A Bellows Sealed Globe Valve is a type of globe valve that utilizes a metal bellows as its primary sealing element. Its core component is the metal bellows. Through automatic roll welding, the bellows creates a hermetic metal barrier between the fluid medium and the atmosphere, ensuring zero leakage at the valve stem. This design not only enhances the sealing performance of the valve but also significantly extends its service life.

Working Principle of the Bellows Sealed Globe Valve

The working principle of the Bellows Sealed Globe Valve is similar to that of a standard globe valve. The valve stem is driven up and down by a handwheel or actuator, which in turn moves the valve disc (or plug) to open or close the valve. When the disc moves upwards, fluid can flow through the valve; when the disc moves downwards, it seals tightly against the valve seat, blocking fluid flow. The bellows plays a critical sealing role in this process, ensuring excellent sealing performance under all operating conditions.

The working principle can be divided into three main stages:

1. Opening Process: When the actuator operates, it drives the push-rod, causing the bellows to axially compress or extend (deform). Simultaneously, this drives the closure member (disc/plug). During this stage, medium pressure acting on the inner cavity of the bellows creates a self-balancing state.

2. Closing Process: Reverse operation resets the closure member. Reliance on both the elastic recovery force of the bellows and the medium pressure ensures complete tightness.

3. Sealing Achievement: The unique metal-to-metal contact sealing design achieves zero leakage standards (ANSI/FCI 70-2 Class V).

Main Components of a Bellows Sealed Globe Valve

The Bellows Sealed Valve is a specially structured control valve, primarily composed of the following components:

1. Main Structural Parts:

• Valve Body: Typically made of stainless steel or carbon steel.

• Bonnet: Connected to the valve body via flanges or threads.

• Sealing Assembly: Includes the stuffing box and sealing gaskets.

2. Core Functional Components:

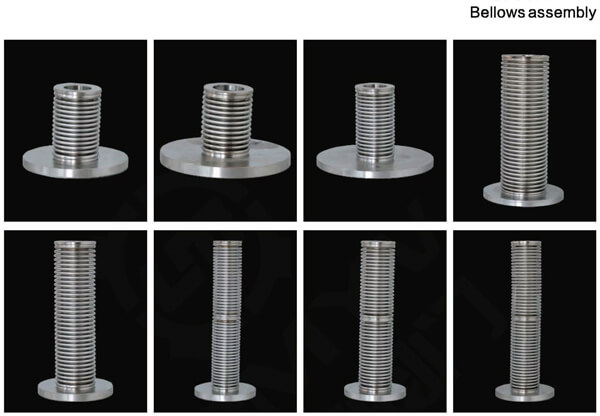

• Bellows: Formed by welding multiple layers of thin-walled metal cylinders.

• Valve Stem and Actuator Connection Point.

• Closure Member (Disc/Plug).

Structural Features of the Bellows Sealed Globe Valve

The structural design of the Bellows Sealed Globe Valve possesses the following distinctive features:

1. Dual Sealing Design:

It incorporates a dual-seal structure consisting of the bellows and stem packing. Even if the bellows fails, the stem packing prevents leakage, ensuring sealing reliability.

2. Corrosion Resistance:

The bellows is typically made of stainless steel, offering excellent corrosion resistance suitable for various media.

3. Long Life Design:

Hydraulically formed bellows possess high cycle fatigue life, capable of withstanding frequent opening and closing operations.

4. Stem Protection:

The lower end of the bellows is welded to the valve stem, protecting it from erosion by the process fluid and extending the stem’s service life.

5. Seat Hardfacing:

The sealing surfaces are overlay welded with cobalt-based (Co-based) hard alloy, providing excellent wear resistance, corrosion resistance, and anti-friction properties, resulting in a long service life.

Technical Advantages

• Zero Leakage Performance:

The metal bellows completely eliminates stem leakage, making it ideal for toxic, flammable, or high-purity media.

• Corrosion & Wear Resistance:

The valve stem undergoes quenching and tempering plus surface nitriding. Seating surfaces are overlay welded with hard alloys (e.g., Co-based), resisting corrosive fluids and particle erosion.

• Suitability for Extreme Conditions:

Temperature range from -40°C to 425°C, especially suitable for high-temperature thermal oil systems (low pressure, high temperature conditions).

• Easier Maintenance:

The bellows design reduces the need for packing replacement, lowering long-term maintenance costs.

Differences Between Bellows Sealed Globe Valves and Standard Globe Valves

1. Unique Design & Dual Seal Assurance

The uniqueness of the Bellows Sealed Globe Valve lies in its zero-leakage design. Renowned for its zero-leakage capability and dual-seal assurance, it guarantees stem sealing safety. This design constructs a robust metal barrier between the fluid medium and the atmosphere via automatic roll welding, ensuring zero leakage. It demonstrates significant superiority compared to traditional globe valves. Should the bellows fail, the stem packing acts as a backup seal, maintaining zero leakage. Its robust and durable bellows seal structure not only ensures stem sealing performance but also provides maintenance-free operation.

2. Structure & Wear Resistance

The Bellows Sealed Globe Valve features a rational structure with no fluid loss, reducing energy consumption. This valve offers a rational structure, reliable sealing, excellent performance, and an aesthetically pleasing appearance. The absence of fluid loss minimizes energy waste and enhances plant equipment safety. Its sealing surfaces utilize Co-based hard alloy overlay welding, providing outstanding wear resistance, corrosion resistance, and anti-friction properties, reducing maintenance needs and costs. This extends service life, decreases repair frequency, and lowers operational costs.

3. Corrosion Resistance Compared to Standard Globe Valves

The valve stem of the Bellows Sealed Globe Valve undergoes quenching and tempering plus surface nitriding, endowing it with exceptional corrosion and friction resistance. In contrast, the standard sealed globe valve (i.e., the standard globe valve) also has certain characteristics. It is popular due to advantages like low friction during opening/closing, durability, and ease of manufacture and repair. However, it also has some drawbacks, such as high fluid resistance and insufficient long-term sealing reliability. Overall, the standard globe valve remains a widely used and generally reliable valve type. Nevertheless, standard globe valves suffer from disadvantages like high fluid resistance and poor long-term sealing performance, making them less excellent than Bellows Sealed Globe Valves.

4. Application Advantages & Comparison

In industrial applications, external leakage problems caused by aging stem packing in standard globe valves are common. Bellows Sealed Globe Valves excel in industrial applications, avoiding the potential leakage issues inherent in standard globe valves. These leaks may involve high-temperature, highly toxic, flammable, explosive, or radioactive media, causing not only severe environmental pollution but also potentially significant personal injury and property loss. The design of the Bellows Sealed Globe Valve completely resolves this issue. Its bellows seal structure renders the valve virtually maintenance-free, significantly improving energy efficiency, enhancing production equipment safety, and reducing repair costs and the need for frequent maintenance. Consequently, it provides a clean working environment and lowers maintenance costs, offering a solution that is both clean and safe.

Application Fields of Bellows Sealed Globe Valves

Leveraging their exceptional sealing performance and reliability, Bellows Sealed Globe Valves are widely used in numerous industries including petroleum, chemical, pharmaceutical, fertilizer, and power generation, particularly in applications demanding the highest sealing integrity.

1. Chemical Industry

Within the chemical industry, Bellows Sealed Globe Valves control the flow of corrosive media. For example, a chemical plant uses these valves for chlorine gas transfer. The valve employs LCB low-temperature corrosion-resistant steel for the body, with a bellows made of Hastelloy C-276 and PTFE V-ring seals, featuring a dual-seal structure that effectively prevents chlorine leakage.

2. Pharmaceutical Industry

The pharmaceutical industry imposes extremely high requirements for valve cleanliness and sealing. The dual-seal design and corrosion resistance of Bellows Sealed Globe Valves make them an ideal choice. For instance, a pharmaceutical company uses them in thermal oil systems. These valves feature an optimized streamlined design with low pressure drop. The streamlined design allows for a self-draining system, offering performance superior to other globe valve types.

3. Power Industry

In the power industry, Bellows Sealed Globe Valves are used in steam pipelines and boiler systems to ensure efficient steam transfer and safe control. For example, a power generation company employs them on steam lines. These valves effectively prevent steam leakage, improving energy utilization efficiency.

4. Food & Beverage Industry

Strict hygiene and safety requirements characterize the food and beverage industry. The sealing performance and corrosion resistance of Bellows Sealed Globe Valves enable them to meet these specific needs. For instance, a brewery uses them for steam control during the production process, ensuring a clean and safe production environment.

Installation and Maintenance of Bellows Sealed Globe Valves

1. Installation Precautions

• Installation Direction: Install the valve according to the fluid flow direction, ensuring flow travels from bottom to top to minimize fluid resistance within the valve.

• Connection Method: Select the appropriate connection method (e.g., flanged or welded) based on actual operating conditions.

• Environmental Requirements: The installation location should avoid high temperatures, humidity, and corrosive environments to extend valve service life.

2. Maintenance Recommendations

• Regular Inspection: Periodically inspect the sealing performance of the bellows to ensure no leakage.

• Cleaning & Lubrication: Regularly clean the valve exterior and lubricate the valve stem to prevent corrosion and sticking.

• Emergency Handling: If bellows leakage is detected, use the emergency gland for temporary sealing to prevent further leakage.

3. Key Maintenance Points

• Failure Prevention: Bellows fatigue fracture is a primary failure mode; regular inspection is required. Some valve designs feature replaceable bellows cartridges for easier servicing.

• Condition Suitability: For high-temperature environments (e.g., >200°C), prioritize full stainless steel Bellows Sealed Globe Valves to avoid packing degradation.

Conclusion

Bellows Sealed Globe Valves, through innovative sealing technology, solve the external leakage problems of traditional valves. They excel in sealing performance, safety, and durability, making them a frequently chosen valve type in demanding fields such as chemical processing and energy.

Post time: Aug-08-2025