What Are Valve Balls?

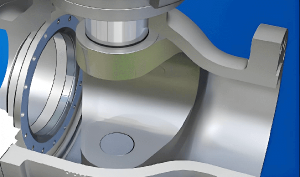

The core component of a ball valve is the valve ball (or ball valve sphere). Its design directly determines the valve’s sealing performance, flow control capability, and service life.

Shape & Precision:

Standard balls feature either full-bore or reduced-bore designs. A full-bore ball has a bore diameter matching the pipeline’s internal diameter (e.g., 2 Inch ball has a 2 Inch bore), ensuring near-zero flow resistance. Machining precision must achieve IT6-IT7 grade (per ISO 286), with a surface roughness ≤0.8μm (Ra) to minimize wear and ensure smooth operation.

Role of Valve Balls

Valve balls are the primary sealing and flow control element within a ball valve. Rotating the ball 90 degrees opens or closes the flow path. Their precision surface and material integrity are paramount for leak-tight shut-off and modulating flow control.

Valve Ball Materials

Stainless Steel (304/316):

Offers excellent corrosion resistance, widely used in chemical, petrochemical, and food processing industries.

Carbon Steel with Nickel Plating:

A cost-effective solution offering moderate corrosion protection, commonly used in low-pressure water systems.

Ceramic (e.g., Alumina, Zirconia):

Provides exceptional resistance to abrasion, corrosion, and high temperatures (up to 1200°C), but exhibits higher brittleness (referencing “Valve Engineering Handbooks”). Ideal for severe slurry and high-temperature services.

Types of Valve Balls

O-Port Ball:

Standard spherical ball with a cylindrical bore, used in most floating and trunnion ball valves.

V-Port Ball:

Features a V-shaped notch in the bore, enabling precise flow control (characterized by an equal percentage flow characteristic), used specifically in V-port ball valves.

C-Port Ball:

Bore shaped like a “C”, primarily used for specific multi-port applications.

U-Port Ball:

Bore shaped like a “U”, used in multi-port valves for specific flow diversion requirements.

Floating Ball:

The ball is not mechanically fixed to the stem and relies on downstream pressure to force it against the seat for sealing. Common in smaller sizes.

Trunnion Mounted (Fixed) Ball:

The ball is supported by trunnion bearings at the top and bottom, reducing operating torque and seat load, especially critical in high-pressure and large-diameter applications.

Three-Way Balls:

T-Port Ball:

Directs flow between any two ports or can shut off all flow.

L-Port Ball:

Connects the center port to either of the two side ports but not all three simultaneously.

Critical Note: Solid vs. Hollow Balls

Some manufacturers, particularly in China, produce hollow valve balls primarily as a cost-saving measure.

Hollow balls have a significantly lower pressure rating due to their internal cavity and do not comply with the design requirements of API 6D (Pipeline Valves).

Procurement and inspection personnel must explicitly confirm with the manufacturer whether the valve balls supplied are solid or hollow. Using hollow balls in pressure applications poses a severe safety risk.

Valve Ball Machining and Surface Treatment

To ensure valve ball hardness, extend valve service life, and enhance wear resistance, specialized surface treatments (coatings) are often applied:

Hardfacing:

Techniques like Stellite overlay (e.g., Stellite 6, 21), NiCrBSi alloys (e.g., Ni60), or Tungsten Carbide (WC) coatings dramatically increase surface hardness and abrasion resistance.

High-Chrome Alloys:

Coatings like 13Cr provide enhanced corrosion and erosion resistance.

Precision grinding and lapping (post-coating if applied) are essential to achieve the required surface finish (Ra ≤0.8μm) and sphericity for optimal sealing.

Valve Ball Interaction with Other Components (Valve Seats)

The performance of a ball valve hinges on the precise interaction between the valve ball, seats, and stem.

Valve Ball and Seat Sealing Systems

Soft Seating (PTFE/Elastomers like NBR, EPDM):

Achieves very low leakage rates (≤10⁻⁶ m³/s, ISO 5208 Class A).

Limited temperature range (typically ≤200°C).

Excellent for tight shut-off in clean services.

Metal Seating (e.g., Stellite, 316SS, Hardfaced):

Suitable for high temperatures (up to 540°C+) and abrasive/corrosive services.

Initial leakage rate is higher than soft seats but can achieve low leakage (Class B/C/D) after precise lapping of ball and seat to extremely fine finishes (Ra ≤0.4μm).

Essential for fire-safe applications.

Valve Balls in Floating vs. Trunnion Mounted Ball Valves

The ball support mechanism defines two major valve types:

Floating Ball Valves (Typically ≤DN200):

The ball is free to float slightly downstream. System pressure pushes the ball against the downstream seat to create a seal.

Lower operating torque (e.g., ≤50N·m for DN100 per API 6D calculations).

Limitation: Prone to excessive seat load and potential “jamming” under high pressure; generally limited to PN40 (Class 300) ratings.

Trunnion Mounted Ball Valves (For High Pressure & Large Bore):

The ball is fixed on trunnion bearings. Seats are spring-loaded and pressurized against the ball.

Provides highly reliable sealing, significantly lower operating torque (especially for large sizes), and suitability for very high pressures (PN100 / Class 600 and above).

Typical Application: Critical oil & gas pipelines (e.g., DN300 trunnion valves rated for 10MPa used in major projects like the West-East Gas Pipeline).

Valve Balls in Metal-Seated vs. Soft-Seated Ball Valves

The choice of ball material and surface treatment is closely linked to the seat type:

Soft-Seated Valves:

Often use standard stainless steel (304/316) balls. The soft seat conforms easily to the ball surface.

Metal-Seated Valves:

Require hardened balls (e.g., through hardfacing like Stellite or WC) to withstand the high contact stress and abrasion against the equally hard metal seat. Precision surface finish matching is critical.

Industry Application Data Comparison

| Valve Type | Max. Pressure (MPa) | Temperature Range (°C) | Cycle Life (10k cycles) | Typical Seating |

|---|---|---|---|---|

| Floating (PTFE) | ≤4.0 | -20 to +200 | 10 – 15 | Soft (PTFE) |

| Trunnion (Metal) | ≤42.0 | -196 to +540 | 20 – 30 | Metal (Stellite/HF) |

| Source: API 6D-2021 Standard (American Petroleum Institute) | ||||

Maintenance: Warning Signs of Ball Damage

Scratch Depth >0.1mm:

Indicates significant surface damage impairing sealing; ball replacement is mandatory (per ASME B16.34 guidance).

Operating Torque Increase >20%:

Signals potential seat hardening/deformation, excessive friction, or ball eccentricity requiring investigation.

Conclusion: The Performance Ceiling

The design, material selection, and manufacturing precision of the valve ball fundamentally define the performance limits (“ceiling”) of any ball valve. From selecting the optimal alloy and coating to pairing it with the correct sealing system, every step must be meticulously matched to the specific service conditions. Even minor deviations in ball quality or compatibility can lead to premature valve failure. Investing in high-integrity valve balls is paramount for safety, reliability, and longevity in demanding applications.

Post time: Aug-01-2025