Introduction

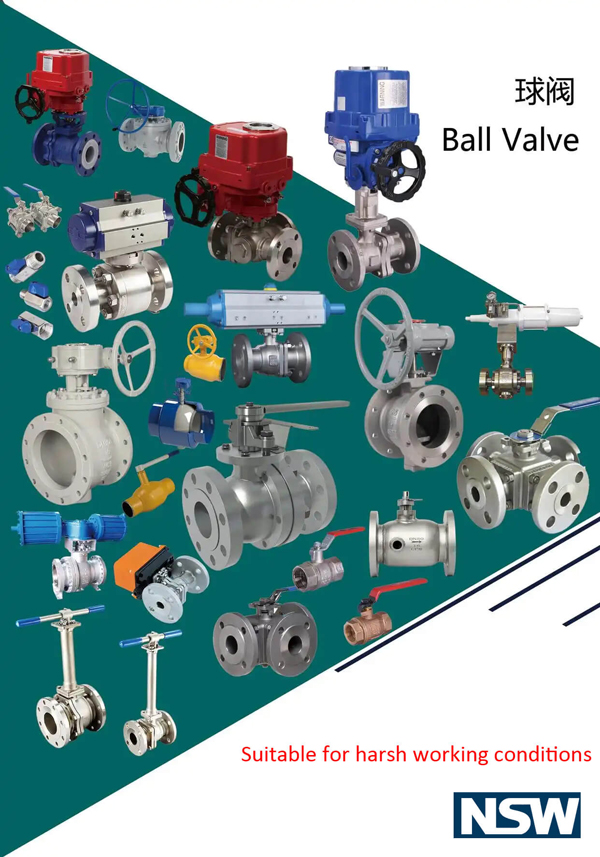

Ball Valves are widely used across industrial systems due to their reliability, fast operation, and tight shut-off performance. However, when installed in hazardous locations—such as oil & gas facilities, chemical plants, refineries, and mining operations—standard valve designs are often insufficient.

Hazardous environments introduce risks including flammable gases, combustible dust, extreme temperatures, corrosive media, and potential ignition sources. To operate safely and reliably under these conditions, Ball Valves must be specifically engineered, certified, and tested for hazardous location service.

This article explains how ball valves are adapted for hazardous locations, focusing on design modifications, material selection, certifications, and practical selection guidance for industrial users.

modifications, material selection, certifications, and practical selection guidance for industrial users.

What Is Considered a Hazardous Location?

A hazardous location is defined as an area where flammable gases, vapors, liquids, or combustible dusts may be present in quantities sufficient to create a risk of fire or explosion.

Common classification systems include:

-

IEC / ATEX Zones

-

Zone 0 / 20: Continuous presence of explosive atmosphere

-

Zone 1 / 21: Likely presence during normal operation

-

Zone 2 / 22: Unlikely, short-duration presence

-

-

NEC / CEC Classes and Divisions

-

Class I: Gases and vapors

-

Class II: Combustible dust

-

Class III: Fibers and flyings

-

Ball valves used in these environments must comply with the applicable classification and regulatory requirements.

Key Design Adaptations for Hazardous Location Ball Valves

1. Anti-Static (Electrostatic Discharge) Design

In hazardous atmospheres, static electricity can act as an ignition source. To mitigate this risk, hazardous-duty ball valves incorporate anti-static devices that ensure electrical continuity between:

-

Ball and stem

-

Stem and body

This prevents static charge accumulation during valve operation, especially in high-flow or dry gas applications.

2. Fire-Safe Construction

Fire-safe ball valves are designed to maintain sealing integrity even after exposure to fire.

Typical features include:

-

Metal-to-metal secondary sealing

-

Graphite or fire-resistant stem packing

-

Compliance with standards such as API 607, API 6FA, or ISO 10497

Fire-safe design is critical in oil & gas, petrochemical, and refinery applications.

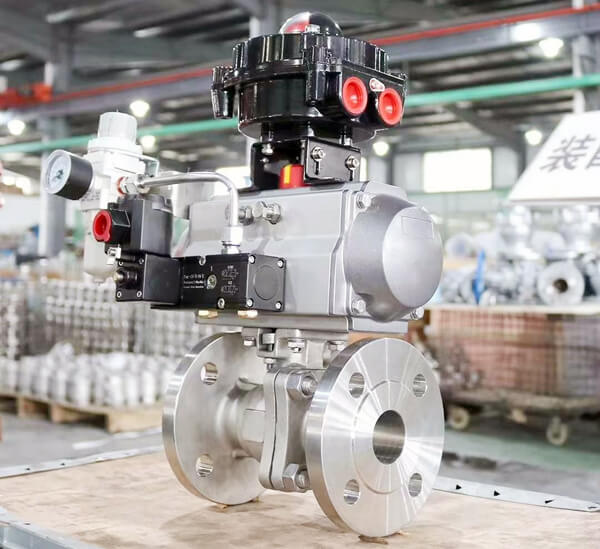

3. Explosion-Proof and Hazard-Rated Actuation

When ball valves are automated, the actuator becomes a critical safety component.

Hazardous location ball valves may be equipped with:

-

Explosion-proof electric actuators

-

Pneumatic actuators with certified solenoids

-

Enclosures rated to ATEX, IECEx, UL, or CSA

These actuators are designed to prevent internal ignition from propagating to the external environment.

4. Enhanced Sealing and Fugitive Emissions Control

Leakage of hazardous media poses safety and environmental risks. Adapted ball valves use:

-

Low-emission stem packing (graphite or PTFE-based systems)

-

Live-loaded packing arrangements

-

Compliance with ISO 15848 or API 622

This ensures long-term sealing performance under pressure, vibration, and temperature cycling.

5. Robust Materials for Harsh Conditions

Material selection is critical in hazardous environments.

Common adaptations include:

-

Stainless steel, duplex, or super duplex bodies

-

Corrosion-resistant alloys (Inconel, Monel, Hastelloy)

-

Anti-corrosion coatings for external protection

-

Extended temperature-rated seats and seals

These materials enhance durability in corrosive, high-pressure, or extreme-temperature service.

Typical Applications of Hazardous Location Ball Valves

Ball valves adapted for hazardous locations are widely used in:

-

Oil & gas upstream, midstream, and downstream systems

-

Chemical and petrochemical processing plants

-

LNG and LPG handling facilities

-

Offshore platforms

-

Mining and bulk material handling

-

Paint, solvent, and pharmaceutical production

In these applications, valve failure can result in serious safety incidents, making proper valve specification essential.

How to Select the Right Ball Valve for Hazardous Locations

When selecting a ball valve for hazardous service, consider the following factors:

Operating Conditions

-

Pressure and temperature range

-

Media type (gas, liquid, slurry)

-

Presence of corrosive or abrasive substances

Hazard Classification

-

Zone / Class / Division requirements

-

Required certifications (ATEX, IECEx, UL, etc.)

Valve Configuration

-

Floating or trunnion-mounted design

-

Fire-safe and anti-static requirements

-

Manual or automated operation

Compliance and Documentation

-

Test certificates

-

Material traceability

-

Quality and inspection records

Selecting a valve that meets both process requirements and regulatory standards is essential for long-term safety and compliance.

Relevant Standards and Certifications

Hazardous location ball valves commonly comply with:

-

ATEX Directive (2014/34/EU)

-

IECEx Certification Scheme

-

API 607 / API 6FA (Fire testing)

-

ISO 15848 (Fugitive emissions)

-

NACE MR0175 / ISO 15156 (Sour service)

Always verify certification scope and suitability for the specific application.

Frequently Asked Questions (FAQ)

Are standard ball valves suitable for hazardous locations?

No. Standard ball valves typically lack anti-static design, fire-safe construction, and certified actuation required for hazardous environments.

Do all hazardous location ball valves need explosion-proof actuators?

Only automated valves require explosion-proof or hazard-rated actuators. Manual valves still require anti-static and fire-safe features.

What is the difference between ATEX and IECEx certification?

ATEX is a European directive, while IECEx is an international certification scheme. Both address equipment safety in explosive atmospheres, but acceptance depends on regional regulations.

How often should hazardous location valves be inspected?

Inspection frequency depends on service severity, but regular inspection and maintenance are strongly recommended to ensure ongoing compliance and safety.

Conclusion

Ball valves used in hazardous locations require specialized design, certified components, and strict compliance with international standards. By incorporating anti-static features, fire-safe construction, explosion-proof actuation, and robust materials, these valves can operate safely in some of the most demanding industrial environments.

For engineers, EPC contractors, and procurement professionals, understanding how ball valves are adapted for hazardous locations is essential to making informed, compliant, and cost-effective valve selections.

Post time: Mar-14-2025