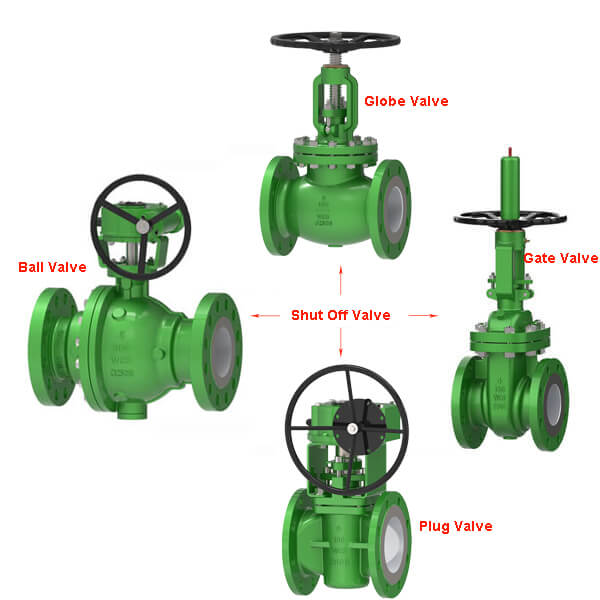

Introduction to Shut Off Valves

Shut off valves are critical components in plumbing, industrial, and irrigation systems. They control the flow of liquids or gases, allowing for safe maintenance, emergency shutdowns, and system regulation. Choosing the right type of valve can impact efficiency, cost, and longevity. Among the most popular options is the Shut Off Valve-Ball Valve, known for its reliability and ease of use.

Overview of Ball Valves

A ball valve utilizes a rotating ball with a bore to control flow. When the handle is turned, the ball rotates to either allow or block fluid passage. Its simple design makes it highly effective for shut off valve ball valve applications.

Features of Ball Valve Shut Off

• Quick Operation: A quarter-turn fully opens or closes the valve.

• Durability: Constructed from materials like brass, stainless steel, or PVC.

• Leak Resistance: Provides a tight seal, minimizing leakage risks.

• Versatility: Suitable for water, gas, and chemical applications.

Types of Ball Valves

There are several ball valve types, including:

• Full Port Ball Valve: Offers minimal flow restriction.

• Standard Port Ball Valve: More compact but with slightly reduced flow.

• V-Port Ball Valve: Allows for precise ball valve flow control.

• Trunnion Ball Valve: Designed for high-pressure applications.

Comparison with Other Shut Off Valves

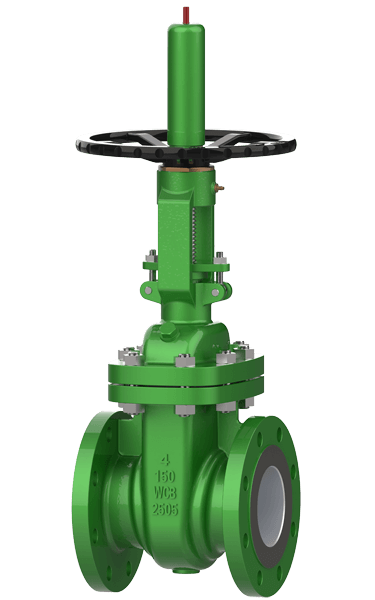

Gate Valves

Gate valves use a wedge-shaped gate to control flow. They are ideal for full-flow applications but are slower to operate and prone to corrosion over time.

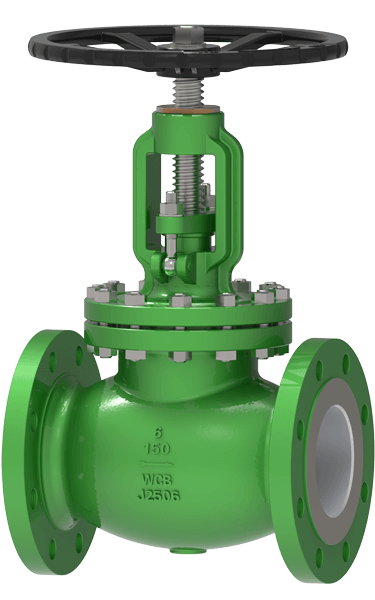

Globe Valves

Globe valves regulate flow using a plug and seat. They are excellent for throttling but are less efficient for full shut-off compared to a ball shut off valve.

Butterfly Valves

Butterfly valves employ a disc mounted on a rotating shaft. While cost-effective for large diameters, they may not offer the same leak-proof performance as ball valve water shut off systems.

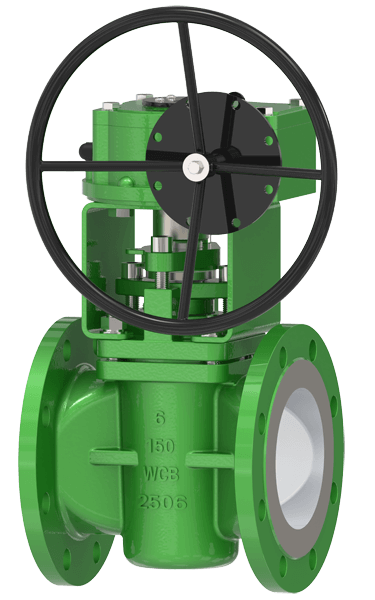

Plug Valves

A plug valve is a fundamental type of quarter-turn rotary valve used primarily for on/off isolation of fluid flow. Its simple yet effective design consists of a cylindrical or conical plug housed within the valve body. This plug has a hollow passage through its center.

Ball Valve Applications

Ball Valve Water Shut Off

Ball valve water shut off systems are common in residential and commercial plumbing due to their reliability and longevity.

Automatic Shut Off Valve Uses

Automatic shut off valve systems, often integrated with sensors, are used in industrial settings for emergency shutdowns or irrigation systems for water conservation.

Ball Valve Flow Control

While primarily designed for on/off applications, certain ball valve types like V-port valves allow for moderate flow regulation.

Manual vs Automatic Ball Valve Flow Control

Manual valves require physical operation, while automated valves use actuators for remote or programmed control.

Benefits of Ball Shut Off Valves

• Long Service Life: Resistant to wear and corrosion.

• Low Maintenance: Simple design reduces upkeep needs.

• High Pressure Tolerance: Suitable for industrial applications.

• Easy Installation: Available in sizes like 1 2 inch shut off ball valve.

Maintenance of Ball Valves

Best Practices for Ball Valve Maintenance

• Regularly operate the valve to prevent seizing.

• Check for leaks around the stem and seals.

• Lubricate the valve when necessary.

Common Issues and Solutions

• Stiff Handle: Often caused by debris—disassemble and clean.

• Leaks: Replace seals or the entire valve if damaged.

Conclusion

When selecting a shut off valve-ball valve options offer unparalleled durability, ease of use, and versatility. While other valves like gate, globe, or butterfly may suit specific needs, ball valves remain the top choice for most residential and industrial applications. Assess your system’s requirements to make the best decision.

Post time: Aug-27-2025