What is a Pressure Relief Valve?

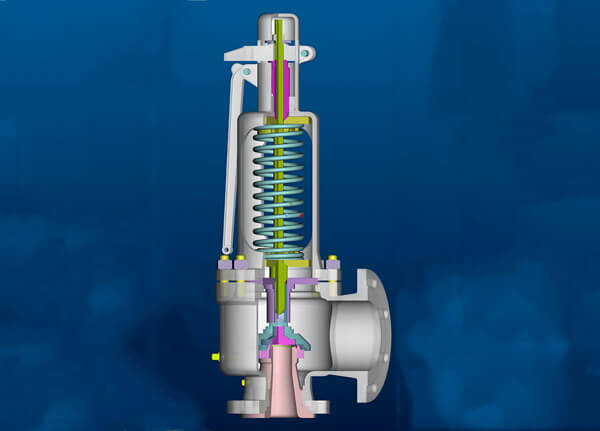

A Pressure Relief Valve (PRV) is an automatic safety device designed to protect enclosed systems, equipment, and pipelines from damage caused by excessive pressure. It consists of calibrated springs and hydraulic control elements. When system pressure reaches the valve’s pre-set threshold, the valve activates to release excess pressure.

How Does a Pressure Relief Valve Work?

When steam pressure beneath the valve disc exceeds the spring’s compressive force, the disc lifts. Upon opening, discharged steam acts against the disc holder ring via the lower adjusting ring’s reaction force, causing rapid full opening. As the disc rises further, steam impacts the upper adjusting ring, redirecting flow vertically downward. The resulting reactive thrust pushes the disc upward, maintaining sufficient lift height within a specific pressure range. As pressure vents, system pressure gradually decreases. The spring force then overcomes both steam pressure and reactive thrust, closing the valve securely.

Relief Valve Function: Core Purpose & Importance

The primary function of a Pressure Relief Valve (often termed a Safety Valve) is to prevent overpressure in system high-pressure zones, safeguarding equipment integrity. By autonomously regulating pressure, PRVs vent fluid once a critical pressure is reached, maintaining operational pressure within safe limits. This ensures stable equipment performance, prevents failure due to overpressure, and mitigates system-wide leaks or operational disruptions.

The Critical Importance of Pressure Relief Valves

PRVs play an indispensable role in industrial systems. Without them, abnormal pressure surges in high-pressure systems can cause catastrophic pipe bursts, equipment destruction, and severe safety hazards. Such failures lead to significant financial losses and unquantifiable safety risks. Thus, correct PRV selection, regular inspection, maintenance, and timely replacement of defective units are imperative.

Safety Pressure Relief Valve: Terminology & Scope

Broadly, “Safety Valve” encompasses pressure relief valves. However, regulatory definitions specify that valves directly installed on steam boilers or Class I pressure vessels – requiring regulatory body certification – are strictly termed Safety Valves. Others are generally classified as Relief Valves or Pressure Relief Valves.

Safety Valve vs. Pressure Relief Valve: Key Differences

Though structurally and functionally similar (both automatically discharge media upon exceeding set pressure), Safety Valves and Pressure Relief Valves are distinct per the ASME Boiler and Pressure Vessel Code, Section I:

Safety Valve: A pressure-actuated valve featuring a “pop” (rapid full-opening) action. Primarily used for gas or steam service.

Relief Valve (Pressure Relief Valve): A pressure-actuated valve opening proportionally as pressure exceeds the set point. Mainly used for liquid (fluid) service.

Despite these definitions, confusion persists due to functional overlap and interchangeable use in some plant specifications, often leading to operational issues.

Pressure Relief Valve Selection Principles

Selecting the correct valve type is critical for safety and performance:

1. Steam Boilers: Typically use Open, Full-Lift Spring-Loaded Safety Valves.

2. Liquid Service: Generally require Low-Lift Spring-Loaded Safety Valves (Relief Valves).

3. Air/Gas Service: Use Closed, Full-Lift Spring-Loaded Pressure Relief Valves.

4. LPG Tankers (Road/Rail): Require Full-Lift, Internally Mounted Pressure Relief Valves.

5. Oil Wellhead Outlets: Typically need Pilot-Operated Pressure Relief Valves.

6. Steam Power Plant High-Pressure Bypass: Use Pilot-Operated Valves with combined safety and control functions.

7. Regular Testing Requirement: Valves needing manual testing require a lever (lifting device). This allows partial lifting at ≥75% set pressure to verify operation.

8. High-Temperature Service (>300°C for closed valves, >350°C for open valves): Must use Valves with Heat Sinks/Cooling Fins.

Safety Valve Standards: Global Frameworks

Key governing standards include:

JB/T 2203-1999 (China – General):

Common domestic standard for spring safety valve dimensions. Limitations exist (max DN200 for full-lift, DN100 for low-lift, missing DN65/DN125). Industry practice often exceeds size limits (up to DN250 low-lift, DN400 full-lift). Inconsistent flange dimensions (e.g., DN150 variants) necessitate standardization updates for interchangeability.

API 526 (US – Flanged Valves):

Standard for imported chemical/petrochem equipment. Covers DN25-DN200 (1″-8″), 2-42MPa, throat sizes D-T (9.5-146mm). Scientifically defines specs by throat size. Gaining traction in China via trade/equipment localization. Not yet a Chinese national standard.

Pilot-Operated Valves (Anderson Greenwood Model):

Increasingly used for high capacity, low operating differential, near-zero leakage, and backpressure insensitivity (e.g., natural gas pipelines). Lacks dedicated Chinese standards; most manufacturers follow Anderson Greenwood designs. Urgent need for domestic standards (e.g., by HF General Machinery Research Institute).

HT Series (Aerospace Research Institute 11th – China):

Unique system including HTO (standard), HTB (balanced bellows), HTR (venting), HTN (special), HTGS (high-perf steam), HTXY (liquid), HTXD (pilot-operated). HTXD shares dimensions with Anderson Greenwood; others differ from API/JB standards. Crucial to verify compatibility during selection.

Conclusion

Pressure Relief Valves are fundamental safety components preventing equipment damage and ensuring system stability by controlling overpressure. Their critical role in industrial operations directly impacts productivity and safety outcomes. Organizations must prioritize correct PRV selection, precise installation, rigorous maintenance schedules, and proactive replacement to guarantee reliable, safe, and efficient system performance.

Post time: Jul-29-2025