Introduction to Gas Ball Valves

In the world of fluid and gas control, selecting the right valve is paramount for ensuring safety, efficiency, and reliability in both industrial and residential systems. Among the various options, the Gas Ball Valve distinguishes itself through its robust performance, durability, and straightforward operation. This comprehensive guide delves into the specifics of gas ball valves, explores their advantages over alternatives like gate and globe valves, and underscores the significant role of Gas Ball Valve Manufacturers in the global supply of high-quality valve solutions.

What is a Gas Ball Valve?

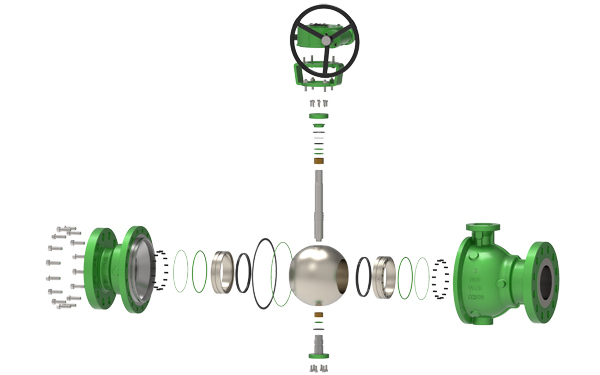

A Gas Ball Valve is a type of quarter-turn valve that utilizes a hollow, perforated ball to control the flow of gases or fluids. Rotating the valve handle 90 degrees shifts the ball to either permit or block flow. Specifically engineered to manage combustible gases safely, these valves provide excellent sealing capabilities and leak-proof performance. Their quick operation and minimal maintenance make them a preferred choice as Gas Shut Off Valves in pipelines, HVAC systems, and various types of industrial equipment.

These valves are characterized by their simple, compact design, low weight, and ease of maintenance. They offer quick open/close operation (as fast as 0.05 seconds per actuation in some pneumatic models), low fluid resistance, and bidirectional flow capability. They are designed to meet stringent international standards for fire safety (e.g., API 6FA) and can be equipped with features like anti-static devices and extended valve necks for specific applications.

Are Ball Valves Suitable for Gas Applications?

Yes, ball valves are highly suitable for gas applications, provided they are constructed from appropriate materials and hold necessary certifications. Unlike Gate Valves (best for simple on/off control in liquid systems) or Globe Valves (ideal for flow regulation), Gas Ball Valves excel in environments that demand rapid shut-off and reliable performance under high pressure.

Key features that ensure their safety and efficacy for gas include:

• Robust Construction: Materials like stainless steel, brass, and carbon steel prevent corrosion and enhance longevity.

• Advanced Sealing: Seals made from PTFE (Polytetrafluoroethylene) or similar materials ensure zero leakage, even under extreme temperature fluctuations.

• Safety-Certified Designs: Reputable manufacturers design valves to meet international standards such as ISO, API (American Petroleum Institute), and ASME, often including fire-safe designs.

How Gas Ball Valves Work

Gas Ball Valves function as essential equipment for initiating and halting the flow of media within pipelines and systems. They are primarily used to control the flow of natural gas, liquefied petroleum gas (LPG), and other combustible gases.

These valves typically cover a nominal diameter (DN) range from DN15 to DN200 and nominal pressures (PN) from PN1.6 to PN4.0 MPa. They can operate in a wide temperature range, from cryogenic conditions as low as -196°C to elevated temperatures up to +80°C or higher, with valve bodies commonly crafted from stainless steel for durability and resistance.

The core operation involves rotating a ball with a circular passage. This allows for swift opening and closing, easy operation, and minimal fluid resistance. Their simple, compact design makes them lightweight and easy to maintain. Specialized designs may include:

• Long Neck Valves: To prevent cold energy loss in cryogenic applications.

• Anti-Static Devices: Such as spring-loaded mechanisms to ensure electrical continuity and prevent static buildup.

• Fire-Safe Structures: Complying with standards like API 6FA to maintain integrity in fire events.

• Non-Metal Components: Valves with materials like PA12 can be certified (e.g., to ISO16486-4) for specific medium-pressure and trenchless installation scenarios, operating with low noise and vibration.

Installation requires ensuring adequate space for the handle to rotate and, for actuators, typically a vertical mounting orientation.

Types of Gas Ball Valves

Gas Ball Valves can be categorized based on their structure, operation method, and connection type, each suited to different pressures, temperatures, and control needs.

By Valve Structure

• Floating Ball Valve: The ball is free to rotate slightly within the valve body, suitable for higher pressure applications.

• Fixed Ball Valve: The ball is fixed in place within the valve, offering stable sealing performance and is often used for larger diameters and higher pressures.

• Flexible Ball Valve: Incorporates an elastic sealing structure, ideal for low-temperature and low-pressure scenarios.

By Number of Ports and Flow Paths

• Two-Way (Straight-Through) Valve: Standard design where fluid passes straight through.

• Three-Way (T-Port or L-Port) Valve: Used for diverting, mixing, or shutting off flow between multiple pipelines.

By Actuation Method

• Manual Ball Valve: Operated by a handle or gear mechanism.

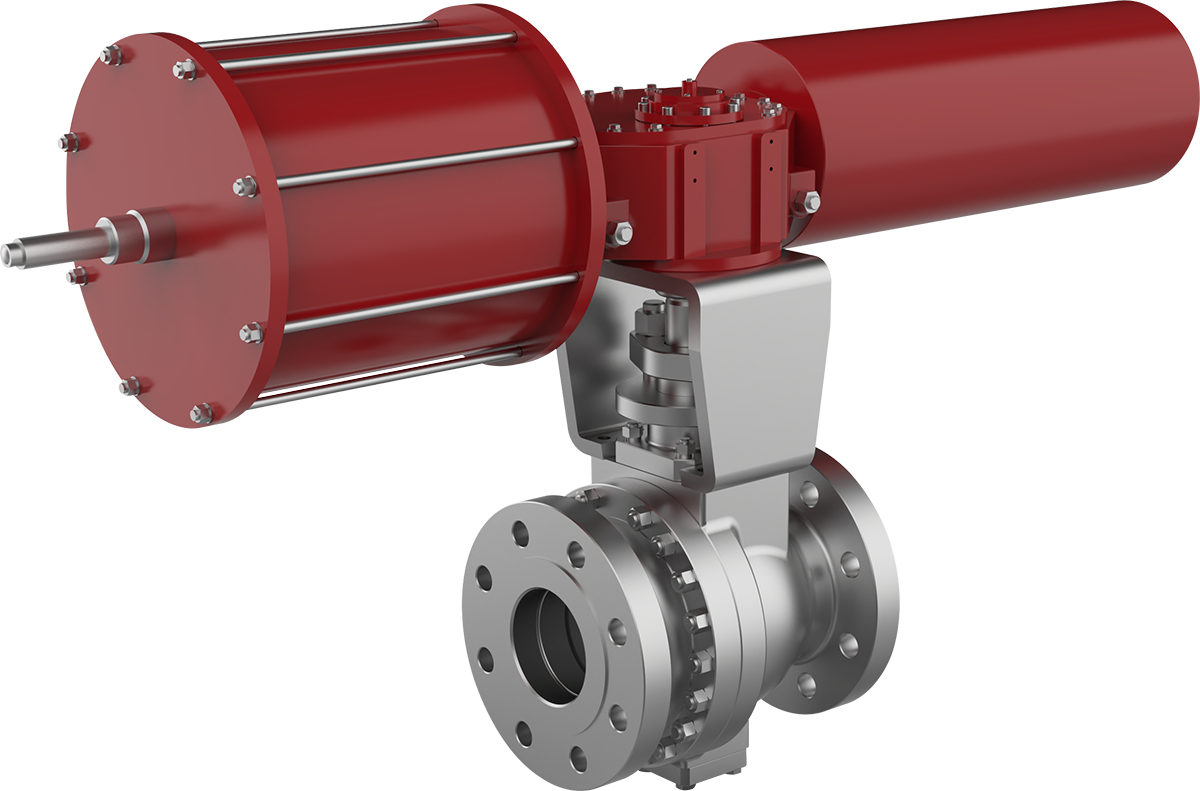

• Pneumatic Ball Valve: Equipped with a pneumatic actuator for very fast switching speeds (e.g., 0.05 seconds/cycle) and are ideal for remote or automated industrial control systems.

• Electric Ball Valve: Driven by an electric motor for automated on/off or modulating control.

• Worm Gear Ball Valve: Uses a worm gear reduction mechanism for easier operation of larger valves and remote control.

By Connection Type

• Threaded Connection: Common for small-bore piping.

• Flanged Connection: Utilizes flanges for bolting to the pipeline, standard for large-bore piping and high-pressure systems.

• Welded Connection: Directly welded to the pipeline, offering the best seal for critical applications.

Specialized Types

• Natural Gas Specialty Ball Valves: Specific designs like the Q41F type for liquefied natural gas (LNG), often featuring a fixed structure and materials suited for cryogenic service.

Gas Ball Valve Applications

Residential Applications

In homes, Gas Ball Valves are primarily installed as master shut-off controls on gas supply lines, often located at the building’s base or on specific floors to manage the gas supply for an entire unit. Regulations typically prohibit residents from operating these valves themselves except in emergencies.

Residential gas valves include:

• Public Gas Main Valve: Managed by the gas utility or property management for system-wide maintenance.

• Meter Valve (Valve before the gas meter): Isolates the meter for servicing; operated by professionals.

• Appliance Valve (Valve before the cooker): Located near the gas appliance; recommended to be closed after each use for safety.

Modern regulations, like China’s 2022 “Gas Engineering Code,” may require installing automatic shut-off valves that function differently from ball valves, cutting flow during pressure or flow anomalies.

Industrial Applications

In industrial settings, Gas Ball Valves are critical for transmission, safety control, and process regulation.

• Gas Transmission Pipelines: Used in natural gas transmission and LPG storage/evaporation processes. Pneumatic actuation enables rapid shut-off (0.05 sec/cycle) and integration with solenoids and positioners for remote control.

• Emergency Shutdown Valve (ESDV): In stations like CNG refueling or separation plants, valves feature explosion-proof designs (per API 6A) for remote emergency shut-down, ensuring safety.

• Cryogenic Applications: At LNG terminals, valves require low-temperature seals (per ASME B16.34) to perform at temperatures as low as -162°C, preventing leaks and frost formation.

• Flow Regulation: In chemical plants and refineries, specially designed ball valves control feedstock flow, needing to withstand high temperatures (400°C+) and corrosive media.

• Maintenance & Safety: Top-entry design allows for in-line maintenance without removing the valve from the pipeline. Actuators often require explosion-proof certifications (ATEX/IECEx) for safe operation in hazardous areas.

Advantages of Using Gas Ball Valves

The widespread use of Gas Ball Valves is driven by several key benefits:

• Compact and Lightweight Design: Their simple structure makes them smaller and lighter than many alternative valves, simplifying installation and saving space.

• Excellent Sealing Performance: The surface contact sealing design maintains an effective seal even under high pressure and is bidirectional.

• Quick Operation and Fast Response: The 90-degree operation allows for extremely fast opening and closing, especially with pneumatic actuators (0.05-0.1 seconds).

• Low Flow Resistance and Corrosion Resistance: The full-bore design offers minimal flow restriction, reducing energy loss. They are suitable for various corrosive media like gas and steam.

• Low Maintenance Costs: Simple construction leads to easy maintenance, low failure rates, and reduced long-term operating expenses.

Installation and Maintenance Tips

Proper installation and upkeep are crucial for optimal performance and safety.

Installation Steps

1. Preparation: Ensure the pipeline and valve are coaxially aligned. Flange sealing surfaces must be parallel, clean, and free of debris. Visually inspect the valve and perform a full open/close test.

2. Connection and Securing: Install seal gaskets, uniformly applying a suitable sealant (e.g., PTFE). Tighten bolts symmetrically and gradually to avoid flange distortion and potential leaks.

3. Actuator Installation: Valves with actuators (pneumatic or electric) must typically be installed vertically. Ensure the operating handle has a clear path for rotation. After installation, check for smooth operation and conduct a pressure test to verify sealing.

Maintenance Tips

• Routine Inspection: Regularly clean the valve interior and sealing surfaces to prevent damage from debris. Check for loose bolts and leaks at connection points.

• Disassembly and Cleaning: Always depressurize the pipeline before disassembly. Clean non-metallic parts (like O-rings) promptly and avoid prolonged immersion.

• Lubrication and Care: Use a lubricant compatible with the gas media (e.g., special grease 221 for gas). Apply a thin layer on seal surfaces during assembly to reduce friction.

Important Notes

• Do NOT use a ball valve for throttling; this can cause seat erosion and seal failure due to pressure instability.

• Install away from high-stress areas on the pipeline to ensure long-term stable operation.

Troubleshooting Common Issues

Even reliable valves can experience problems. Here’s a quick guide:

| Problem | Potential Causes | Solutions |

|---|---|---|

| Valve Sticking/Cranking | Foreign material/debris, stem misalignment, seal wear. | Clear debris, inspect and realign stem, replace damaged seals, lubricate ball and seats regularly. |

| Leakage | Damaged seal faces, aged gaskets/O-rings, loose fasteners, improper installation. | Replace seals/gaskets, tighten fasteners, ensure proper installation. |

| Difficult Operation | Low air supply (pneumatic), faulty wiring/contacts (electric), clogged/damaged solenoid valve. | Check air pressure, inspect electrical connections, clean or replace solenoid valve. |

General Maintenance Advice:

• Cycle the valve at least annually, lubricate as needed.

• Regularly remove external rust and contaminants.

• Drain water from the valve cavity before winter to prevent freezing damage.

Critical Safety Notes

As crucial safety components, heed these precautions:

• Installation & Maintenance: Install with adequate clearance for handle operation. Upright installation is mandatory for valves with actuators. Regularly verify the valve’s open/closed status.

• Operational Rules: Public and meter valves are typically off-limits to unauthorized personnel per gas management regulations. In a leak emergency, shut off the meter valve, ventilate the area, and call professionals immediately.

• Key Reminders: The valve handle parallel to the pipe means OPEN; perpendicular means CLOSED. Never use a ball valve to regulate flow.

The Future and Trends of Gas Ball Valve Technology

Gas ball valve technology continues to evolve, focusing on enhanced reliability, intelligence, and adaptability.

Current technology highlights include reliable soft and metal-sealed designs for high-pressure gas, construction from corrosion-resistant materials like stainless steel, and support for various actuation methods for automation.

Future trends point towards:

• Smart Integration: Incorporating sensors and IoT capabilities for real-time monitoring of valve position, pressure, temperature, and leakage, enabling predictive maintenance and early fault warnings.

• Modular Design: Designs that facilitate easier maintenance, part replacement, and system upgrades, reducing downtime and lifecycle costs.

• Enhanced Performance: Continuous improvement in materials and design to handle challenging conditions, such as resisting corrosion from gas impurities and enhancing overall durability. The market, especially for automated valves like pneumatic ball valves, is expected to see significant growth, driven by industries like oil & gas, water treatment, and new energy, with the Asia-Pacific region, led by China, being a major demand driver.

Ball Valves vs. Gate Valves and Globe Valves

While gate and globe valves have their places, they are generally less efficient for dedicated gas on/off service compared to ball valves.

• Gate Valves: Operate slowly via a multi-turn handwheel, are more prone to wear and leakage over time, and are not designed for rapid shutdown.

• Globe Valves: Cause significant pressure drops due to their flow path and are also slower to operate; best used for flow throttling, not simple isolation.

• Gas Ball Valves: Provide faster shut-off (quarter-turn operation), require lower maintenance (fewer moving parts), and allow for bidirectional flow without issues.

Selecting a Trusted Gas Ball Valve Manufacturer

China has become a global powerhouse for valve manufacturing, hosting numerous producers and suppliers that deliver cost-effective, high-performance solutions.

When choosing a Gas Ball Valve manufacturer or supplier, consider:

1. Certifications & Standards: Verify compliance with relevant international standards (ANSI, CE, UL, API, ISO) and industry-specific certifications.

2. Customization Capability: Look for providers offering bespoke designs, materials, and actuation options for unique application requirements.

3. Quality Assurance: Reputable Chinese manufacturers employ rigorous quality control protocols, material testing, and factory audits to ensure product reliability.

The Advantage of Sourcing from Chinese Valve Suppliers

Partnering with established Gas Valve manufacturers in China offers distinct benefits:

• Cost-Effectiveness: Economies of scale and manufacturing expertise often result in highly competitive pricing without sacrificing quality.

• Rapid Delivery: Strong, well-established global logistics networks enable timely shipping to international markets.

• Technical Expertise: Many leading Chinese manufacturers possess deep engineering knowledge and offer robust technical support and after-sales service.

Conclusion

For controlling gas flow safely and efficiently, Gas Ball Valves are the superior choice, outperforming alternatives like gate and globe valves in speed, sealing reliability, and longevity. Their versatility makes them essential across residential, commercial, and industrial settings.

When sourcing these critical components, partnering with a certified and reputable China-based manufacturer or supplier provides access to durable, compliant, and affordable solutions. Whether you’re maintaining existing infrastructure or designing a new system, investing in a high-quality Gas Ball Valve is an investment in safety, performance, and operational efficiency. The future of gas ball valves is smart, efficient, and driven by innovation from global leaders, including those in China.

Post time: Feb-22-2025