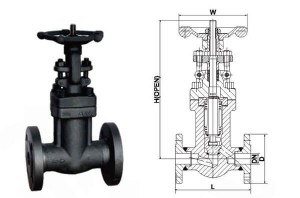

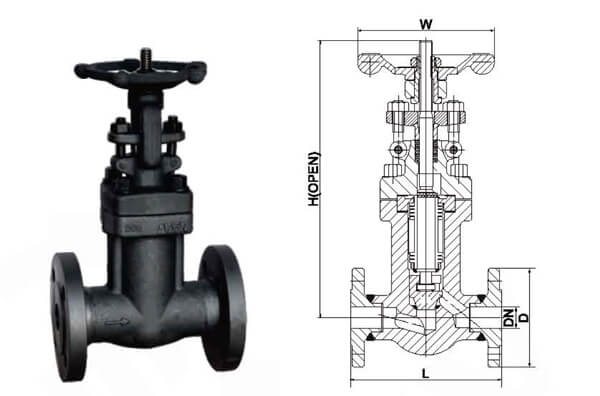

API 602 Bellows Sealed Globe Valve

Bellows Sealed Bonnet Globe Valve Products Specifications

Products Range:

Size: DN1/2” to DN50 (1/2″~2″)

Pressure rating: CL150-CL2500, CL800

Temperature: -196 to 593 °C

Materials:

Body: Forged Steel: A105, LF2, F5, F11, F22, A182 F304 (L), F316 (L), F347, F321, F51), Alloy 20, Monel, Inconel

Bellows: SS304, SS316, SS321, SS316Ti, Monel

Standards:

| Design & manufacture | API 602, MSS-SP-117, ASME B16.34, BS 5352 |

| Face-to-face | ASME B16.5 |

| End Connection | - Flange Ends to ASME B16.5 |

| - Socket Weld Ends to ASME B16.11 | |

| - Butt Weld Ends to ASME B16.25 | |

| - Screwed Ends to ANSI/ASME B1.20.1 | |

| Test & inspection | API 598 |

| Fire safe design | / |

| Also available per | NACE MR-0175, NACE MR-0103, ISO 15848 |

| Other | PMI, UT, RT, PT, MT |

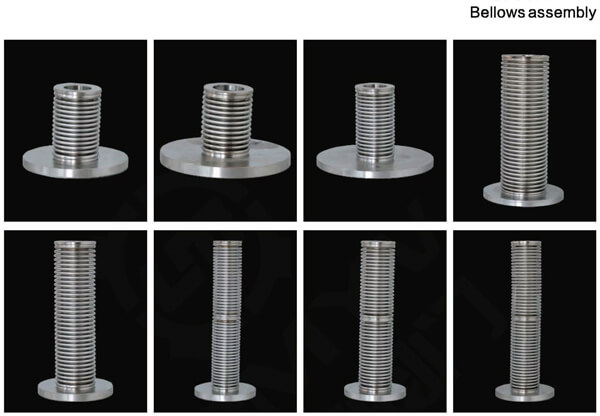

Design of NSW Bellows Sealed Globe Valve

• Bellows is the key part of bellows sealed globe valves, which is welded to both the valve bonnet and valve stem, with automatic roll welding. The metal bellows can keep the stem part 100% Zero Leakage.

• Double seal design (bellows+packing). Bellows from a metal seal to prevent leakage, and packing can provide seal if the bellows failed.

Design Features:

1.Forged Steel,Outside Screw and Yoke,Rising Stem

2.Bellows Sealed Bonnet (Double Seal)

3.Reduced Bore or Full Port,

4.Socket Welded,Threaded,Butt Welded, Flanged End

5.SW, NPT, RF or BW

7.Solid Wedge,Renewable Seat Rings, Sprial Wound Gasket

8. Low Fugitive Emissions

Application:

Thermal oil system, Steam system, Hot and Cold water system, etc.

Introducing the API 602 Bellows Sealed Globe Valve: Ultimate Zero-Leakage Performance for Critical Service

Ensure Safety, Compliance, and Reliability with Premium Forged Steel Construction

The API 602 Bellows Sealed Globe Valve represents the pinnacle of leak-tight integrity and robust performance for demanding applications in the oil & gas, petrochemical, power generation, and refining industries. Engineered to meet the rigorous requirements of the API 602 standard for compact forged steel gate, globe, and check valves, this valve is specifically designed to eliminate fugitive emissions at the stem seal – the most common leakage point in traditional valves.

The Superior Bellows Seal Advantage:

• Zero Fugitive Emissions: The core innovation lies in its metal bellows seal. This critical component forms a hermetic, welded barrier between the process fluid and the atmosphere. The bellows compresses and extends with each valve stroke, completely isolating the stem. This design is essential for compliance with stringent environmental regulations (like TA Luft and EPA LDAR programs) and safeguarding personnel in hazardous environments.

• Unmatched Longevity: Our bellows are meticulously crafted from high-grade stainless steel, employing multi-ply, convoluted designs rigorously tested for tens of thousands of cycles. This ensures exceptional fatigue resistance and a long service life, minimizing costly downtime and replacements.

• Enhanced Safety: By eliminating stem packing as a potential failure point, the Bellows Sealed Globe Valve significantly reduces the risk of hazardous fluid release, protecting both personnel and the environment, especially when handling toxic, corrosive, or volatile media.

API 602 Compliance Guarantees Quality:

• Robust Forged Steel Body: Manufactured from high-quality ASTM materials (A105, A182 F304/F316, F91, etc.), ensuring superior strength, pressure integrity, and resistance to thermal shock and corrosion.

• Precision Machining: Strict adherence to API 602 dimensional and tolerance standards guarantees reliable performance and interchangeability.

• Rigorous Testing: Every valve undergoes comprehensive shell tests, seat tests (bubble-tight shutoff required), and bellows integrity testing per API 602, ASME B16.34, and often ISO 15848-1 for fugitive emissions certification.

Key Features & Benefits:

• Compact Design: Ideal for space-limited installations typical in critical process lines.

• Globe Valve Precision: Excellent for throttling and flow regulation, providing precise control with minimal seat erosion.

• Wide Application Range: Suitable for steam, hydrocarbons, chemicals, and other aggressive fluids across various pressure classes (ASME 1500 to 4500 common).

• Bonnet Options: Standard bolted bonnet design ensures secure containment. Extended bonnet versions available for high-temperature insulation or cryogenic service.

• Low Maintenance: The welded bellows seal drastically reduces routine maintenance compared to traditional packed stem valves.

• End Connections: Flanged (RF, RTJ), socket weld, or threaded ends available to suit your piping specifications.

Applications Demanding Zero Leakage:

• Critical process isolation and control

• VOC (Volatile Organic Compound) service

• Toxic or lethal media handling

• High-pressure steam systems

• Refinery and petrochemical processing units

• Power plant boiler feed and turbine systems

• Any application requiring compliance with strict emission standards

Choose the API 602 Bellows Sealed Globe Valve for Uncompromising Sealing Performance

When absolute stem sealing integrity, environmental responsibility, operational safety, and long-term reliability are non-negotiable, the Bellows Sealed Globe Valve built to API 602 standards is the definitive solution. Engineered for the most severe service conditions, it delivers peace of mind and protects your assets, people, and the planet.

Upgrade your critical isolation points. Specify API 602 Bellows Sealed Globe Valves today.

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |