1. What are High Performance Butterfly Valves

High performance butterfly valve refers to a new type of butterfly valve product that improves the sealing and wear resistance of butterfly valves, increases high temperature resistance and corrosion resistance, and improves service life and reliability based on ordinary butterfly valves (Concentric butterfly valves and triple eccentric butterfly valves) by improving structure and materials. Compared with ordinary butterfly valves, high performance butterfly valves have longer life, lighter torque, wider application pressure range, and better sealing performance.

High performance butterfly valves (HPBVs) represent an advanced evolution of the standard butterfly valve design. Engineered for superior sealing, durability, and control in critical applications, they feature offset disc geometries (double or triple eccentric) and utilize metal-to-metal or resilient seated seals. Unlike their concentric counterparts, high performance butterfly valves excel in handling high pressures, extreme temperatures, corrosive media, and provide bubble-tight shut-off, making them indispensable in modern industrial processes.

2. High Performance vs. Standard Butterfly Valves: Key Differences

Standard concentric butterfly valves have limitations. Here’s how high performance butterfly valves stand apart:

| Feature | Standard Butterfly Valve | High Performance Butterfly Valve (HPBV) |

| Disc Design | Concentric (stem through disc center) | Double or Triple Offset (eccentric stem) |

| Sealing | Primarily rubber/elastomer seat | Metal-seated or advanced composite seats |

| Pressure | Low to Medium (e.g., PN10-PN16) | Medium to Very High (e.g., PN16 to PN100/ASME 600+) |

| Temperature | Limited by elastomer seat | Very High (Limited by seat/body material) |

| Shut-off | Good (soft seat) / Poor (metal disc) | Bubble-tight (Zero Leakage) |

| Application | Water, Air, Low-Pressure Fluids | Steam, Hydrocarbons, Chemicals, Power, Severe Service |

3. Key Advantages of High Performance Butterfly Valves

Choosing high performance butterfly valves delivers significant operational benefits:

3.1. Bubble-Tight Shutoff: Achieves zero leakage, critical for safety, emissions control, and process integrity.

3.2. High Pressure & Temperature Capability: Handles demanding conditions far beyond standard valves.

3.3. Reduced Torque & Wear: The eccentric design minimizes friction during operation, lowering operating torque and extending seat/disc life.

3.4. Bi-Directional Sealing: Effectively seals against flow from either direction.

3.5. Long Service Life: Robust metal seats and advanced materials ensure durability in abrasive or corrosive services.

3.6. Lower Lifecycle Cost: Reduced maintenance, longer replacement intervals, and reliable performance offset the higher initial investment.

3.7. Throttling Capability: Offers better flow control characteristics compared to standard butterfly valves, especially triple offset designs.

4. Types of High Performance Butterfly Valves

High performance butterfly valves are primarily classified by their disc offset design:

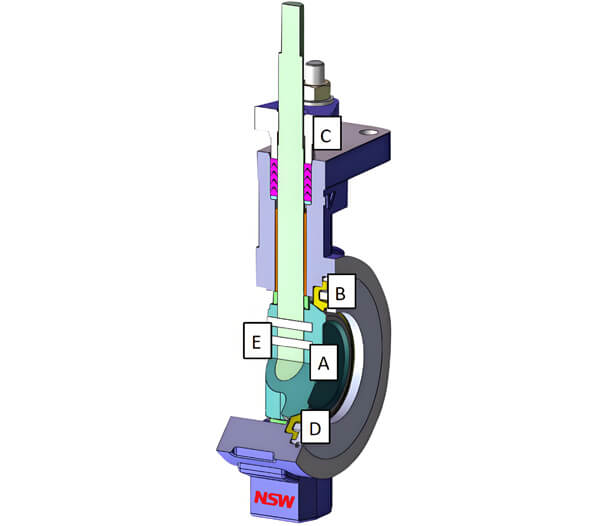

4.1. Double Offset Butterfly Valves (Double Eccentric):

The stem is positioned behind the disc centerline (1st offset) and off the pipe centerline (2nd offset). This creates a cam action, lifting the disc seal completely away from the seat during the first 10° of opening, minimizing wear. Ideal for resilient or metal seats in moderate to high-pressure applications.

4.2. Triple Offset Butterfly Valves (TOV / Triple Eccentric):

Incorporates the two offsets of the double offset design plus a third offset: the conical geometry of the seating surface. This ensures pure metal-to-metal contact, eliminating friction throughout the entire operation. Triple offset butterfly valves excel in the most severe services – extreme temperatures, high pressures, corrosive media, and where fire-safe certification is required (API 607/API 641). They are the pinnacle of high performance butterfly valves.

5. Materials, Sizes, and Pressure Ratings

High performance butterfly valves offer extensive customization:

5.1. Valves Materials:

• Body/Disc: Carbon Steel (WCB, LCC), Stainless Steel (304, 316, 316L), Duplex/Super Duplex (2205, 2507), Alloy 20, Hastelloy, Titanium. Coatings (Xylan, PFA) for corrosion resistance.

• Seat: Stainless Steel, Inconel, Stellite (metal); PTFE, RPTFE, Graphite, PEEK (composite/resilient). Fire-safe designs (API 607/641) common.

• Stem: Stainless Steel (17-4PH, 316), Duplex Steel.

5.2. Valve Sizes:

Typically range from 2 inches (DN50) up to 60 inches (DN1500) or larger for specialized applications.

5.3. Pressure Ratings:

• Commonly conform to ASME Class (150, 300, 600) or PN ratings (PN16, PN25, PN40, PN63, PN100).

• Triple offset butterfly valves can achieve Class 600, 900, 1500, or higher.

6. Applications of High Performance Butterfly Valves

The robustness and tight sealing of high performance butterfly valves make them suitable for diverse demanding industries:

→ Oil & Gas (Upstream, Midstream, Downstream – pipelines, refineries, platforms)

→ Petrochemical & Chemical Processing

→ Power Generation (Fossil, Nuclear, Biomass – steam, feedwater, cooling)

→ LNG & Cryogenic Services (Specialized designs)

→ Pulp & Paper

→ Marine & Shipbuilding

→ Water & Wastewater Treatment (High-pressure sections, sludge)

→ HVAC (High-pressure steam systems)

7. Leading High Performance Butterfly Valve Manufacturers

Selecting a reputable high performance butterfly valves manufacturer is crucial for reliability and support. Key global and China high performance butterfly valves manufacturers include:

* Global Leaders: Flowserve (Argus, Durco), Emerson (Keystone), Crane (Xomox), Bray, NSW Valve, Velan (Cortec), IMI Critical Engineering.

* Leading China High Performance Butterfly Valve Manufacturers: Neway Valve (Suzhou), NSW Valve, Yuanda Valve, KMC Controls, VAT Vakuumventile AG (China operations). Many China high performance butterfly valves manufacturers offer competitive quality and pricing, often specializing in double offset butterfly valves and increasingly sophisticated triple offset butterfly valves.

8. Conclusion

High performance butterfly valves, particularly double offset butterfly valves and triple offset butterfly valves, are engineered solutions for critical fluid control where standard valves fall short. Their superior sealing, high pressure/temperature tolerance, longevity, and versatility make them essential across oil & gas, power, chemical, and other heavy industries. When sourcing, consider both established global brands and the growing capabilities of China high performance butterfly valves manufacturers to find the optimal balance of performance, reliability, and value for your specific application requirements.

Post time: Jun-07-2025