Global Manufacturing Leaders Analysis

1. NICO Valves (USA)

• Core Innovation: Patented Uni-Seal® technology for zero-leakage in mining slurries

• Specialization: High-density slurry valves handling 70%+ solids content

• Certification: API 6D, ASME B16.34

2. NOOK Industries (Germany)

• Core Innovation: Cryo-Treated blades for -196°C LNG applications

• Specialization: Petrochemical & cryogenic service valves

• Certification: TA-Luft, SIL 3

3. NOTON Flow Solutions (USA)

• Core Innovation: Vortex-free V-port design for precision flow control

• Specialization: Power plant fly ash handling systems

• Certification: NACE MR0175

4. FLOWSERVE (USA)

• Core Innovation: AI-powered predictive maintenance systems

• Specialization: Offshore drilling mud valves

• Certification: API 6A, NORSOK

5. NSW VALVE (China)

• Core Innovation: An Emerging Chinese Knife Gate Valve Factory

• Expertise: Mineral Slurry, Abrasive-Resistant Services, Polyurethane-Lined Knife Gate Valves, Slurry Gate Valves, Pneumatic Knife Gate Valves

• Certifications: API 607, API 6FA, CE, ISO 9001

Defining Knife Gate Valve Technology

Knife gate valves utilize a sharpened blade that moves perpendicular to flow direction, excelling in cutting through slurries, fibrous materials, and solids-laden media where conventional valves fail. Their unique shearing action prevents clogging in demanding industrial applications.

Critical Technical Specifications

Blade Engineering Breakthroughs

• Shear Geometry: 3-7° wedge angles optimized for specific media

• Material Science: Stellite 6B coatings for 10x wear resistance

• Sealing Systems: Double O-ring + live-loaded packing

Performance Comparison

| Parameter | Standard Valve | Premium Valve |

|---|---|---|

| Pressure Rating | 150 PSI | 2500 PSI |

| Solids Handling | 40% max | 80% max |

| Actuation Speed | 8 sec | 0.5 sec (pneumatic) |

| Service Temperature | -29°C to 121°C | -196°C to 650°C |

Industry-Specific Solutions

Slurry Knife Gate Valves

• Abrasion-resistant elastomer lining (HR 90+ hardness)

• Bolt-on wear sleeves for maintenance reduction

• Designed for phosphate, tailings, and dredging applications

Pneumatic Knife Gate Valves

• ATEX/IECEx certified actuators

• Triple-redundant position sensing

• 100,000+ cycle life in cement plants

Selection Methodology

Application-Driven Criteria

• Mining: Prioritize tungsten carbide seats + 3mm blade clearance

• Wastewater: Require FDA-compliant EPDM seals

• Chemical Processing: Specify PTFE encapsulation for acid resistance

Certification Checklist

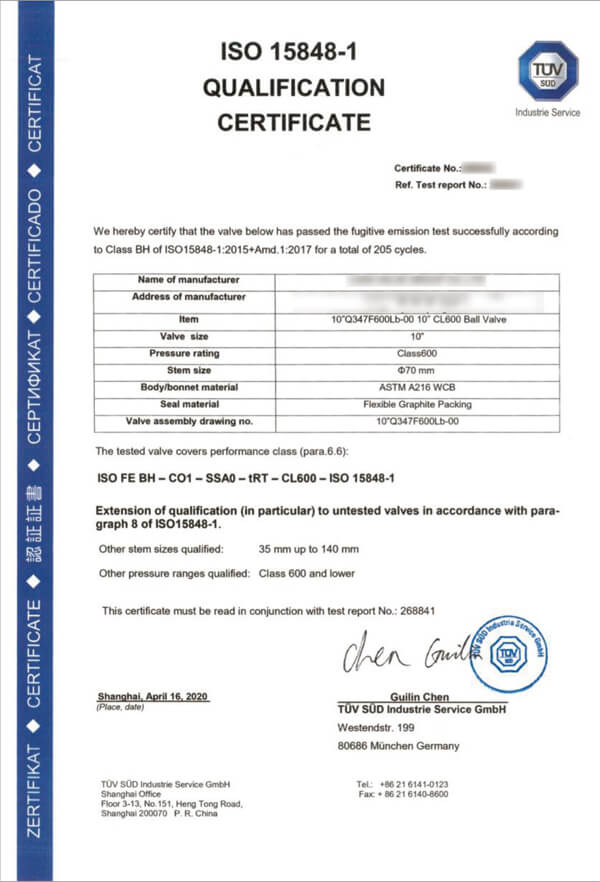

• ISO 15848-1 (fugitive emissions)

• AWWA C520 (waterworks standard)

• Fire-safe API 607 testing

Post time: Aug-11-2025