Monel K500 vs Monel 400: Choosing the Right Nickel-Copper Alloy for Demanding Valve Applications

Selecting the optimal Monel alloy is critical for performance and longevity in harsh environments like marine engineering, oil & gas, and chemical processing. While both Monel 400 and Monel K500 are renowned nickel-copper alloys offering exceptional corrosion resistance, their distinct compositions and properties make them suited for different challenges. Choosing incorrectly can lead to premature failure or unnecessary cost. This guide provides an in-depth comparison and practical selection advice for engineers, with a focus on Monel Valve applications.

1. Core Differences: Composition & Strengthening

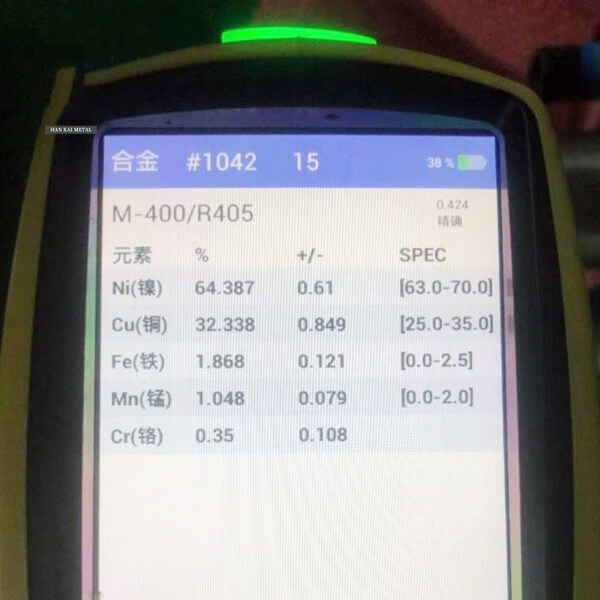

Chemical Composition (ASTM Standard)

| Element | Monel 400 | Monel K500 |

|---|---|---|

| Nickel (Ni) | 63-70% | 63-70% |

| Copper (Cu) | 28-34% | 27-33% |

| Aluminum (Al) | - | 2.3-3.15% |

| Titanium (Ti) | - | 0.35-0.85% |

| Iron (Fe) | ≤ 2.5% | ≤ 2.0% |

Key Takeaways:

Monel K500 contains deliberate additions of Aluminum (Al) and Titanium (Ti). This enables age-hardening (precipitation of γ’ phase), significantly boosting its strength.

Monel 400 relies solely on solid-solution strengthening. Its slightly higher copper content enhances resistance in specific reducing acid environments.

Both maintain the fundamental Ni-Cu matrix responsible for outstanding corrosion resistance.

2. Mechanical Properties & Corrosion Resistance

2.1 Mechanical Properties (Annealed / Aged)

| Property | Monel 400 (Annealed) | Monel K500 (Aged) |

|---|---|---|

| Tensile Strength (MPa) | 480-620 | 960-1200 |

| Yield Strength (MPa) | 170-340 | 650-900 |

| Elongation (%) | 35-45 | 20-30 |

| Hardness (HRB) | 65-85 | 25-35 (Pre-Age) → 35-45 (Aged) |

Conclusion:

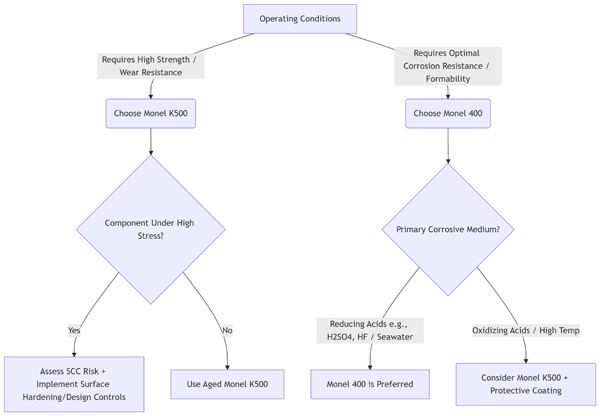

Need High Strength? Choose Monel K500 (strength is over 2x Monel 400). Ideal for high-pressure valve stems (Monel Valve stems, Monel Gate Valve stems/seats, Monel Ball Valve trunnions) and shafts.

Need High Formability? Choose Monel 400. Its superior ductility is better for components requiring deep drawing or cold forming.

2.2 Corrosion Resistance

| Corrosion Type | Monel 400 Performance | Monel K500 Performance |

|---|---|---|

| Seawater Corrosion | Excellent (proven over decades) | Very Good (but susceptible to SCC in high-stress areas) |

| Acidic Environments (e.g., Sulfuric, HF) | Superior (best choice for reducing acids) | Good (Al/Ti additions slightly increase pitting risk) |

| High-Temperature Oxidation | Stable up to 480°C (900°F) | Stable up to 540°C (1000°F) (Al improves oxidation resistance) |

| Stress Corrosion Cracking (SCC) | Highly Resistant (rarely occurs) | Susceptible (caution needed in high-stress + halogen environments) |

Note: In 3.5% NaCl solution at 50°C, Monel K500′s SCC threshold is approximately 30% lower than Monel 400′s.

3. Manufacturing & Processing Differences

3.1 Fabrication

| Process | Monel 400 | Monel K500 |

|---|---|---|

| Forging Temp | 870-1175°C (1600-2150°F) | 980-1200°C (1800-2200°F) (narrower window) |

| Hot Working | Relatively Easy | Requires strict control (finish temp critical) |

| Weldability | Excellent (TIG, MIG, Brazing) | Poorer (requires post-weld aging for full strength) |

3.2 Heat Treatment

Monel 400: Typically requires only annealing (870°C / Water Quench) for softening.

Monel K500: Must undergo age-hardening (595°C / 16h or 760°C / 4h) to achieve its peak strength. This is critical for high-performance Monel Butterfly Valve shafts or Monel Ball Valve components.

4. Valve Application Showcase: Matching Alloy to Service

4.1 Monel 400: The Corrosion Champion

Seawater Systems: Pumps, Monel Gate Valves, piping, heat exchangers. Its supreme seawater resistance is legendary.

Chemical Processing: Sulfuric acid/Hydrofluoric Acid (HF) storage tanks, distillation columns. The top choice for harsh, reducing acids.

Low-Stress Corrosion Components: Marine fasteners, platform railings, valve bodies where extreme strength isn’t paramount.

4.2 Monel K500: The High-Strength Specialist

High-Strength Corrosion Components: Ship propeller shafts, oil drill collars, high-pressure Monel Valve stems and trim.

Wear Resistance: Ideal for Monel Ball Valve stems, Monel Gate Valve wedges/stems, bearing sleeves (Aged hardness ~HRC 35).

High-Temp/High-Pressure Fasteners: Aerospace engine bolts, critical Monel Valve bolting subjected to vibration.

5. Choosing the Right Monel Valve Alloy: A Decision Guide

Monel Valve FAQs

Q1: Can Monel K500 completely replace Monel 400 in valves?

A: No. For critical service in hydrofluoric acid (HF) or hot, concentrated sulfuric acid, Monel 400 Valve components offer superior, proven corrosion resistance that K500 cannot match.

Q2: Does welding a Monel K500 Valve require re-aging?

A: Absolutely. The heat-affected zone (HAZ) loses over 40% of its strength after welding. Post-weld aging (typically 760°C / 4h) is mandatory to restore properties in welded Monel K500 Valve assemblies.

Q3: How can I prevent Stress Corrosion Cracking (SCC) in Monel K500 Valve parts?

A: Follow these key principles for Monel K500 Valve stems, shafts, and high-stress components:

Design Stress: Keep operational stresses ≤ 30% of the alloy’s yield strength.

Surface Treatment: Implement shot peening or nitriding for compressive surface stresses.

Contaminant Avoidance: Strictly prevent contact with mercury (Hg) or molten metals.

Conclusion: The Right Tool for the Job

Think of Monel 400 and Monel K500 as the elite specialists within the nickel-copper alloy family. Monel 400 is the versatile corrosion warrior, excelling where aggressive chemicals and seawater dominate. Monel K500 is the high-strength specialist, delivering unmatched performance under load, at elevated temperatures, or where wear resistance is critical – making it ideal for demanding Monel Gate Valve, Monel Butterfly Valve, and Monel Ball Valve applications.

Understanding the distinct performance boundaries of Monel 400 vs. K500 is essential. By matching the alloy’s core strengths – whether it’s the supreme corrosion resistance of 400 or the enhanced strength of K500 – to your specific valve application and environmental demands, you ensure optimal performance, safety, and cost-effectiveness in the most challenging industrial and marine environments. Choose wisely!

Post time: Aug-18-2025