In the vast world of fluid control and plumbing systems, ensuring flow moves in one direction is critical. Among the various types of check valves designed for this purpose, the ball check valve stands out for its simplicity, reliability, and effectiveness. This guide provides an in-depth look at ball check valves, explaining their operation, benefits, and how to source them from quality suppliers globally and in China.

What is a Ball Check Valve

A ball check valve is a type of check valve, or non-return valve, that uses a spherical ball to control the direction of fluid flow. Its primary function is to permit flow in one direction while automatically preventing backflow (reverse flow) when the fluid pressure drops. The design is straightforward: a ball sits within a chamber, and fluid pressure lifts it to allow flow; when pressure decreases, gravity or backpressure forces the ball back into its seat, sealing the valve. They are commonly used in applications ranging from water pumps and fuel systems to chemical processing and automotive applications.

Components of a Ball Check Valve

The simplicity of a ball check valve is reflected in its minimal number of parts. Key components include:

Body/Housing:

The main chamber that contains all other components, typically made from metals like brass or stainless steel, or plastics like PVC or CPVC, depending on the application.

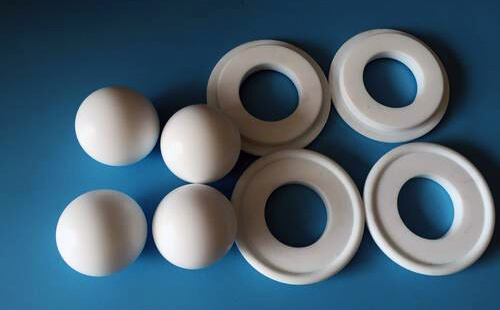

Ball:

The free-moving spherical obturator. It is usually made from a durable, corrosion-resistant material that is often denser than the fluid it controls (e.g., rubber-coated metal, synthetic ruby, or PTFE).

Seat:

The rim where the ball rests to form a seal and stop backflow. The seat is often beveled to guide the ball into a perfect seal and can be made from a softer material or include an O-ring to ensure a tight closure.

Spring (Optional):

In some designs, a spring is used to assist in closing the valve, especially in applications where gravity cannot be relied upon (e.g., horizontal pipelines or low-pressure systems).

How a Ball Check Valve Works and Its Function

The working principle of a ball check valve is elegantly simple and based on fluid dynamics and pressure differentials.

Forward Flow (Open State): When upstream pressure (inlet pressure) exceeds the downstream pressure and the force required to lift the ball (and overcome the spring force if present), the ball is pushed away from its seat. This creates an opening, allowing fluid to flow around the ball and through the valve.

No Flow / Backflow Prevention (Closed State): When the upstream pressure drops, equalizes, or reverses (backflow), the combination of gravity and the backpressure of the fluid pushes the ball back onto its seat. The ball acts as a plug, creating a tight seal that effectively blocks any reverse flow, protecting sensitive equipment upstream.

Its core function is automatic, pressure-activated one-way flow control without the need for manual operation or external control systems.

Advantages of Ball Check Valve

Ball check valves offer several distinct benefits:

Simple Design: With very few moving parts, they are easy to manufacture, understand, and maintain.

Reliability: The straightforward mechanism offers high reliability with minimal failure points.

Suitability for Viscous Fluids: They are excellent for handling slurries, wastewater, and other viscous fluids that might cause other check valve types (like swing or wafer check valves) to stick or fail.

Quick Response: They provide fast closing action, effectively minimizing water hammer (though not as well as some silent check valve designs).

Versatility: Available in a wide range of materials, sizes, and pressure ratings to suit diverse industries.

Ball Check Valve vs. Ball Valve

This is a common point of confusion due to the similar names, but they are fundamentally different.

Feature |

Ball Check Valve |

Ball Valve |

|---|---|---|

| Primary Function | Automatic prevention of backflow | Manual on/off control of flow |

| Operation | Self-actuated by flow pressure | Manually operated via a lever or handle |

| Flow Direction | Allows flow in one direction only | Allows flow in both directions when open |

| Design | Contains a free-floating or spring-loaded ball | Contains a pivoting ball with a bore through it |

In short: A ball valve is for manually stopping or starting flow, while a ball check valve is for automatically ensuring flow only goes one way.

Ball Check Valve vs. Check Valve

A ball check valve is actually a sub-type of the broader check valve category. The term “check valve” is generic. Here’s how the ball design compares to other common check valve types:

Vs. Swing Check Valve:

Swing check valves use a flapper that swings on a hinge. They typically have a higher flow capacity and lower pressure drop but are not ideal for viscous fluids or erratic flow patterns where the flapper can chatter. Ball check valves handle viscosity better.

Vs. Lift Check Valve:

Lift check valves use a piston or disc that lifts vertically. They are similar in function but the ball design can often handle more contaminants and debris without fouling.

Vs. Wafer Check Valve:

Wafer check valves are thin, lightweight valves placed between flanges. Ball check valves are generally more robust but often have a larger installation footprint.

The ball type is often chosen for its ability to handle challenging media.

Known International Ball Check Valve Suppliers

The global market features several established and reputable manufacturers:

AVK: A world leader in valve manufacturing, known for high-quality valves for water and gas industries.

Emerson (ASCO): Provides a wide range of fluid control valves, including specialized check valves.

SPX FLOW (APV, Waukesha Cherry-Burrell): Offers sanitary and industrial ball check valves for the food, dairy, and pharmaceutical sectors.

Swagelok: Renowned for high-purity and high-pressure ball check valves for instrumentation and sampling systems.

Parker Hannifin: A major player in motion and control technologies, offering a vast portfolio of valves for numerous applications.

China Ball Check Valve Suppliers

China is a major global hub for valve manufacturing, offering a blend of quality and cost-effectiveness. Key suppliers include:

• NSW Valve: A well-known Chinese manufacturer offering a comprehensive range of valves, including various check valves, for industrial use.

• Shanghai LV Machine Equipment: Supplies a variety of fluid control equipment and valves to the international market.

• Zhejiang OMI Valve Co., Ltd.: Specializes in brass and stainless steel valves, including ball check valves, for plumbing, HVAC, and industrial applications.

• Moorflex Fluid Technology Co., Ltd: Focuses on manufacturing pneumatic and hydraulic components, including check valves.

Sourcing from Alibaba or Made-in-China.com: These B2B platforms host thousands of valve factories and trading companies. When sourcing here, it is critical to:

• Verify supplier credentials (e.g., Business License, Factory Audit Reports).

• Request material certifications (e.g., CF8M for 316 SS).

• Clearly specify pressure ratings, sizes, and material standards (ANSI, DIN, JIS).

• Order samples first to test quality before committing to a large order.

Post time: Aug-27-2025