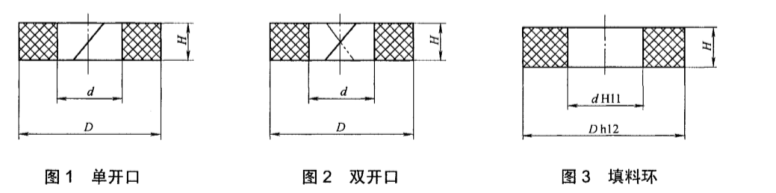

1. Graphite Packing type description

There are the following 3 types of fillers commonly used in valves

The packing used in this project is the single-opening type in Figure 1 and the ring-shaped packing in Figure 3. The actual photos are as follows:

Figure 1 Single-opening type packing

Figure 3 Packing ring packing

The use functions of the above two packings are the same, the difference lies in the different usage scenarios. The single-opening packing is suitable for replacing the packing during daily valve maintenance. Packing can be replaced online, and the packing ring packing is suitable for overhauling the valve. Used for disassembly and maintenance.

2. Description of graphite packing characteristics

According to the technical requirements of the filler manufacturing, the filler needs to have a certain resilience rate, so there will be a resilience from the inside to the outside after the filling is formed. The above-mentioned two kinds of single-opening type graphite fillers are braided fillers whose molding process is braided by multiple graphite fibers, and the resilience is absorbed by the braided gap and there is no obvious trace of longing for expansion. Packing ring-type packing graphite is a compact packing with a relatively compact interior. After a long time of standing, the internal resilience will show cracks on the surface of the packing and release this part of the stress. This type of filler will remain stable and not change after a certain crack is generated. When it is compressed again, the crack disappears and the rebound rate meets the requirement.

The following are the technical requirements for flexible graphite rings

Table 2 Packing ring performance

|

performance |

unit |

index |

||

|

Single flexible graphite |

Metal composite |

|||

|

seal |

g/cm³ |

1.4~1.7 |

≥1.7 |

|

|

Compression ratio |

% |

10~25 |

7~20 |

|

|

Rebound rate |

% |

≥35 |

≥35 |

|

|

Thermal weight loss a |

450℃ |

% |

≤0.8 |

—- |

|

600℃ |

% |

≤8.0 |

≤6.0 |

|

|

Coefficient of friction |

—- |

≤0.14 |

≤0.14 |

|

|

a For metal composites, when the melting point of the metal is lower than the test temperature, this temperature test is not suitable. |

||||

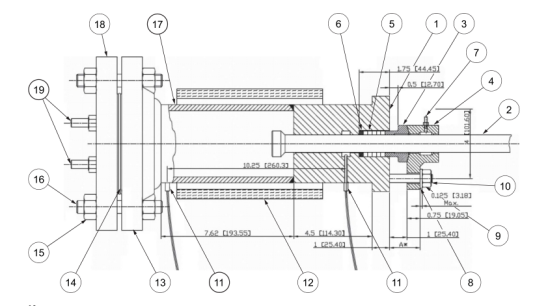

3. About the use of graphite packing

The graphite packing is used in the sealed space between the valve stem and the packing gland, and the packing is in a compressed state during operation. Whether it is a single-opening type packing or a packing ring type packing, there is no difference in the function of the compressed state.

The following is a diagram of the working state of the packing (illustration of the packing seal test)

Post time: Jul-12-2021