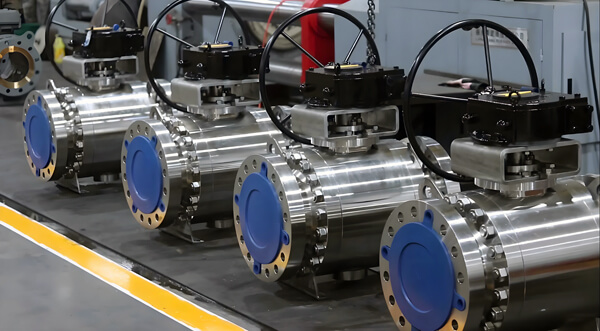

Ball valves are widely used in natural gas pipelines and various industrial systems due to their simple structure, quick operation, low fluid resistance, reliable sealing, long service life, and high durability. However, after long-term use, frequent operation, or under harsh conditions, ball valves may wear out or become damaged. When this happens, replacing the ball valve is essential to maintain system safety and operational efficiency. This guide offers a detailed overview of how to change a ball valve, including key precautions and best practices.

Why Change a Ball Valve?

Change a Ball Valve also means Replace a Ball Valve. There are several reasons why replacing a ball valve becomes necessary:

1. Aging and Damage:

Improper maintenance or extended use can lead to internal wear, corrosion, or failure of valve components, requiring replacement to ensure proper function.

2. Technology Updates:

As technology evolves, newer and more efficient ball valves are developed. Upgrading to modern valves can enhance performance, increase productivity, and improve output quality.

3. System Upgrade or Modification:

Changes in production processes or facility upgrades may require ball valves with different specifications or connection types to fit the updated system.

When Should You Change a Ball Valve?

How to determine whether the ball valve needs to be replaced, consider following situations:

- Enhancing System Safety:

An aging or faulty valve can cause leaks or failures, posing safety risks. Installing a new valve significantly reduces these dangers.

- Extending Service Life:

Replacing worn-out valves prevents localized damage from affecting the entire system, thereby extending its overall lifespan.

- Improving Energy Efficiency:

Modern ball valves are designed to reduce fluid resistance, which helps lower energy consumption.

- Reducing Maintenance Costs:

Replacing old valves decreases the need for frequent repairs, reducing long-term maintenance expenses.

Step-by-Step Guide: How to Change a Ball Valve

1. Preparation

Close the upstream and downstream valves (such as gate, butterfly, plug, or globe valves) to isolate the ball valve that needs replacement. Ensure that all relevant power sources are shut off and that no media can leak from the pipeline. Gather all necessary tools and replacement parts.

2. Remove the Old Valve

Carefully disassemble the old ball valve. Take this opportunity to clean any debris or residue inside the pipeline.

3. Select and Install the New Ball Valve

Choose a new ball valve that matches the system requirements and specifications. Install it according to the manufacturer’s guidelines and industry standards.

4. Testing and Verification

After reinstalling the power supply, conduct a comprehensive test of the newly installed ball valve to ensure it operates correctly and meets performance standards.

Helpful Tip: If you only need to replace a ball valve handle, it is possible to do so without removing the entire valve from the pipeline. However, ensure that:

• The ball valve has a sealing function (confirm with the Ball Valve Manufacturer).

• The valve is in the closed position.

Important Notes When Replacing a Ball Valve

1. Safety Precautions

Always ensure the system is fully shut down before replacing a ball valve. Close all upstream and downstream valves to prevent media leakage.

Note: This step is critical—especially when dealing with toxic or hazardous media. Failure to isolate the valve properly can lead to serious accidents and property loss.

2. Clean Pipeline Residue

After removing the old valve, clean any debris inside the pipeline. Repeat the cleaning process after installing the new valve.

Note: leftover debris (such as welding slag) can damage the sealing surfaces of the new ball valve or other downstream valves, resulting in leakage or valve failure.

3. Compatibility Check

When selecting a new ball valve, make sure its specifications are compatible with the existing system.

4. Post-Installation Testing

Always perform a full performance test after completing the replacement to verify the new valve’s functionality and seal integrity.

By following these steps and guidelines, you can effectively Replace a Ball Valve, improve system performance, and ensure safe and efficient industrial operations.

Post time: Aug-20-2025