What is a Gate Valve

A gate valve controls fluid flow by vertically raising or lowering a gate (wedge). Designed for full open/close operations – not flow regulation – it offers minimal flow resistance and superior sealing. Widely used in oil/gas, chemical plants, and power generation, its reliability makes it critical for backup systems.

Gate Valve Working Principle

The gate moves perpendicular to fluid flow. When fully raised, it allows unrestricted flow; when lowered, it creates a tight seal against valve seats. Never partially open gate valves – this causes seal erosion and vibration damage.

5 Critical Steps for Storing Gate Valves

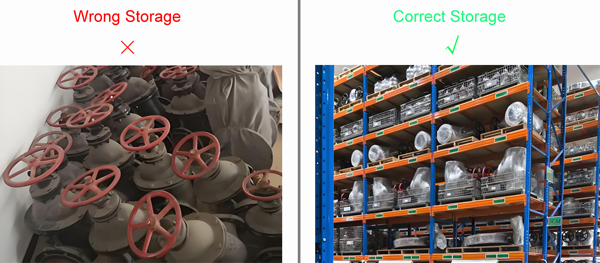

Proper storage prevents corrosion and ensures backup valves function when needed.

1. Ideal Storage Environment

– Indoor & Dry: Store in sealed, low-humidity areas (<60% RH).

– Avoid Corrosives: Keep away from chemicals, salt, or acidic fumes.

– Temperature Control: Maintain 5°C–40°C (41°F–104°F). (Refer to ISO 5208 standard: Excessive humidity can easily lead to rust of metal parts and aging of rubber seals.)

- Large and small valves should be stored separately: Small valves can be placed on shelves, and large valves should be arranged neatly on the floor of the warehouse, while ensuring that the flange connection surface does not touch the ground.

- Storing valves outdoors: Must be sure to cover them with rainproof and dustproof items, such as tarpaulin, linoleum, etc. (If conditions permit, it is recommended not to store them outdoors)

Tips: Store the gate valve indoors and keep the room dry and ventilated.

2. Valve Preparation

– Close the Gate: Prevents dust ingress.

– Seal Ports: Use PVC caps or wax-coated plugs on flanges.

– Lubricate Stems: Apply high-quality grease on exposed stems.

Tips: Both ends of the passage must be sealed with wax paper or plastic sheets to prevent dirt from entering.

3. Long-Term Storage Protocol

– Quarterly Inspections: Check for rust, cap integrity, and lubrication.

– Rotate Handwheels: Turn 90° every 3 months to prevent seizing.

– Documentation: Tag valves with storage date and inspection logs.

- Anti-rust treatment:

1. Metal valves (such as gate valves and stop valves) need to be coated with anti-rust oil or grease, especially flange surfaces, threaded joints and other easily oxidized parts.

2. When stored for a long time (more than 6 months), it is recommended to check and add anti-rust agent per 3 months (according to API 598 standard).

4. Separate Stainless and Carbon Steel Gate Valve

- Galvanic Corrosion Risk:

1. Contact + moisture creates an electrochemical cell.

2. Carbon steel becomes the anode, corroding rapidly.

3. Stainless steel (the cathode) has its protective passive layer damaged, accelerating future corrosion.

- Carbon Migration (Carburization):

1. Direct contact allows carbon atoms to move from carbon steel into stainless steel.

2. This disrupts the stainless steel’s structure, drastically reducing its corrosion resistance.

- Storage Best Practices:

1. Separate Storage: Always store in distinct areas.

2. Minimum Distance: Maintain at least 50 cm (20 inches) separation, especially in humid environments.

3. Temporary Contact: Use dry, non-conductive barriers (wood, plastic, rubber) or protective wraps.

5. Essential Rules for Valve Storage Optimization

- Color-Coding Identification

• Stainless steel valves → Blue tape

• Carbon steel valves → Yellow tape

Prevents visual management errors and galvanic corrosion.

- FIFO Warehouse Zoning

• Dedicated storage areas enable First-In-First-Out rotation

• Eliminates stock obsolescence (critical for backup valves)

- Cost-Protection Segregation

• Isolate stainless steel valves (cost 3-5x more)

• Prevents accidental misuse and corrosion damage

- Engineering Implementation

• Method Specification

• Partition Racking ≥500mm aisle spacing

• Electrochemical Isolation 8-10mm non-conductive rubber pads

*Compliance: Meets GB/T 20878-2017 standards.*

Critical Pro Tips

• Laser-etch material grades (e.g., “WCB”) on valve bodies

• Maintain <45% RH in storage areas

• Store backup gate valves upright – horizontal stacking compromises emergency sealing

Comparison of Backup Gate Valve Storage Methods

Gate Valve Maintenance: 4 Key Procedures

1. Routine Operational Care

– Lubricate Threads: Apply molybdenum disulfide paste to stem nuts quarterly.

– Clean Exteriors: Wipe dirt/debris monthly with non-abrasive cloths.

– Check Handwheels: Tighten loose bolts immediately to avoid misalignment.

2. Packing/Gland Maintenance

– Inspect Quarterly: Look for leaks around the stem.

– Adjust Gland Nuts: Tighten incrementally if weeping occurs – do not over-compress.

– Replace Packing: Use graphite-impregnated rope every 2–5 years.

3. Lubrication Best Practices

| Issue | Solution |

| Under-lubrication | Inject grease until it purges from seals |

| Over-lubrication | Stop when resistance increases (max 3,000 PSI) |

| Hardened Grease | Flush with kerosene before re-lubricating |

4. Transmission System Care

– Gearboxes: Change oil annually (ISO VG 220 recommended).

– Electric Actuators: Check moisture seals biannually.

– Manual Overrides: Cycle monthly to prevent seizure.

Special Tips for Backup Valves

– Pressure Relief: Open drain plugs before greasing to prevent seal blowout.

– Positioning: Store gate valves fully closed to keep seals engaged.

– Emergency Kits: Keep spare packing kits and gland nuts nearby.

Conclusion: Maximizing Valve Lifespan

Follow these rules for reliable backup gate valves:

1. Storage = Dry, sealed, and documented.

2. Maintenance = Scheduled lubrication and inspections.

3. Repairs = Address leaks immediately.

By prioritizing proactive care, you avoid 80% of valve failures – critical for emergency systems.

Post time: Jun-05-2025