To understand how to repair a gate valve, we must first know what a gate valve is and learn its main components and working principles. This knowledge helps identify why a gate valve fails to function properly, enabling targeted repairs.

What is a Gate Valve?

A gate valve (Gate Valve) uses a gate as its closing element. The gate moves perpendicular to the fluid direction and can only be fully opened or closed—it cannot regulate or throttle flow. In pipelines, gate valves primarily cut off media flow. They allow bidirectional flow, feature easy installation, convenient operation, smooth channels, low flow resistance, and simple structure.

Main Components of a Gate Valve

A gate valve controls fluid flow by vertically raising/lowering its gate. Core components include:

• Valve Body: Connects to pipes and withstands medium pressure. Typically made of cast iron, cast steel, or stainless steel.

• Bonnet: Bolted to the valve body to form a sealed cavity.

• Gate: The vertically moving closure element, available in wedge-type or parallel-slide designs.

• Stem: Connects the gate to the actuator, transmitting lifting torque.

• Sealing Surface: Contact area between the gate and seat, often hardfaced with alloys (e.g., STL) for wear resistance.

• Actuator: Manual, electric, pneumatic, or hydraulic device that controls gate movement.

How a Gate Valve Works

Rotating the handwheel or actuator drives the stem to lift/lower the gate vertically:

• Open State: Gate retracts above the valve passage, allowing unobstructed flow.

• Closed State: Gate descends onto the seat seal, blocking fluid.

• Flow Control: Some gate valves allow partial opening for limited flow regulation (low precision).

Common Gate Valve Issues

1. Leakage Problems

Symptoms:

Leaks around valve joints, seat/gate surfaces, etc. Causes include worn/damaged seals, deformed gaskets, or loose connections.

Solutions:

• Replace damaged seals/gaskets.

• Tighten loose connections.

• Inspect seal ring dimensions and flange groove surfaces; repair or replace if needed.

• Clean sealing surfaces to remove debris.

2. Gate Valve Jamming

Symptoms:

Valve fails to open/close due to debris buildup, rusted/bent stems, or excessive tightness.

Solutions:

• Clean debris between gate and seat.

• Repair or replace bent/rusted stems.

• Adjust gate-seat tightness for smooth operation.

3. How to Fix a Gate Valve That Doesn’t Close

Symptoms:

Failure to fully close caused by stuck stems/balls, pipeline congestion, or excessive gate-seat clearance.

Solutions:

• Disassemble and clean stem deposits after closing the valve.

• Adjust gate-seat clearance.

• Clear obstructions around pipes for unrestricted operation.

4. Noise Issues

Symptoms:

Operational noise from air/fluid vibration, excessive friction, or uneven sealing surfaces.

Solutions:

• Eliminate vibration sources; optimize valve-pipe connections.

• Replace uneven sealing surfaces.

• Lubricate contact points to reduce friction.

5. Unresponsive Operation

Symptoms:

Stiff movement due to inadequate lubrication, bent stems, or improper installation.

Solutions:

• Apply lubricant to the stem and seat.

• Repair/replace bent stems.

• Reinstall the valve correctly.

6. Other Failures & Solutions

• Body Leaks: Repair/replace valve bodies with casting defects (e.g., sand holes).

• Packing Leaks: Tighten packing glands; replace damaged stems/packing.

• Stiff Handwheel: Clean dirt/sand; replace corroded parts; lubricate regularly.

Regular maintenance prevents most gate valve failures. For industrial machinery, timely upkeep ensures long-term stability.

How to Disassemble a Gate Valve for Repair

1. Valve Disassembly

Initial Cleaning & Marking:

Clean dirt with brushes/rags. Prepare tools and mark V-shapes on the bonnet-body joint for reassembly alignment.

Gland Nut & Bonnet Nut Handling:

Remove nuts systematically to avoid confusion. Store removed nuts/washers orderly.

Handwheel & Edge Processing:

Remove the handwheel after opening the valve slightly. Smooth edges with a file to prevent damage.

Further Disassembly & Inspection:

Remove bonnet nuts and gland followers. Inspect sealing lines. Retract the stem and remove packing.

Stem & Seal Inspection:

Polish the stem with sandpaper, measure straightness (<0.2mm), and check thread integrity.

Seat & Gland Check:

Inspect seat-bonnet contact surfaces and threads for damage. Ensure no cracks/sand holes exist.

2. Documentation & Repair

Records:

Document deviations (e.g., stem straightness, seat condition).

Repair Summary:

Note if stem-gland clearance fails standards; record other compliant parts.

Sign-off:

Include inspector names and date for traceability.

3. Reassembly

Packing & Gland Reinstallation:

Repack the stuffing box. Mount the gland with the stem half-open.

Component Installation & Cleaning:

Reattach parts sequentially (e.g., handwheel). Adjust gland-stem alignment. Clean surfaces before closure.

FAQs: Gate Valve Selection & Applications

1. Does a gate valve have flow direction requirements?

No, Gate valves are bidirectional by design.

Their symmetrical structure allows fluid to pass equally well from either direction. However, for maintenance convenience, install with the stem vertical (handwheel upward) to prevent debris accumulation in the bonnet cavity.

2. Gate valve vs Ball valve: Which is better?

| Feature | Gate Valve | Ball Valve |

|---|---|---|

| Sealing | Metal-to-metal seals | Soft/hard seals |

| Flow Path | Full-bore (low pressure drop) | Full-bore |

| Operation | Slow open/close | Quarter-turn quick operation |

| Pressure | High-pressure suitable | Medium pressure |

| Repairability | Field-repairable components | Limited repairability |

| Best for: Gate valves – high-pressure steam/oil pipelines; Ball valves – frequent operation in water/gas lines. | ||

3. Gate valve vs Butterfly valve: Which to choose?

| Criterion | Gate Valve | Butterfly Valve |

|---|---|---|

| Space | Requires more length | Compact design |

| Pressure Loss | Minimal (<5% of DP) | Significant (10-30% DP) |

| Cost | Higher (large sizes) | Lower |

| Sealing | Zero leakage possible | Minor seepage common |

| Best for: Gate valves – zero-leakage critical systems; Butterfly valves – space-limited low-pressure water systems. | ||

4. Gate valve vs Globe valve: Differences

• Flow Control: Globe valves excel at throttling; gate valves should not be used for flow regulation (causes seat erosion).

• Pressure Drop: Globe valves create high resistance; gate valves offer near-zero resistance when fully open.

• Installation: Globe valves have directional flow arrows (must follow); gate valves are non-directional.

• Use gate valves for: Isolation in pump outlets, pipeline headers where low resistance is critical.

5. Gate valve vs Check valve: Can they interchange?

No, Check valves are automatic (prevent backflow without manual operation), while gate valves require manual/actuated control.

Gate valves cannot prevent reverse flow – if backflow protection is needed, install a check valve downstream of the gate valve.

6. Plumbing Pipe vs Industrial Pipe: Which suits gate valves best?

| Application | Plumbing Pipe | Industrial Pipe |

|---|---|---|

| Valve Size | Small (½”-2″) | Large (2″-48″+) |

| Material | Bronze/brass | Cast steel/stainless |

| Pressure | Low (<150 PSI) | High (>300 PSI) |

| Use Case | Main water shutoff | Oil/gas/steam isolation |

| Conclusion: Gate valves are ideal for industrial pipes due to robust construction and high-pressure tolerance. For residential plumbing, ball valves are often preferred for quicker operation. | ||

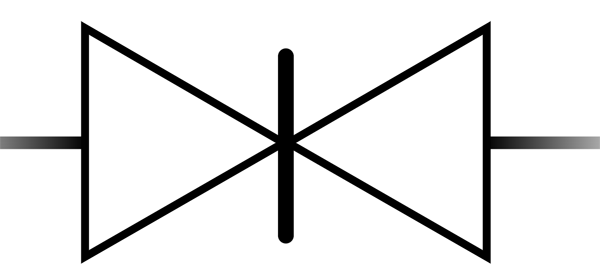

7. What is the Symbol of Gate Valves in P&IDs (Piping & Instrumentation Diagrams)

In engineering drawings or flow charts, gate valves are often represented by two opposing triangles (▷ι◁), with a vertical line in the middle symbolizing the lifting and lowering movement of the valve plate, which intuitively reflects the opening and closing principle of the gate valve. The specific diagram is as follows:

Conclusion

Most gate valve failures can be avoided or resolved through inspection, maintenance, and proper operation. Regular checks ensure optimal performance. Avoid excessive force during use to prevent damage. Scientific maintenance extends service life and improves pipeline efficiency.

Post time: Jul-30-2025