Full Port vs Reduced Port Ball Valves: Key Differences and Selection Guide

Ball valves are critical components in fluid control systems, classified into two main types: full port (full bore) and reduced port (reduced bore). Understanding their differences ensures optimal performance and cost efficiency in industrial applications.

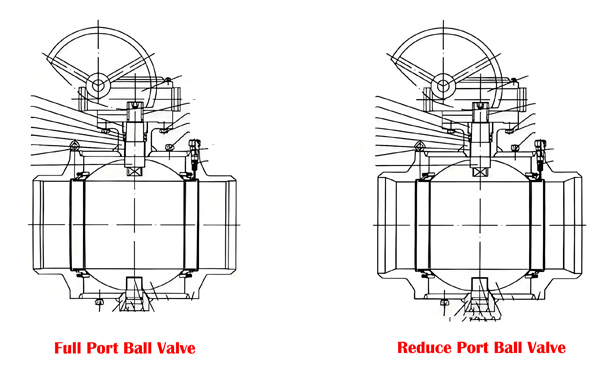

Defining Full Port vs Reduced Port Ball Valves

- Full Port Ball Valve: The valve’s inner diameter matches ≥95% of the pipeline’s nominal diameter (e.g., a 2-inch valve has a 50mm flow path).

Tips: When selecting a ball valve, the full-bore 2 Inch ball valve has the valve size written as NPS 2.

- Reduced Port Ball Valve: The inner diameter is ≤85% of the pipeline’s nominal diameter (e.g., a 2-inch valve has a ~38mm flow path).

Tip: When selecting a ball valve, the reduced-bore 2 Inch ball valve has the valve size written as NPS 2 x 1-1/2

Key Structural Differences

| Feature | Full Bore Ball Valve | Reduced Bore Ball Valve |

|---|---|---|

| Flow Path Design | Equal to pipeline diameter; no narrowing | 1-2 sizes smaller than pipeline |

| Flow Efficiency | Zero flow restriction; minimal pressure drop | Higher resistance than full bore |

| Valve Sizing (NPS) | Matches pipeline (e.g., NPS 2) | Denotes reduction (e.g., NPS 2 × 1½) |

| Weight & Compactness | Heavier; robust construction | 30% lighter; space-saving design |

Performance and Application Comparison

| Factor | Full Bore Ball Valve | Reduced Bore Ball Valve |

|---|---|---|

| Ideal Media | Viscous fluids (crude oil, slurry), pigging systems | Gases, water, low-viscosity fluids |

| Flow Requirements | Maximum flow with minimal resistance | Controlled flow; adjustable capacity |

| Typical Use Cases | Main pipelines (oil/gas), cleaning systems | Branch lines, budget-sensitive projects |

| Pressure Drop | Near-zero resistance; ideal for long pipes | Higher local pressure drop |

| Cost Efficiency | Higher upfront cost | 30% lower cost; reduced pipe load |

How to Choose the Right Ball Valve

Prioritize Full Bore If:

1. Handling viscous/slurry media or requiring pigging.

2. System demands maximum flow with minimal pressure loss.

3. Pipeline cleaning/maintenance is routine.

Choose Reduced Bore When:

1. Working with gases or low-viscosity liquids.

2. Budget constraints exist; lightweight valves are preferred.

3. Flow control and space optimization are critical.

Why It Matters

1. Full Bore Valves eliminate flow restrictions, reducing energy costs in long-distance transport.

2. Reduced Bore Valves offer cost savings (up to 1/3 cheaper) and efficient flow control for compact systems, while reducing structural load on pipelines.

Post time: Jun-25-2025