What is a 3-way ball valve

A 3-way ball valve is a versatile fluid control device widely used in industrial, commercial, and residential systems. Its unique design enables flow diversion, mixing, or shut-off in pipelines. In this article, we’ll explore the working principles, types (including stainless steel 3-way ball valves, Y type, L type, and T type), applications, and advantages of these valves.

Working Principle of a 3-Way Ball Valve

A 3-way ball valve consists of a hollow, rotating ball with one or two ports (holes) and three pipe connections. By rotating the ball manually or via an actuator, the flow path is redirected. Depending on the valve’s design, it can:

- Divert flow between two outlets.

- Mix fluids from two inlets into one outlet.

- Shut off flow completely.

The ball’s position determines the flow direction. For example, a 90-degree turn might switch the flow from one port to another, while a 180-degree turn could block all flow.

Core Components of a 3-Way Ball Valve

Industrial 3-way ball valves rely on precision-engineered parts to control fluid flow. Understanding these components ensures optimal valve selection for applications like chemical processing, HVAC, and oil/gas systems.

1. Critical Functional Parts

• Ball (Flow Control Sphere)

Material: Stainless steel (304/316), brass, or titanium alloys

Design: Features L/T/Y-shaped bore channels for flow diversion/mixing

Surface Treatment: Mirror-polished (Ra≤0.8μm) for zero-leakage sealing

• Valve Seat (Primary Seal)

Material: PTFE (Teflon™), PEEK, or reinforced elastomers

Function: Creates metal-to-soft seal with ball at flow ports

Temp/Pressure Range: -50°C to 260°C | Up to PN40 (Class 300)

2. Sealing System

| Component | Role & Specifications | Common Materials |

|---|---|---|

Seal Rings |

Secondary leak prevention between ball & seats | NBR, EPDM, PTFE-encapsulated |

Stem |

Torque transmission from actuator to ball | 304 SS with chrome plating |

| - Anti-blowout design per API 608 standard | - Rotary friction ≤15 Nm |

3. Actuation & Structural Elements

• Handle/Actuator

Manual: 90° or 180° position indicators

Automated: Electric/pneumatic actuators (IP67 rated) with 4-20mA control

• Valve Body

Materials: Carbon steel (WCB), stainless steel (CF8M), ductile iron

Pressure Ratings: PN16 (1.6 MPa), PN25 (2.5 MPa), PN40 (4.0 MPa)

End Connections: Threaded (NPT/BSP), flanged (ASME B16.5), or welded

• Accessories

Position sensors, limit switches, or integrated check valves (optional)

4. Technical Insights for Engineers

• Material Selection Guide

Use 316L SS balls + PTFE seats for acids/alkalis; carbon steel bodies for steam lines (cost-savings ≥30%).

• Failure Prevention

High-temp applications: Specify graphite-infused seals (prevent extrusion at >200°C)

Abrasive fluids: Opt for hard-coated balls (HVOF tungsten carbide)

Types of 3 Way Ball Valves

Three-way ball valves are categorized based on their port configurations:

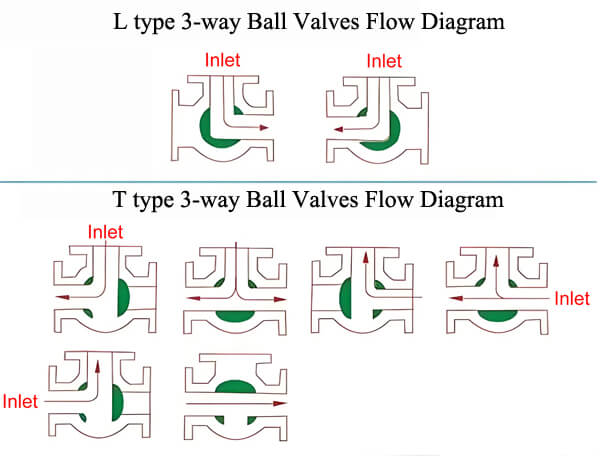

1. L-Type 3-Way Ball Valve

- The L-port valve has an “L”-shaped bore.

- It redirects flow between two ports while blocking the third.

- Applications: Ideal for flow switching (e.g., alternating between cooling and heating systems).

2. T-Type 3-Way Ball Valve

- The T-port valve features a “T”-shaped bore.

- It can mix two incoming flows or split one flow into two directions.

- Applications: Used in blending systems, such as combining hot and cold water.

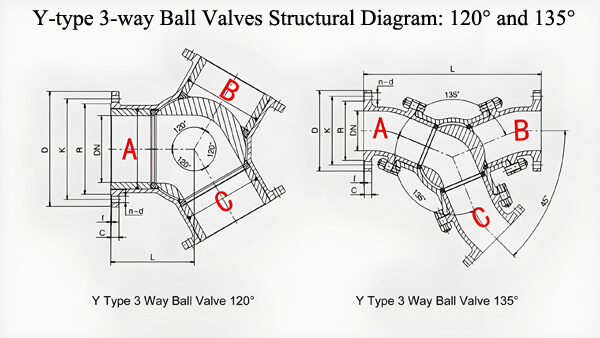

3. Y-Type 3-Way Ball Valve

- The Y-port valve has a 120-degree angled bore, minimizing pressure drop.

- Suited for applications requiring smooth flow diversion with minimal turbulence.

- Applications: Common in chemical processing and HVAC systems.

Additionally, stainless steel 3-way ball valves are popular for their corrosion resistance, making them ideal for harsh environments like marine or chemical industries.

How 3-Way Ball Valves Differ from Other Valve Types

Unlike conventional valves limited to on/off functions, 3-way ball valves enable complex flow control (diversion, mixing, switching) in a single compact unit. We analyze structural and performance distinctions using engineering data.

1. Unique Design Advantages

A. Multiport Flow Control

|

Valve Type |

Flow Path |

Capabilities |

|---|---|---|

|

3-Way Ball Valve |

L/T-shaped bore |

• Flow splitting (1 inlet → 2 outlets) • Flow mixing (2 inlets → 1 outlet) • Direction switching |

|

Standard Ball Valve |

Straight bore |

• On/off only |

|

Gate/Globe Valve |

Linear flow |

• Throttling or isolation |

*Example: T-port valves adjust flow ratios (e.g., 70/30 split) in blending systems.*

B. Space-Saving Integration

• Replaces multiple valves + pipe fittings

• Size reduction: DN50 3-way ball valves are 30-40% shorter than dual globe valve assemblies (per Industrial Valve Selection Handbook)

• Weight savings: Up to 25% vs equivalent gate valve setups

2. Performance Comparison: Critical Metrics

2.1 vs Gate Valves

| Parameter | 3-Way Ball Valve | Gate Valve |

|---|---|---|

| Sealing | Soft seals (PTFE): ≤0.01% leakage | Metal seals: ~0.1% leakage |

| (ISO 5208 Class VI) | (ISO 5208 Class IV) | |

| Operation Speed | 90° rotation (1-2 sec) | Multi-turn handwheel (10+ sec) |

| Maintenance | 100,000+ cycles (stem seal life) | Frequent gland packing repair |

2.2 vs Globe Valves

| Parameter | 3-Way Ball Valve | Globe Valve |

|---|---|---|

| Flow Resistance | Kv=0.05 (near-zero pressure drop) | Kv=5.0 (high turbulence) |

| Service Life | 10-year lifespan (no seat replacement) | Annual disc/seal replacement |

| Cost Efficiency | Lower TCO by 35% (reduced maintenance) | High spare part consumption |

Source: “Engineering Fluid Mechanics Applications” pressure loss data

2.3 vs Butterfly Valves

| Parameter | 3-Way Ball Valve | Butterfly Valve |

|---|---|---|

| Pressure Rating | PN64 (ASME Class 400) | Max PN16 (Class 150) |

| Bubble-Tight Seal | Achievable down to 0 bar | Limited at low pressure |

| Cost Advantage | Optimal for DN15-DN200 lines | Cheaper for DN300+ systems |

Key Selection Guidelines

✅ Choose 3-way ball valves when you need:

• Flow mixing/diversion in chemical dosing

• Zero-leakage sealing for hazardous media

• Space-constrained installations (e.g., skid-mounted systems)

⚠️ Consider alternatives for:

• Low-cost large-diameter water lines (use butterfly valves)

• High-precision throttling (globe valves preferred)

Key Applications and Working Conditions

3-way ball valves are used across industries due to their adaptability:

- Industrial: Control steam, gases, or corrosive fluids in chemical plants.

- HVAC: Manage heating/cooling water distribution.

- Water Treatment: Divert or mix fluids in filtration systems.

- Oil and Gas: Handle high-pressure pipelines.

Stainless steel 3-way ball valves excel in extreme conditions, including high temperatures, corrosive media, and high-pressure systems.

Advantages of 3-Way Ball Valves

- Multi-Functionality: Perform mixing, diverting, and shut-off tasks with a single valve.

- Compact Design: Save space compared to using multiple 2-way valves.

- Durability: Stainless steel variants resist rust, erosion, and chemical damage.

- Low Maintenance: Simple structure with fewer leakage points.

- Quick Operation: 90-degree rotation enables fast flow control.

Choosing the Right 3-Way Ball Valve

Selecting the correct type depends on your system’s needs:

- Use L-type for switching between two outlets.

- Opt for T-type to mix or split flows.

- Choose Y-type for low-resistance diversion.

- For corrosive environments, prioritize stainless steel 3-way ball valves.

Conclusion

3-way ball valves are essential for efficient flow control in complex piping systems. Understanding the differences between L type, T type, and Y type valves—along with material choices like stainless steel—ensures optimal performance. Whether in industrial plants, water treatment, or HVAC systems, these valves offer reliability, versatility, and longevity.

Post time: Mar-03-2025