In industrial valve systems, double eccentric butterfly valves deliver precision flow control for demanding applications. Engineered to minimize wear and maximize sealing efficiency, they outperform standard valves in critical settings like water treatment, chemical processing, and power generation. This guide covers their design, advantages, and ideal use cases.

Butterfly Valves: Core Principles

Butterfly valves regulate flow via a rotating disc with a quarter-turn mechanism. Their quick operation suits high-volume systems, including oil/gas pipelines, HVAC, and wastewater management.

Key Butterfly Valve Types

1. Concentric Butterfly Valves:

Disc centered on the valve body.

Low-pressure use; limited sealing.

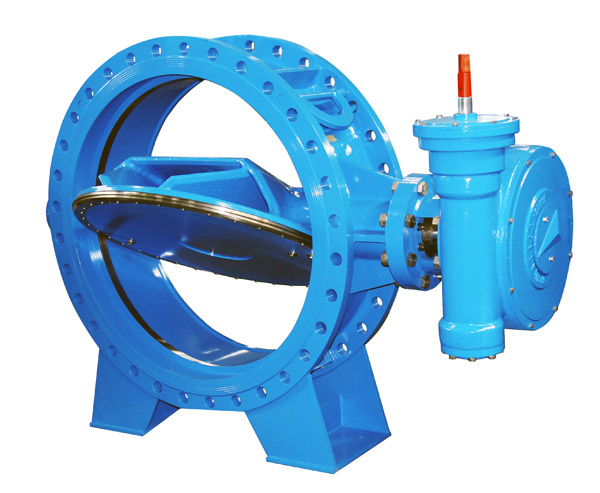

2. Double Eccentric Butterfly Valves:

Disc offset from body/shaft centerlines.

Reduced friction, robust sealing, high performance.

3. Triple Eccentric Butterfly Valves:

Added conical-seat offset.

Extreme-pressure/heat applications.

4. High Performance Butterfly Valve:

High-performance butterfly valve refers to the traditional butterfly valve, which has improved sealing, wear resistance, high temperature resistance and corrosion resistance by improving the structure and materials. It has double eccentric structure and triple eccentric structure.

Double Eccentric Design Explained

The valve’s performance stems from two strategic offsets:

Shaft-to-Body Offset: Separates the shaft from the valve body centerline, lifting the disc away from the seat during rotation to prevent friction.

Disc-to-Body Offset: Positions the disc off-center, enabling cam-action sealing for zero-leakage closure.

Critical Features

Zero-Wear Operation: Disc avoids seat contact until full closure.

High-Pressure Tolerance: Seals reliably up to 150+ Class ratings.

Corrosion Resistance: Compatible with stainless steel, special alloys.

Compact & Lightweight: Saves space and simplifies installation.

4 Major Benefits of Double Eccentric Valves

1. Superior Seal Integrity:

Bubble-tight shutoff prevents leakage in critical systems.

2. Reduced Operating Torque:

Lower actuation energy cuts costs and extends actuator life.

3. Extended Service Life:

Minimal wear ensures decades of reliable operation.

4. Application Versatility:

Handles steam, acids, slurries, and temperatures from -50°C to 600°C.

Double vs. Triple Eccentric Valves: Key Differences

| Factor | Double Eccentric | Triple Eccentric |

|---|---|---|

| Sealing | Excellent for most uses | Zero-leakage in extreme conditions |

| Cost | Cost-effective | Higher investment |

| Maintenance | Low | Moderate complexity |

| Applications | Water, chemicals, power | Refineries, ultra-high pressure |

Selecting a Reliable Valve Manufacturer

Partner with certified suppliers who offer:

Industry Compliance: API 609, ISO 9001, TA-Luft, and fire-safe certifications.

Material Options: Carbon steel, Duplex, Hastelloy, or epoxy-coated bodies.

Customization: Lug/wafer designs, gearbox/actuator compatibility.

Global Support: Technical assistance and rapid spare-part services.

Conclusion

Double eccentric butterfly valves optimize flow control with durable, low-maintenance performance across industries. While triple eccentric valves excel in extreme settings, the double eccentric design balances cost, versatility, and reliability for 90% of industrial needs. Partner with certified manufacturers to ensure quality and longevity.

Post time: Jun-10-2025