In the world of industrial fluid control, where corrosion, high pressure, and extreme temperatures are the norm, standard stainless steel valves can fall short. For applications where failure is not an option, industry leaders turn to Quality Super Stainless Steel Plug Valves. These valves represent the pinnacle of material science and engineering, offering unparalleled performance and longevity. At NSW Valve, as a dedicated quality super stainless steel plug valves manufacturer, we engineer these robust valves to meet the most stringent operational challenges.

Understanding the Composition of Super Stainless Steel

The term “super stainless steel” refers to a group of advanced alloys designed to outperform common 300-series stainless steels (like 304 or 316). Their superior properties stem from a carefully balanced composition centered around high levels of nickel, chromium, and molybdenum.

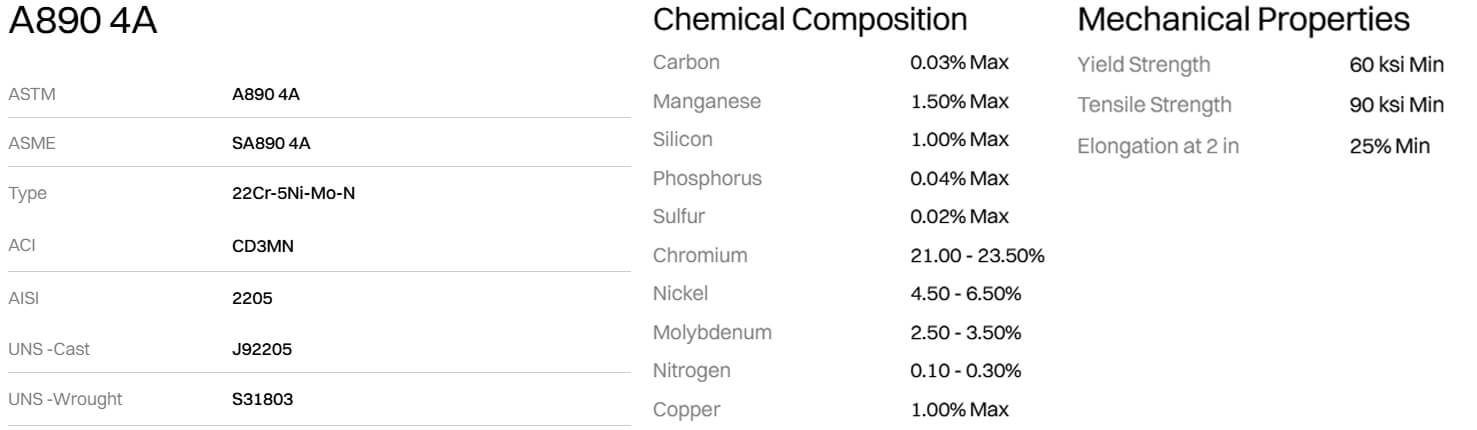

Super Stainless Steel: A890 4A, 2205, S31803

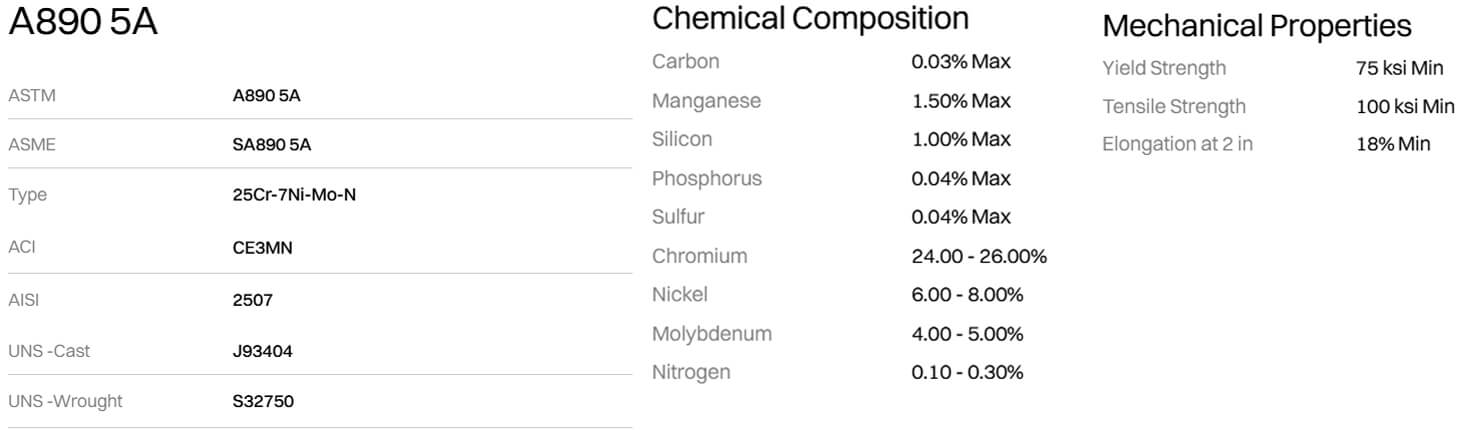

Super Stainless Steel: A890 5A, 2507, S32750

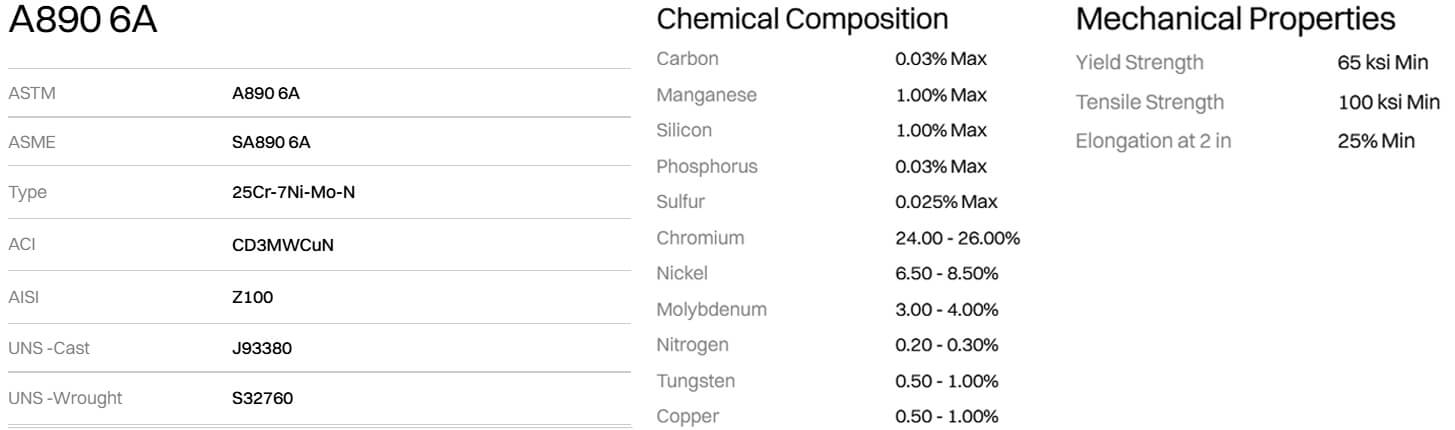

Super Stainless Steel: A890 6A, Z100, S32760

Super Martensitic Stainless Steel

This grade features a tempered martensitic base structure with a high chromium content (typically around 16%) and may contain 10% to 40% retained austenite. A typical composition includes Carbon (C) ≤0.08%, Chromium (Cr) 16%~18%, and Nickel (Ni) 8%~12%. This combination offers high strength and improved corrosion resistance over conventional martensitic steels.

Super Austenitic Stainless Steel

Characterized by a primarily austenitic structure, these alloys contain approximately 24%~26% Chromium, 6%~8% Nickel, and 3%~3.7% Molybdenum. Nitrogen (N) is added (0.24%~0.32%) for solid solution strengthening. Crucially, carbon content is strictly controlled at ≤0.03% to minimize the risk of intergranular corrosion.

General Composition Characteristics

Most super stainless steels contain Molybdenum (Mo) to dramatically enhance resistance to pitting and crevice corrosion, especially in chloride-rich environments. Nickel increases toughness and ductility, while Chromium forms a dense, protective passive oxide layer on the surface. Elements like Manganese (Mn) and Silicon (Si) are adjusted to optimize casting and manufacturing processes.

Key Advantages of Using Super Stainless Steel Plug Valves

The marriage of super stainless steel materials with the plug valve design creates a component of exceptional reliability and performance.

Corrosion Resistance and High-Temperature Suitability

The high Nickel, Chromium, and Molybdenum content provides far greater corrosion resistance and thermal stability than standard stainless steels. Quality super stainless steel plug valves can operate long-term in aggressive environments with strong acids, alkalis, and chlorides, with maximum service temperatures reaching up to 325°C and beyond for specific grades.

Sealing Performance and Zero-Leakage Assurance

Our plug valves feature a precision design, often with a dual-sealing groove ring structure. As the plug rotates, it gradually generates sufficient specific pressure to achieve a bubble-tight, zero-leakage seal in both the fully open and fully closed positions. The wiping action between the PTFE sleeve and the plug cleans the sealing surfaces and extends service life, with sealing effectiveness being independent of line pressure.

Lightweight Structure and Operational Flexibility

With a straightforward full-port, straight-through or three-way design, these valves are compact and lightweight, making them ideal for frequent operation. A simple 90-degree rotation is all that’s needed to open or close the valve, facilitating easy automation and remote control while keeping maintenance costs low.

Durability and Long Service Life in Harsh Environments

The true value of a super stainless steel plug valve is proven under extreme conditions.

Corrosion Resistance

Super austenitic alloys (e.g., UB6, 904L, 254SMO, AL-6XN) exhibit exceptional resistance to a vast range of corrosive media, enabling stable operation in environments with a pH from 0 to 14. This effectively prevents structural degradation caused by chemical attack.

High-Temperature and High-Pressure Resistance

These valves are built to withstand extreme service conditions, handling temperatures up to 400°C and pressure ratings up to 16MPa. NSW Valve’s products, for instance, are designed for a temperature range of -40°C to 400°C and meet pressure differential requirements of 1.0-2.5MPa and higher, making them suitable for petrochemical and power generation applications.

Mechanical Performance and Sealing Integrity

Super stainless steels offer an excellent combination of high strength and toughness, ensuring the valve body and internal components resist deformation under high pressure and flow shock. The robust sealing design guarantees leak-tight operation even after prolonged cycling, complying with stringent standards like API 607.

Cost-Effectiveness: A Long-Term Investment

While the initial investment in a quality super stainless steel plug valve may be higher than a standard valve, it is a strategic long-term investment. The dramatically extended service life, reduced frequency of replacement, and minimal maintenance requirements lead to significantly lower total cost of ownership (TCO). Preventing unplanned downtime, production losses, or environmental incidents due to valve failure offers immense financial and operational benefits.

Industrial Applications of Super Stainless Steel Plug Valves

These valves are the preferred choice across industries where performance is critical.

Petrochemical Industry

Used in oil field extraction, transmission, and refining equipment—such as wellhead devices, transfer pipelines, and inlet/outlet controls on crude oil storage tanks. Their high-pressure capability (above 10MPa) and corrosion resistance handle sulfides and other aggressive compounds in crude oil.

Natural Gas Transmission

Essential for flow control in long-distance pipelines, pressure regulating stations, and compressor stations, where they must withstand pressures above 20MPa. Materials are often nickel-based alloys or super stainless steels to resist hydrogen embrittlement, featuring anti-static and superior sealing designs.

Corrosive Chemical Media Control

Ideal for handling pipelines containing acid/alkali solutions, strong oxidizers (e.g., nitric acid), or organic solvents. Wetted parts, often lined with PTFE or made from alloys like Hastelloy, provide the necessary corrosion resistance alongside safety features like fire-safe design.

Cryogenic Media Control

Suitable for liquefied gas applications like LNG (liquefied natural gas, down to -162°C) at storage tank inlets/outlets and loading terminals. Valve bodies are crafted from specially treated stainless steels for low-temperature service, with seals made from materials like EPDM rubber.

Comparison: Super Stainless Plug Valves vs. Other Valve Types

Super Stainless Steel Plug Valve Vs. Ball Valve

• Sealing Structure & Reliability: Plug valves use a tapered plug design that offers a larger sealing surface area and a wedging action. This often results in a more reliable, bubble-tight seal compared to the line contact of a ball valve’s seats, especially in applications with abrasive particles or frequent cycling that can erode ball valve seats.

• Operating Torque: A ball valve typically has lower operating torque, especially when quarter-turn. However, a properly lubricated plug valve operates smoothly.

• Suitability: While ball valves excel in on/off service for clean fluids, super stainless steel plug valves are often superior for handling slurries, viscous fluids, and abrasive media due to their wiping action and more robust sealing.

Super Stainless Steel Plug Valve Vs. Gate Valve

The comparison between super stainless steel plug valves and gate valves primarily focuses on their structural characteristics, applicable applications, and performance differences:

• Structure and Operating Principle

Plug valves open and close by rotating the plug 90 degrees. Their sealing surface relies on direct contact between the plug and the valve seat, but super stainless steel improves sealing performance. Gate valves, on the other hand, open and close by raising and lowering the gate disc. Their seal relies on friction between the disc and the valve seat, and prolonged partial opening can easily lead to wear.

• Applicable Pressure and Temperature

Super stainless steel plug valves are suitable for low to medium pressure applications (typically ≤ 1.6 MPa). Because their seal relies on direct contact, they are prone to leakage at high pressures. Gate valves, on the other hand, can withstand high to ultra-high pressures (such as petrochemical hydrogenation units) and achieve reliable sealing through media pressure distribution.

• Media Compatibility

Plug valves are more suitable for clean, low-viscosity media (such as water and air). Media containing particles or high viscosity can easily cause sticking. Gate valves are suitable for a wide range of media (including mildly corrosive chemicals) and are particularly suitable for applications requiring fluid shutoff.

• Operation and Maintenance

Plug valves have low opening and closing torque and are frictionless, making them easy to maintain (impurities can be quickly removed). The gate valve has a large operating torque, and the sealing surface is easily worn out after long-term use. The medium containing impurities may cause leakage.

Material & Corrosion Resistance

The core differentiator is the material. A Super Stainless Steel Plug Valve utilizes advanced alloys (e.g., duplex, super duplex, super austenitic) that offer far greater resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) than a standard Stainless Steel Ball Valve made from 316SS, particularly in high-chloride environments.

Maintenance Tips for Optimal Performance

Maximize the lifespan of your valves with proper care.

Seal Maintenance

Periodically inspect the plug and body seal surfaces for wear or corrosion. Clean thoroughly to remove any built-up debris that could compromise the seal.

Lubrication Management

For lubricated plug valves, maintain proper lubrication by injecting a compatible high-performance grease (like EL-80) as recommended to ensure smooth operation and protect sealing surfaces.

Operational Guidelines

Operate the valve smoothly and evenly through its 90-degree turn. Avoid jarring impacts or excessive force. If operation becomes difficult, investigate the cause rather than forcing it.

Regular Inspection

Implement a routine inspection schedule. Monthly checks for external leaks and corrosion are advised. Quarterly, more thorough inspections of the actuator (if present) and lubrication system should be performed.

Choosing the Right Quality Valve Supplier

Selecting a partner goes beyond purchasing a product. Choose a quality super stainless steel plug valves supplier and factory like NSW Valve that offers:

• In-House Manufacturing: Control over the entire production process, from material selection to machining.

• Material Traceability: Certified mill test reports (MTRs) guaranteeing alloy composition.

• Technical Expertise: Engineering support to help you select the right valve and material for your specific application.

• Quality Certifications: Adherence to international standards (API, ASME, ISO).

• After-Sales Support: Reliable customer service and availability of spare parts.

Choose Super Stainless Steel Plug Valves

Material: ASTM A890 4A, ASTM A890 5A, ASTM A890 6A, ASTM A890 5A, UNS S32550, S32750, S32760, 2205, 2507, Z100

Dimensions: NPS: 1/2, 3/4, 1, 1 1/2, 2, 2 1/2, 3, 4, 5, 6, 8, 10, 12, 14, 16, 18, 20, 24, 28, 32, 36, 40 Inch.

Pressure Range: Class 150lb, 300lb, 600lb, 900lb, 1500lb, 2500lb, etc.

Connection: Flange RF, Flange RTJ, Flange FF, Thread, Butted Weld, Socket Weld, etc.

Actuation: Handwheel, Pneumatic Actuator, or Electric Actuator.

Certifications: API 6D, API 599, ASME B16.34, API 607, ISO 15848-1, ISO 15848-2.

Global Quality Super Stainless Steel Plug Valves Manufacturer

Emerson (Fisher)

Fisher is a globally renowned valve brand, offering a wide range of plug valves widely used in the oil, gas, and chemical industries, renowned for its high quality and reliability.

ROUTH

ROUTH is a leading global valve supplier, providing high-efficiency plug valves, particularly suitable for the oil, gas, and wastewater treatment industries, with excellent corrosion resistance and high-temperature performance.

Swagelok

Swagelok is a professional valve supplier in the United States, offering high-quality plug valves for precision fluid control, widely used in the oil, gas, chemical, and laboratory industries.

NSW is a professional valve supplier and manufacturer in China. We offer high-quality super stainless steel plug valves, ball valves, gate valves, butterfly valves, and other products. Our products are widely used in the oil, gas, LNG, power generation, and marine industries.

ROBERTSON (USA)

ROBERTSON, a valve manufacturer, offers a wide range of plug valves widely used in high-temperature and high-pressure environments, including those in the chemical, oil, and power industries.

Conclusion: Invest in Quality for Industrial Success

In critical industrial processes, component failure is not an option. Choosing quality super stainless steel plug valves from a reputable manufacturer like NSW Valve is an investment in safety, reliability, and operational efficiency. By understanding their superior materials, advantages, and ideal applications, you can make an informed decision that ensures long-term performance and protects your valuable assets. Partner with a supplier who provides not just a product, but a engineering solution built to last.

Ready to specify the right valve for your challenging application? Contact NSW Valve’s experts today to discuss your requirements.

Post time: Sep-09-2025