In the world of fluid control, where precision and reliability are paramount, the valve seat is the unsung hero. This critical component is the foundation of a valve’s sealing performance, directly impacting its leak-tight integrity, service life, and overall safety. Whether you’re an engineer, a maintenance technician, or a procurement specialist, understanding the Valve Seat is essential for optimal system performance.

What is a Valve Seat?

A valve seat is a fundamental internal component of a valve that forms one half of the sealing pair. It is the stationary surface upon which the valve’s closure element—such as a ball valve seat interacts with the ball, or a globe valve seat with the plug—makes contact to stop fluid flow.

Think of it as a precisely machined “chair” for the moving part. When the valve is closed, the closure element sits firmly against the valve seat, creating a seal that isolates the upstream side from the downstream side. The quality of this interface dictates the valve’s leakage class and its ability to hold pressure.

The Critical Functions of a Valve Seat

The valve seat is a multi-talented component, performing several vital functions:

1. Primary Sealing: Its core mission is to create a leak-tight seal with the closure element, preventing fluid from passing when the valve is in the closed position.

2. Supporting the Closure Element: The valve seat bears the force exerted by the closure element and the system pressure, providing stable support when the valve is shut.

3. Guidance and Alignment: In certain valve types like Globe Valve Seats, the seat often helps guide the plug or disc, ensuring perfect alignment for a uniform and effective seal every time.

4. Integral Part of the Pressure Boundary: The seat is a crucial element of the valve’s pressure-containing body, requiring immense strength and stability, especially in high-pressure applications.

Valve Seat Materials: Choosing the Right Fit

Selecting the correct valve seat material is a balancing act between chemical compatibility, temperature, pressure, wear resistance, and cost. The choice fundamentally defines the valve’s application range.

Soft Seats (Polymeric):

• PTFE (Teflon): Offers exceptional chemical resistance, a very low friction coefficient, and a broad temperature range. It’s the go-to choice for corrosive services and applications demanding bubble-tight shut-off.

• NBR (Nitrile Rubber): Provides excellent resistance to oils and fuels, making it common in petroleum, water, and air applications.

• EPDM (Ethylene Propylene Diene Monomer): Known for superior weather, ozone, and steam resistance, ideal for hot water, cooling systems, and various chemicals.

• Silicone Seals: Providing excellent resistance to heat, chemicals, and microbial growth. They are commonly used in applications from -100°C to +316°C (-148°F to +600°F)

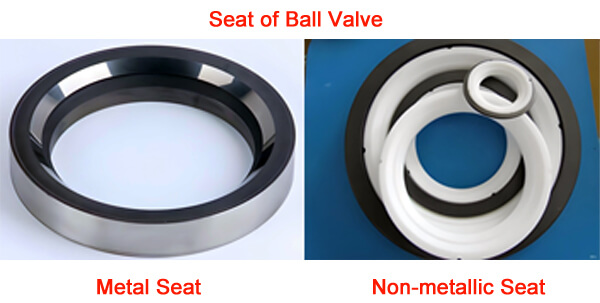

Metal Seats:

• Stainless Steel (304, 316): A versatile, corrosion-resistant option for water, steam, oil, and many chemicals.

• Alloy Steel (13Cr, 17-4PH): Used for enhanced strength and hardness in high-pressure and high-temperature environments.

• Duplex Stainless Steel: Combines high strength with superior corrosion resistance, particularly against chloride-induced stress corrosion cracking.

• Specialty Alloys (Monel, Hastelloy): Employed for extreme corrosive services, such as seawater, hydrofluoric acid, or hot sulfuric acid.

• Cobalt-Based Alloys (Stellite): Applied as a hard-facing material on the seat surface to provide extreme wear and erosion resistance.

The Fundamental Trade-off: Soft seats generally achieve bubble-tight sealing but have limited temperature and pressure thresholds. Metal seats withstand harsh, high-temperature/pressure environments but achieving zero leakage can be more challenging.

Valve Seat Temperature Limits

A seat’s ability to withstand temperature is dictated by its material.

• Soft Seats: Typically operate within a moderate temperature band. EPDM is generally limited to ~150°C, NBR to ~80°C, while PTFE can handle up to ~260°C. Beyond these points, polymers degrade, harden, or permanently deform, causing seal failure.

• Metal Seats: Are designed for high-temperature service, capable of operating from cryogenic temperatures to over 800°C, depending on the alloy. The material must retain its strength and resist oxidation and creep at these extremes.

Valve Seat Pressure Ratings

The valve seat must structurally withstand the system’s operating pressure without deforming or failing.

• Low-Pressure Systems: Both soft and standard metal seats are suitable.

• Medium-to-High-Pressure Systems: Require robust metal seats. The design, such as the use of seat backstops or reinforced structures, becomes critical to prevent seat blow-out.

• Ultra-High-Pressure Systems: Demand specially engineered metal seats, often from high-strength alloys, with ultra-precise surface finishes to prevent media from being injected into microscopic surface imperfections.

It is crucial to remember that temperature and pressure ratings are interdependent; high temperature reduces a material’s strength.

Valve Seat Structures Across Different Valve Types

The design and operation of a valve seat vary significantly depending on the valve type. Here’s a look at some of the most common configurations.

Ball Valve Seat

The Ball Valve Seat is a ring-shaped disc, typically two, housed in the valve body on either side of the ball.

• Structure: Often “floating,” where system pressure or spring force pushes the seat against the ball to form a seal. This design can provide dual-directional or unidirectional sealing.

• Sealing Mechanism: Both soft and metal seats are widely used. In fire-safe designs, the soft seat will char in a fire, allowing a secondary metal-to-metal seal between the ball and a secondary seat land.

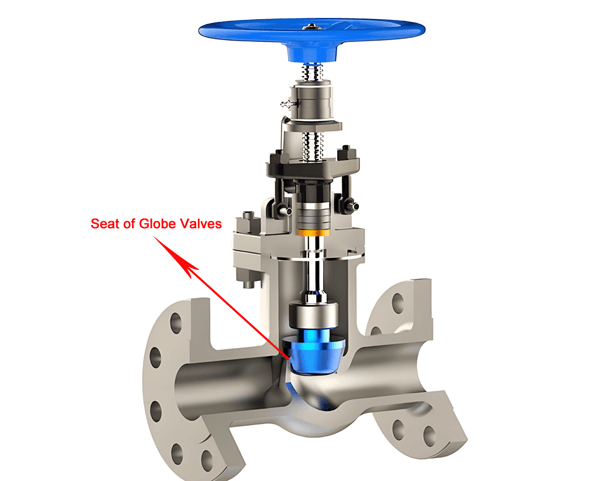

Globe Valve Seat

The Globe Valve Seat is typically a stationary ring, integrated into the valve body, against which the plug or disc closes.

• Structure: The seat is often a separate, renewable ring that is threaded, pressed, or welded into the valve body. This allows for easy maintenance and replacement.

• Sealing Mechanism: Usually involves a flat or conical plug mating with a corresponding seat. The combination of materials can range from soft to hardened metals, providing excellent throttling and sealing capabilities.

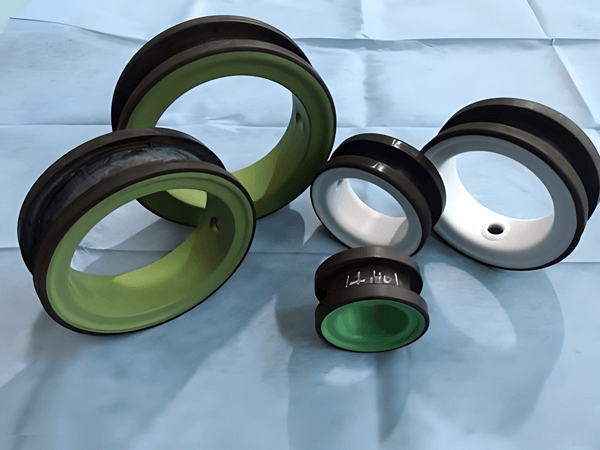

Butterfly Valve Seat

A Butterfly Valve Seat is a continuous circular ring that lines the inner diameter of the valve body.

• Structure: The disc rotates a quarter-turn within this seat. The seat can be a pressed-in ring, bonded (vulcanized) to the body, or a fully retained, replaceable design.

• Sealing Mechanism: Soft seats (EPDM, PTFE) are most common, where the perimeter of the disc compresses into the resilient seat. Metal-seated butterfly valves use complex geometric contact points for tight shut-off in high-temperature duties.

Other Critical Valve Seat Structures

• Check Valve Seat: Functions similarly to a globe valve seat, designed for automatic operation. The disc (or wafer) seals against the seat to prevent backflow, requiring a fast response and tight seal.

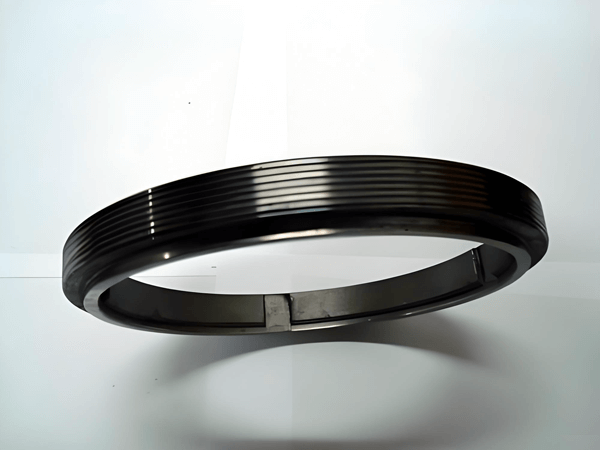

• Gate Valve Seat: Usually consists of two parallel, stationary rings in the valve body. The gate wedges between them. The seats are often integral to the body or welded-in for robustness in high-pressure isolation services.

• Plug Valve Seat: In a lubricated plug valve, sealing is achieved by injecting a sealant between the plug and body. In a non-lubricated version, a sleeve made of PTFE or similar material acts as the resilient valve seat.

Conclusion

From the humble faucet to complex industrial plants in the chemical, power, and aerospace industries, the valve seat is a cornerstone of fluid control system integrity. By carefully considering its material, design, and operational limits, you can ensure the safety, efficiency, and longevity of your fluid handling systems.

Post time: Oct-29-2025