In the world of industrial automation and fluid control, pneumatically actuated ball valves are vital components. This article delves into the intricacies of Pneumatic Ball Valves, their operation and applications, with a particular focus on their role as shutoff valves (SDVs) and control ball valves.

Learn about pneumatic ball valves

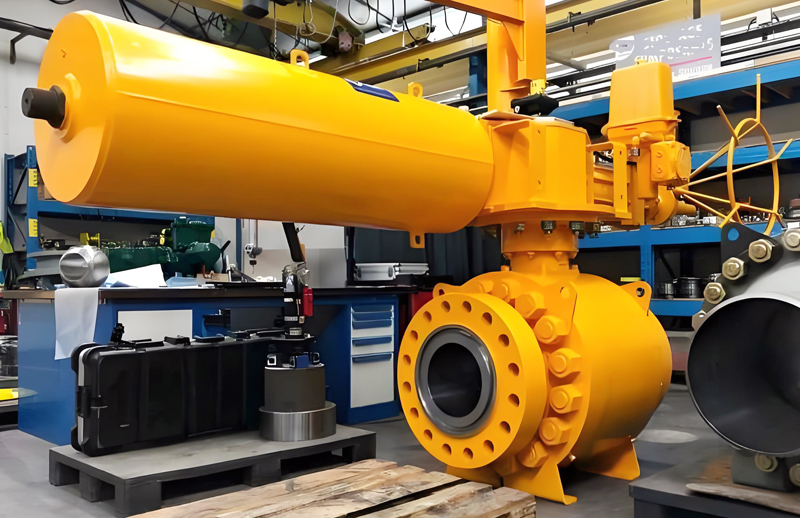

The pneumatic ball valve is a quarter-turn valve that utilizes a spherical disc, called a ball, to control the flow of fluid. The ball has a hole in the center that allows fluid to pass through when the valve is open. When the valve is closed, the ball rotates 90 degrees, blocking the flow of fluid. This design provides a reliable and effective way to control fluid flow in a variety of applications.

Components of Pneumatic Ball Valve

Valve Ball: The core component that regulates flow. The surface of the ball can be made of a variety of materials, including stainless steel, plastic or brass, depending on the application.

Valve Body: The valve body houses the ball and is usually made of durable material to withstand high pressures and corrosive environments.

Pneumatic Actuator: This device converts pneumatic energy into mechanical motion, enabling the valve to open and close. Actuators can be single-acting or double-acting, depending on the application requirements.

Stem: The Stem (Shaft) connects the actuator to the ball, enabling the transfer of motion.

Seat Seal: Seals are critical to preventing leakage and ensuring the valve operates efficiently.

The role of pneumatic actuators

Pneumatic actuators are essential components for the operation of pneumatic ball valves. They use compressed air to generate motion, which is then transmitted to the valve. Actuators can be remotely controlled, allowing for the automation of various industrial processes.

Types of Pneumatic Actuators

Single-Acting Actuators: These actuators use air pressure to move the valve in one direction, and when the pressure is released, the spring returns it to its original position.

Double-Acting Actuators: These actuators use air pressure to move the valve in both directions, providing better control and faster operation.

Post time: Jan-29-2025