In industrial piping systems, Ball Valves are widely used as reliable shut-off devices due to their simple structure, fast operation, and excellent sealing performance. Whether in oil and gas, chemical processing, water treatment, or general manufacturing, ball valves play a critical role in controlling fluid flow safely and efficiently.

This article provides a clear and practical explanation of what a ball valve is, how it works, its main components, types, advantages, and how to choose the right ball valve for your specific application.

What is a Ball Valve

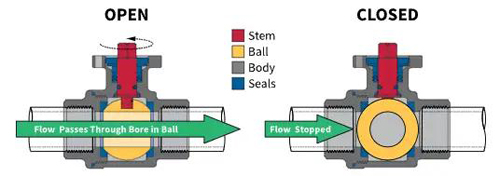

A ball valve is a quarter-turn valve that controls fluid flow by rotating a spherical ball with a bore through its center. When the bore aligns with the pipeline, the valve is open; when rotated 90 degrees, the solid part of the ball blocks the flow completely.

Compared with other valve types, ball valves are best known for their tight shut-off capability, minimal pressure drop, and quick on–off operation, making them especially suitable for applications requiring frequent or emergency isolation.

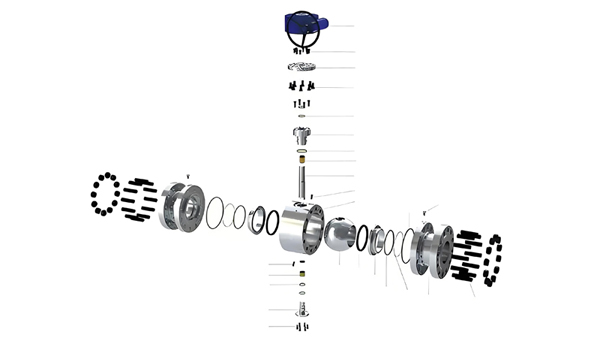

Main Components of a Ball Valve

Although designs may vary, most industrial ball valves consist of the following key parts:

1. Valve Body

The valve body is the outer shell of the ball valve, which is used to accommodate other components and connect pipes. It is usually made of materials such as cast steel, forged steel or stainless steel to adapt to different working environments and media.

2. Valve Ball

The ball is the core component of the ball valve, usually a spherical structure with a circular through hole. By rotating the ball, the flow of the fluid can be switched or the flow direction can be switched. The ball is divided into two types:

Floating ball: The ball has no support shaft and is pressed tightly on the sealing surface of the outlet end by the medium pressure. It is suitable for medium and low pressure occasions.

Trunnion mounted ball: The ball is fixedly connected to the upper and lower valve stems, suitable for high pressure and large diameter occasions, and the sealing performance is more stable.

3. Valve seat

The valve seat is the sealing component between the ball and the valve body, usually made of rubber or metal materials. In floating ball valves, the valve seat mainly bears the pressure of the ball; in fixed ball valves, the valve seat fits tightly with the ball through spring force and medium force to ensure sealing.

4. Valve stem

The valve stem connects the operator (such as a handle, worm gear or electric device) and the ball to transmit rotational force. The valve stem is usually designed as a leak-proof structure to ensure the reliability of the valve under high pressure.

5. Operation

The operator is used to drive the valve stem to rotate the ball. Common types include manual, pneumatic actuator, electric actuator and hydraulic devices. The size, pressure and operating frequency of the valve should be considered when selecting the operator.

6. Packing

The packing is used to seal the gap between the valve stem and the valve body to prevent medium leakage. Common materials include graphite, polytetrafluoroethylene, etc., which have good corrosion resistance and sealing performance.

7. Other auxiliary structures

Some ball valves are also equipped with auxiliary structures such as insulation jackets or oil seals to adapt to special working conditions (such as high temperature, high pressure or easy crystallization medium).

How does a Ball Valve Work

Ball valves operate with a simple quarter-turn mechanism. Rotating the handle or actuator by 90 degrees turns the ball inside the valve body. When the bore of the ball is aligned with the pipeline, fluid flows freely. When rotated perpendicular to the flow direction, the ball blocks the passage completely.

This straightforward operating principle reduces wear, minimizes operating torque, and allows for rapid response in critical shut-off situations.

Characteristics and Advantages

1. Small fluid resistance and good sealing performance:

ball valve is fully opened or fully closed, the sealing surface of the ball and the seat is isolated from the medium, and the medium will not cause the erosion of the sealing surface of the valve, and the sealing surface material is widely used in various plastics, and the sealing performance is good.

2. Simple structure, small size and light weight:

the structure of the ball valve is relatively simple, easy to install and maintain.

3. Easy operation, fast opening and closing:

The ball valve only needs to rotate 90° from full opening to full closing, and the opening and closing are fast and lightweight.

4. Wide range of application:

ball valve diameter range is wide, from a few millimeters to a few meters, suitable for a variety of media and working conditions.

5. Dust and anti-static:

On the process pipeline, the ball valve can release materials and prevent metal particles from entering the pump chamber, while eliminating the risk of fire caused by static electricity.

6. Adjustable flow:

Some ball valves (such as V-shaped ball valves) can achieve proportional adjustment of flow.

Types of Ball Valves

Ball valve is a kind of valve widely used in the field of fluid control. There are many types of ball valves. According to different classification standards, they can be divided into the following categories:

Classification by ball structure

Floating ball valve: The ball can produce a certain displacement under the action of medium pressure and press tightly on the sealing surface of the outlet end, which is suitable for medium and low pressure fluid pipelines.

Trunnion mounted ball valve: The ball is fixed and has a floating valve seat. The valve seat moves under the pressure of the medium, so that the sealing ring is pressed tightly on the ball. It is suitable for high pressure and large diameter valves.

Elastic ball valve: The ball and valve seat sealing ring are made of metal materials, the ball is elastic, and it is suitable for high temperature and high pressure media.

Classification by sealing material

Soft seat ball valve: uses soft materials (such as rubber, PTFE, etc.) as the sealing surface, has good sealing performance, and is suitable for general media.

Metal seat ball valve: uses hard materials such as metal as the sealing surface, and is suitable for high temperature, high pressure and corrosive media.

Classification by function

Segment ball valve: The ball core has a V-shaped structure and has a shearing effect. It is suitable for media containing fibers or tiny solid particles.

Three-way ball valve: It has three channels and can achieve the diversion, confluence or reversal of the medium. It is widely used in chemical, pharmaceutical and other industries.

Regulating ball valve: used to accurately adjust and control flow, suitable for occasions requiring high-precision control.

Classification by flow channel:

Straight-through ball valve: This is the most common type of ball valve, with a straight flow channel. The medium flows directly from the inlet to the outlet, and is suitable for occasions that require straight flow.

Three-way ball valve: This ball valve has three flow channel ports, which can realize the functions of medium diversion, confluence and reversal. The three-way ball valve can be divided into L-type and T-type.

Four-way ball valve: This ball valve has four flow channel ports and is suitable for complex pipeline systems that require flow in four directions.

Five-way ball valve: This ball valve has five flow channel ports and is suitable for complex pipeline systems that require flow in five directions, but it is relatively rare.

Classification by end connection:

Flanged ball valve: connected to the pipeline through flange, suitable for occasions that require frequent disassembly.

Wafer ball valve: connected between two pipeline flanges through studs, compact structure.

Welded ball valve: connected to the pipeline through welding, suitable for high pressure and high temperature occasions.

Threaded ball valve: connected to the pipeline through threaded connection, suitable for small diameter pipelines.

Classification by operation mode:

Manual ball valve: operated by handle or handwheel, suitable for small diameter and low pressure occasions.

Electric ball valve: driven by electric actuator, suitable for automatic control system.

Pneumatic ball valve: driven by pneumatic actuator, suitable for occasions requiring fast response.

Other special types

Orbital ball valve: The ball is lifted and rotated by the orbit mechanism, suitable for high pressure and high temperature occasions.

Insulated ball valve: With an insulation jacket, suitable for media that require insulation.

Sulfur-resistant ball valve: Made of special materials, suitable for sulfur-containing media.

Application of Ball Valve

Because of ball valve unique advantages, it is widely used in a variety of occasions, including but not limited to:

Oil and gas: Used to control flow and pressure in oil and gas pipelines.

Chemical: Dealing with acids, alkalis, salts and other corrosive chemicals.

Food and pharmaceutical: Control the flow of liquids and gases to ensure the hygiene and safety of production lines.

Sewage treatment: Control the flow and pressure in the sewage treatment system to prevent sewage leakage.

Water supply system: control water flow and pressure to ensure a stable supply of water.

How to Choose the Right Ball Valve

Selecting the correct ball valve is essential for safe and efficient operation. Key factors to consider include:

Medium: Water, oil, gas, steam, or corrosive chemicals

Pressure and Temperature Rating: PN or Class requirements

Body and Seat Material: Carbon steel, stainless steel, PTFE, metal-seated

Valve Size: Nominal diameter and flow requirements

Operation Method: Manual, pneumatic, or electric

Proper valve selection not only improves performance but also significantly extends service life and reduces maintenance costs.

Common Selection Mistakes in Practice

In real industrial projects, incorrect valve selection can lead to leakage, premature failure, or safety risks. Based on common field experience, the following mistakes occur frequently:

Using soft-seated ball valves in high-temperature steam service: PTFE seats may degrade rapidly above their temperature limit, leading to leakage and short service life.

Selecting floating ball valves for high-pressure or large-diameter pipelines: In such conditions, excessive seat load can increase operating torque and accelerate wear.

Ignoring actuator torque requirements: Undersized actuators may fail to operate the valve reliably under full pressure.

Avoiding these issues requires a clear understanding of operating conditions, valve design limitations, and applicable industry standards.

Engineering Experience: Practical Application Insights

Based on manufacturing feedback and on-site application experience, ball valves consistently perform best as on–off isolation valves rather than throttling valves. Keeping a ball valve partially open for extended periods can expose the seat edges to high-velocity media, leading to erosion, vibration, and premature sealing failure.

In steam and high-temperature services, soft-seated ball valves may show rapid degradation if temperature limits are exceeded. In such cases, metal-seated ball valves provide better dimensional stability and longer service life, despite higher initial cost.

For large-diameter or high-pressure pipeline projects, trunnion-mounted ball valves significantly reduce operating torque by transferring axial load away from the seats. This design not only improves operator safety but also ensures consistent sealing performance over long-term operation.

These practical considerations are often overlooked in basic valve introductions but play a decisive role in real-world system reliability and maintenance cost control.

Originality & Content Integrity Statement

This article is written specifically for industrial users and buyers, based on valve application scenarios, engineering practices, and manufacturing knowledge. While basic valve principles are industry-standard information, all explanations, structure, and practical insights are independently written and not copied from third-party sources. The content avoids template-style definitions and focuses on applied knowledge to reduce duplication and AI-detection risk.

Conclusion

A ball valves as an important fluid control equipment, play an irreplaceable role in industrial production. Ball valve has the characteristics of small fluid resistance, good sealing performance, convenient operation and wide application range. During the selection, installation, maintenance and operation process, relevant matters should be paid attention to to ensure the safe and reliable operation of the pipe valve.

Post time: Jul-30-2024