Selecting the right ball valve involves understanding critical differences between manufacturers, suppliers, and distributors. This guide answers essential questions to help you make an informed choice for industrial valve procurement.

Manufacturers vs. Suppliers: What’s the Difference

A ball valve manufacturer owns production facilities, overseeing everything from design to quality control. Suppliers or distributors resell third-party products. While suppliers offer faster delivery, manufacturers provide:

- Lower prices by eliminating middlemen

- Customized solutions for unique applications

- Strict quality control and technical expertise

Why Partner Directly with Ball Valve Manufacturers

1. Superior Quality Control: In-house production ensures adherence to ISO/API standards.

2. Cost Efficiency: Direct pricing saves 20-40% vs. distributor quotes.

3. Customization: Design valves for specific pressure, temperature, or material needs.

4. Technical Support: Expert guidance on valve selection and maintenance.

Chinese Ball Valve Manufacturers vs. Global Competitors

China dominates industrial valve production with compelling advantages:

- Cost-Effectiveness: Competitive pricing without quality compromise.

- Scalability: Large factories handle bulk orders with rapid turnaround.

- Certifications: Top manufacturers comply with ANSI, DIN, and API standards.

- Technology: Automated production and R&D investments ensure cutting-edge solutions.

While European/North American brands excel in niche high-precision valves, Chinese manufacturers offer broader capabilities for most industrial applications at better price points.

4 Reasons to Choose Chinese Ball Valve Manufacturers

1. Aggressive Pricing: Save 20-40% over Western alternatives.

2. Advanced Infrastructure: Modern factories ensure consistent output and scalability.

3. Global Compliance: Expertise in international standards for seamless integration.

4. Export Proficiency: Streamlined logistics to 100+ countries.

How to Select a Reliable Chinese Manufacturer

Follow this 6-step verification:

1. Check Certifications: Validate ISO, API 6D, or CE compliance.

2. Audit Production Capacity: Confirm ability to handle your order volume.

3. Request Samples: Test materials, pressure rating, and durability.

4. Compare Quotes: Prioritize value (quality + service) over the lowest price.

5. Review Testimonials: Check case studies from global clients.

6. Verify After-Sales: Ensure responsive technical support and warranty coverage.

Key Takeaway

Partnering directly with a ball valve manufacturer—especially in China—delivers optimal control over quality, cost, and customization. Their blend of advanced factories, cost efficiency, and technical expertise makes them ideal for industrial projects requiring reliability and value.

Recommended Ball Valve Supplier

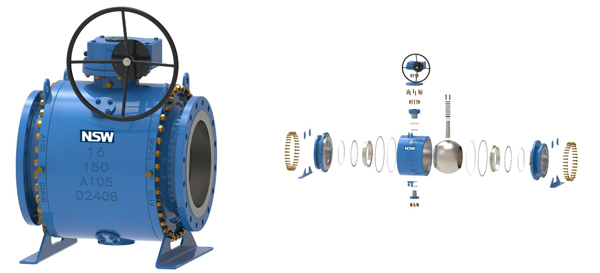

Professional ball valve supplier and factory – NSW Valve Manufacturer

NSW is One of the Top 10 Ball Valve Brand In China. They have modern factories and advanced valve processing equipment. They specialize in producing various types of ball valves and ball valves of various materials, such as trunnion mounted ball valves, floating ball valves, top entry ball valves, carbon steel ball valves, stainless steel ball valves, duplex steel ball valves, cryogenic ball valves, high temperature ball valves, etc.

NSW strictly follows the design standards of API6D and ISO14313 and the testing standards of API 6D and API 598. At the same time, NSW has also passed other international tests such as ISO 15848-1, ISO 15848-2, API 607, API 6FA and other certifications.

Post time: Jun-27-2025