gate Valve

What makes the Pneumatic Actuator Gate Valve a preferred choice over competitors? Its unique design and performance features address the pain points of industrial fluid control:

1. Rapid Automated Control & Labor Cost Savings

Equipped with high-efficiency pneumatic actuators, the Pneumatic Gate Valve achieves fast opening/closing responses, eliminating manual operation errors. It integrates seamlessly with PLC systems and industrial IoT platforms, enabling unmanned operation—reducing labor costs by up to 40% compared to manual valves.

2. Superior Sealing & Long-Term Reliability

The dual-seal design (hard/soft options) ensures zero leakage even in high-pressure/high-temperature environments. Hard seal versions use wear-resistant alloy coatings, extending service life by 3x compared to standard valves. Soft seal variants (PTFE/PFA) meet strict zero-leakage requirements for toxic or corrosive media.

3. Low Flow Resistance & Energy Efficiency

In full-open position, the Pneumatic Control Gate Valve features a straight-through flow channel with minimal flow resistance, reducing pressure loss by 20~30% compared to globe valves. This translates to lower energy consumption for fluid transport systems, ideal for large-flow applications like water treatment and oil pipelines.

4. Customizable Design for Extreme Conditions

Unlike one-size-fits-all competitors, our Pneumatic Gate Valve offers extensive customization: cryogenic versions (-196℃) for LNG applications, high-temperature alloy versions (+800℃) for thermal power plants, and corrosion-resistant Hastelloy versions for chemical processing—ensuring optimal performance in any operating conditions.

Top Applications of Pneumatic Control Gate Valve

The versatility of Pneumatic Gate Valve makes it indispensable across key industries:

- Oil & Gas: Crude oil transportation pipelines, refinery reaction systems, and natural gas processing plants.

- Power Generation: Boiler feedwater lines, steam control systems, and cooling water circulation.

- Chemical Industry: Corrosive medium transport (acids, alkalis), high-pressure reaction vessels.

- Water Treatment: Municipal water supply/drainage, sewage treatment plants, and desalination systems.

- Metallurgy: Blast furnace gas control, cooling water pipelines, and molten metal processing.

How to Choose the Right Pneumatic Gate Valve?

Selecting the optimal Pneumatic Actuator Gate Valve requires considering 3 critical factors:

1. Media Characteristics: Choose soft seal (PTFE/rubber) for clean, non-abrasive media; hard seal (alloy-coated) for abrasive/high-temperature media.

2. Operating Conditions: Match nominal pressure/temperature to your pipeline specs (e.g., PN420 for high-pressure oil pipelines; -196℃ for cryogenic LNG).

3. Control Requirements: Opt for single-acting actuators (spring return) for safety-critical applications; add smart positioners for precise flow regulation.

Why Our Pneumatic Gate Valve Stands Out from Competitors

While most manufacturers offer standard Pneumatic Gate Valve, our solution delivers unique value:

• Patented Seal Technology: Our dual-layer soft seal design ensures zero leakage even after 10,000+ cycles—outperforming industry averages by 50%.

• Energy-Saving Actuator: Custom low-consumption pneumatic actuator reduces air usage by 30%, cutting operational costs long-term.

• Global Certification Compliance: Meets API 600, ISO 5211, and CE standards, ensuring compatibility with international industrial systems.

• 24/7 Technical Support: Dedicated engineering team provides custom design, installation guidance, and maintenance services—unlike competitors’ one-time sales models.

The Pneumatic Gate Valve, especially the Pneumatic Actuator Gate Valve and Pneumatic Control Gate Valve, is a game-changer for industrial fluid control—combining automation, reliability, and efficiency to meet the demands of modern manufacturing. Whether you need a standard valve for general applications or a custom solution for extreme conditions, our high-performance pneumatic gate valves deliver unmatched value, backed by technical expertise and global compliance.

Ready to upgrade your fluid control system? Contact us today for a tailored Pneumatic Gate Valve solution that fits your unique needs!

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |