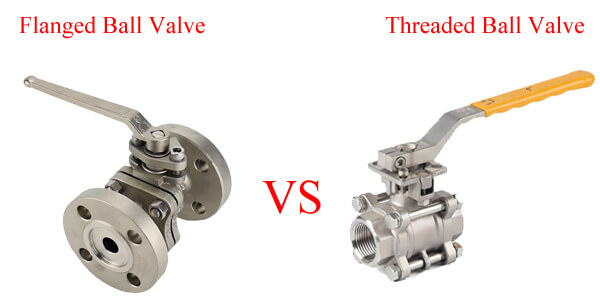

The choice between a flanged ball valve and a threaded ball valve is a fundamental engineering decision that extends far beyond mere connection type. It directly impacts the integrity, safety, maintenance lifecycle, and total cost of your piping system. While cost and simplicity are often initial drivers, a deep understanding of performance characteristics is crucial for optimal selection.

This guide moves beyond a basic comparison to provide a detailed analytical framework, helping you specify the right valve connection for your specific pressure, maintenance, and operational requirements.

Core Design Philosophy: Permanent vs. Serviceable

The distinction is rooted in the intended lifecycle and serviceability of the system.

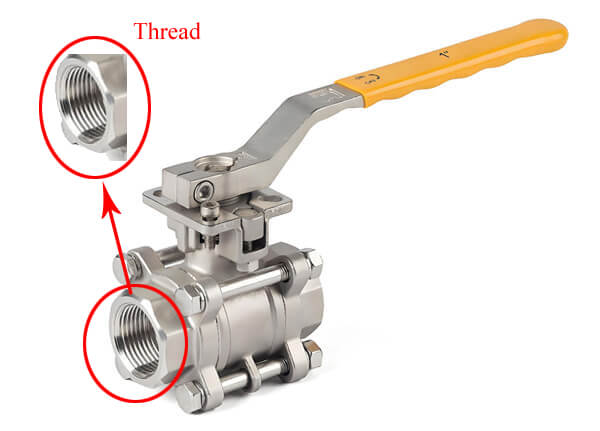

Threaded Ball Valves: The Compact, Permanent Solution

A threaded ball valve utilizes National Pipe Taper (NPT) threads to screw directly onto the piping. The tapered thread design creates a metal-to-metal wedge that, with the aid of a sealant, prevents leaks. This design philosophy favors compact, low-cost, and largely permanent installations where disassembly is not anticipated.

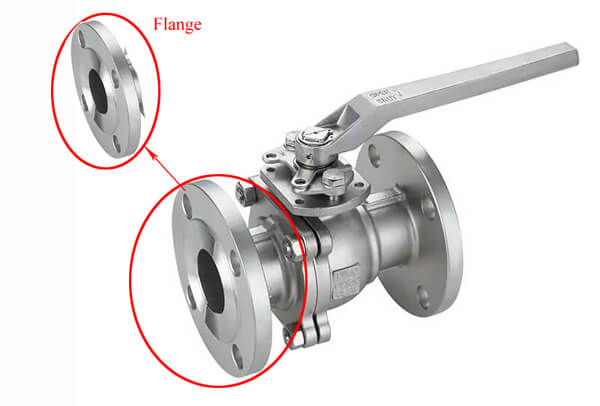

Flanged Ball Valves: The High-Performance, Serviceable Solution

A flanged ball valve features machined flanges that are bolted to matching pipe flanges, with a gasket compressed between them to create a seal. This design is built for high-integrity, serviceable, and modular systems. It allows for easy installation, removal, and inspection without system alteration, making it the standard for critical applications.

Analytical Comparison: Performance Under Pressure

A simple list of pros and cons is not enough. Here’s a data-driven breakdown of key performance factors.

1. Pressure and Temperature Capability

- Threaded Connection: The threads themselves are a potential failure point under stress. They are susceptible to stress corrosion cracking and can leak under significant thermal cycling. Best suited for Class 800 ratings and below, typically in applications under 200-300 PSI.

- Flanged Connection: The bolted connection distributes load evenly, and the face-to-face gasket seal is exceptionally robust. Designed to standardized pressure classes (ANSI Class 150, 300, 600, 900, 1500, 2500), flanged valves reliably handle pressures exceeding 1000 PSI and high-temperature fluids.

2. Installation, Maintenance, and Total Cost of Ownership (TCO)

Threaded Valve TCO:

- Installation: Faster initial install; requires sealant and proper threading technique.

- Maintenance: The primary disadvantage. Disassembly often requires backing the valve off the pipe, which can be impossible due to corrosion or system alignment, forcing costly pipe cutting.

- TCO: Lower initial cost, but potential for higher long-term maintenance expenses.

Flanged Valve TCO:

- Installation: More complex; requires correct gasket selection, bolt tightening sequence, and torque values.

- Maintenance: Unmatched. The valve can be unbolted and lifted straight out for service, replacement, or inspection, minimizing system downtime.

- TCO: Higher initial investment (valve, gaskets, bolts), but significantly lower lifetime maintenance costs and downtime in critical systems.

3. System Integrity and Application Suitability

Threaded Valves Excel In:

- Size: Small bore piping (**

Threaded Valves Excel In:

- Size: Small bore piping (2 inches and below).

- Applications: Residential plumbing, HVAC, low-pressure water/air lines, OEM equipment, and chemical injection systems where space is constrained.

- Environment: Stable systems with minimal vibration and thermal cycling.

Flanged Valves Are Essential For:

- Size: 2 inches and above (standard), though commonly used down to 1/2″ for critical service.

- Applications: Oil & gas production, chemical processing, power generation, fire protection mains, steam systems, and any process with hazardous media.

- Environment: Systems with high vibration, pressure surges, thermal expansion, or requiring regular isolation.

Decision Matrix: Selecting the Right Connection

| Design Factor | Threaded Ball Valve | Flanged Ball Valve |

|---|---|---|

| Max Operating Pressure | Low to Medium | Very High |

| Pipe Size Range | ½” – 2″ | 2″ and larger (Standard) |

| Initial Cost | Lower | Higher |

| Maintenance & Repair | Difficult, Often Destructive | Easy, Bolted Disassembly |

| System Vibration | Poor Performance | Excellent Resistance |

| Space Requirements | Compact | Requires More Space |

| Best For | Permanent, Low-Cost Systems | Serviceable, Critical Systems |

Beyond the Basics: Critical Selection Considerations

- Gasket Selection: For flanged valves, the gasket is a critical consumable. Material (e.g., EPDM, PTFE, Graphite) must be compatible with the fluid, temperature, and pressure.

- Proper Installation: NPT threads must be properly sealed with a thread compound or tape. Flanged joints must be bolted using a cross-pattern torque sequence to ensure even gasket compression and prevent leaks.

- Material Compatibility: Ensure the valve body material (WCB, CF8M, etc.) and trim are compatible with your process fluid to avoid galvanic corrosion or chemical degradation.

Conclusion: A Question of System Philosophy

The flanged vs. threaded debate is not about which is better, but which is appropriate for your system’s philosophy.

- Choose a threaded ball valve for cost-effective, compact, and likely permanent solutions in low-to-medium pressure services.

- Choose a flanged ball valve for high-pressure, critical, or maintenance-intensive applications where system integrity, safety, and operational flexibility are paramount.

At NSW Valve, we provide more than just valves; we provide expertise. Our engineering team can help you navigate these considerations to specify the perfect valve solution, ensuring reliability and efficiency from design to operation.

Ready to specify with confidence? [Explore our technical specifications for flanged and threaded ball valves] or [Contact our engineering support team] for a personalized consultation.

Post time: Sep-05-2025