What is an Emergency Shutdown Valve (ESDV)

In the high-stakes world of industrial process plants, particularly oil and gas refineries, chemical plants, and power generation facilities, safety isn’t just a priority – it’s an absolute imperative. At the heart of safeguarding personnel, protecting the environment, and preventing catastrophic asset damage lies a critical piece of equipment: the Emergency Shutdown Valve (ESDV), also frequently referred to simply as a Shutdown Valve (SDV) within Safety Instrumented Systems (SIS).

An ESDV is a specialized, automatically actuated valve designed for one paramount purpose: to rapidly and reliably isolate sections of a process flow (liquids, gases, or multiphase fluids) in the event of a predefined emergency condition. Unlike control valves that modulate flow for process regulation, ESDVs are binary operators – they are either fully open (allowing flow during normal operation) or fully closed (blocking flow during an emergency). Their core function is to act as the primary physical barrier stopping the uncontrolled release of hazardous materials when critical safety limits are exceeded.

Why ESDVs are Non-Negotiable for Safety

The consequences of failing to isolate process flow during emergencies like fires, leaks, overpressure, equipment failure, or loss of containment can be devastating. ESDVs are integral components of Safety Instrumented Functions (SIFs) within a broader Safety Instrumented System (SIS). These systems are designed according to rigorous international standards (IEC 61511 / ISA 84) and assigned Safety Integrity Levels (SIL) based on the risk reduction they must achieve.

Key Characteristics Defining an ESDV:

1. Fail-Safe Design: This is the cornerstone principle. ESDVs are designed to move *automatically* to their safe state (almost always fully closed, but sometimes *open* in specific scenarios like cooling water supply during fire) upon loss of the actuating power source (electricity, air pressure, hydraulic pressure) or upon receiving a specific trip signal from the SIS. This ensures safety even if the plant loses power or control.

2. High Reliability & Availability: ESDVs undergo stringent design, manufacturing, testing, and certification processes. They must function on demand, every time. Redundancy in critical components (like solenoids) is common.

3. Fast Closing Time: Speed is critical in emergencies. ESDVs are specified to close within very short timeframes, typically 1 to 5 seconds, depending on the valve size, type, and the specific safety requirement (SIL level).

4. Positive Sealing: When closed, ESDVs must provide a bubble-tight seal to prevent any leakage of the hazardous process fluid.

5. Rugged Construction: Built to withstand harsh process conditions (high pressure, temperature, corrosive fluids) and potential fire exposure (fire-safe design per API 607/6FA, ISO 10497 is often mandatory).

6. Independent Control: ESDVs receive their trip signal directly from the dedicated Safety Instrumented System (SIS), not the regular process control system (BPCS). This separation is crucial for reliability.

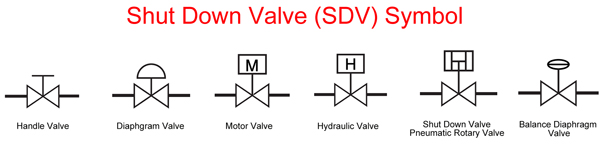

Seeing Safety: Emergency Shutdown Valve P&ID Representation

Piping and Instrumentation Diagrams (P&ID) are the universal language for process engineers. ESDVs have distinct symbols to differentiate them from other valve types and clearly indicate their critical safety role.

* Standard Valve Symbol: The basic symbol depends on the valve type:

* Ball Valve: Two triangles pointing towards a circle (representing the ball).

* Gate Valve: A sliding rectangle between two vertical lines (representing the gate and body).

* Butterfly Valve: A straight line bisecting a circle (representing the disc and body).

* Actuator Symbol: The key identifier for an ESDV/SDV is its actuator symbol attached to the valve body:

* A square surrounding the valve symbol typically represents an actuator.

* For an ESDV, this square is usually filled in solid black or hatched.

* The letters “ESD”, “SD”, or “XV” (where X denotes a specific identifier, often ‘S’ for shutdown) are prominently displayed next to or within the actuator symbol.

* Fail Action: The fail-safe action is indicated by symbols near the actuator:

* FC (Fail Close): An arrow pointing towards the valve body or the letters “FC”. Most common for ESDVs.

* FO (Fail Open): An arrow pointing away from the valve body or the letters “FO”. Used in specific scenarios.

* Instrument Bubble & Tag Number: The ESDV is always linked to the SIS. Its function is shown by an instrument bubble (typically a hexagon or circle) connected to the valve actuator symbol by a dashed line. The tag number within the bubble follows plant standards but clearly identifies it as part of the SIS (e.g., ZV-1001, where ‘Z’ often denotes SIS/ESD, ‘V’ for valve).

Core Principle: How Does an Emergency Shutdown Valve Work

The working principle hinges on the fail-safe design and the actuator’s response to a signal or energy loss. Here’s a breakdown:

1. Normal Operation: The ESDV is held in the OPEN position. This requires energy:

* Spring-Return Actuators: The actuator (pneumatic/hydraulic) uses supplied pressure to *compress* a powerful spring, holding the valve open against the spring force.

* Motor Operators (Less Common for ESD): A motor holds the valve open (or closed) against a mechanical brake or spring. Loss of power triggers the fail-safe action.

2. Emergency Condition Detected: Sensors (pressure transmitters, temperature sensors, flame detectors, gas detectors, etc.) send a signal to the SIS logic solver indicating a critical hazard.

3. SIS Trip Signal: The SIS logic solver, based on its programmed safety logic, determines a trip is required. It sends an electrical signal to the ESDV’s solenoid valve(s).

4. Actuator Energy Dump (Key Step):

* Spring-Return: The solenoid valve(s) instantly *de-energize*, rapidly venting the air/hydraulic pressure *from* the actuator. The stored energy in the powerful compressed spring is released.

* Energy-to-Close: The spring force (or sometimes stored hydraulic pressure) overpowers any opposing forces and drives the actuator stem to rotate (ball/butterfly) or lift/lower (gate) the valve closure member.

5. Valve Closure: The closure member (ball, gate, disc) moves rapidly to the fully CLOSED position, physically blocking the process flow path.

6. Isolation Achieved: The hazardous process fluid is contained within the isolated section upstream of the ESDV, preventing escalation of the incident.

The Muscle Behind the Action: Emergency Shutdown Valve Actuators

The actuator is the powerhouse that converts the control signal (or loss of energy) into the mechanical force needed to move the valve quickly and reliably. Choosing the right actuator is critical for ESDV performance.

Common ESDV Actuator Types:

1. Pneumatic Spring-Return Diaphragm Actuators:

* Principle: Compressed air pressure acts on a large diaphragm to compress a spring, holding the valve open. Air dump (via solenoid valve) releases the spring, closing the valve.

* Pros: Simple, reliable, fast acting, intrinsically safe (no sparks), readily available air supply.

* Cons: Limited force for very large valves or high differential pressures, requires clean/dry air supply, potential for slower action in very cold environments.

* Common Use: Smaller to medium-sized ball valves and butterfly valves.

2. Hydraulic Spring-Return Piston Actuators:

* Principle: Hydraulic fluid pressure acts on a piston to compress a powerful spring, holding the valve open. Solenoid valve dumps hydraulic pressure, spring closes valve.

* Pros: Very high force output suitable for large valves, gate valves, and high differential pressure applications. Generally faster than large pneumatic actuators. Robust.

* Cons: Requires hydraulic power unit (HPU), more complex installation, potential for fluid leaks, higher maintenance.

* Common Use: Large ball valves, gate valves, high-pressure applications (especially oil & gas wellheads, pipelines).

3. Pneumatic/Hydraulic Scotch-Yoke or Rack & Pinion Actuators (Spring-Return):

* Principle: Convert linear piston/diaphragm motion into rotary motion via scotch-yoke or rack and pinion mechanisms. Spring-return provides fail-safe action.

* Pros: Excellent torque output throughout the stroke, compact design (rack & pinion), suitable for quarter-turn valves (ball, butterfly, plug). Combines force/speed advantages.

* Cons: Can be more complex than basic diaphragm actuators.

* Common Use: Wide range of ball and butterfly valve sizes.

4. Electric Motor Actuators (with Battery Backup/Fail-Safe Spring):

* Principle: An electric motor drives the valve open or closed. For ESDV use, they *must* incorporate a mechanical fail-safe mechanism, usually a spring, that engages upon loss of power to drive the valve to its safe state. Battery backup may power the motor for one last trip if power fails *after* a signal is received but before closure.

* Pros: No need for air/hydraulic systems, precise positioning (though not needed for ESD), high torque.

* Cons: Slower closing times compared to fluid power/spring, higher cost, complexity of spring mechanism, potential spark hazard (requires certification for hazardous areas).

* Common Use: Locations where air/hydraulic supply is impractical, or for smaller valves where speed is less critical. Less common for critical high-speed ESDV applications than fluid-powered spring-return.

Every Second Counts: Emergency Shutdown Valve Closing Time

Closing time is arguably one of the most critical performance specifications for an ESDV. It directly impacts the Safety Integrity Level (SIL) verification calculations for the Safety Instrumented Function (SIF).

* Why Speed Matters: In an emergency like a major leak or fire, the volume of hazardous material released before isolation is proportional to the flow rate and the time the valve takes to close. Faster closure minimizes release, reducing the severity of the incident (fire size, toxic cloud dispersion, environmental spill).

* Typical Requirements: ESDV closing times are typically specified in the range of 1 to 5 seconds from the initiation of the trip signal to achieving full closure and seal. Smaller valves (e.g., 2-6 inch) often achieve 1-2 seconds. Larger valves (e.g., 24 inch+) or gate valves might require up to 5 seconds or slightly more, though faster is always desirable.

* Factors Influencing Closing Time:

* Valve Size and Type: Larger valves have more mass to move. Gate valves require longer linear stroke than quarter-turn ball/butterfly valves.

* Actuator Type and Size: Hydraulic actuators generally close large valves faster than pneumatic. Actuator sizing (sufficient spring force/piston area) is crucial.

* Process Conditions: High differential pressure across the valve creates force opposing closure, requiring a more powerful actuator.

* Stiction and Friction: Valve stem packing friction and internal component friction must be minimized.

* Solenoid Valve Speed: The solenoid valve must vent actuator pressure extremely rapidly.

* Control System Delay: The time for the SIS logic solver to process the signal and energize/de-energize the solenoid adds to the overall time (though usually milliseconds).

* Testing:Partial Stroke Testing (PST) monitors valve movement without a full trip, but Full Stroke Testing (FST) during scheduled shutdowns is essential to verify the actual closing time meets specifications. High-performance ESDVs often have local mechanical indicators showing closure status.

Anatomy of Safety: Key Shutdown Valve Parts

Understanding the main components of an ESDV assembly is essential:

1. Valve Body: The primary pressure-containing component, housing the internal parts. Constructed from robust materials (carbon steel, stainless steel, alloys) suitable for pressure, temperature, and fluid corrosiveness. Includes flanged, welded, or threaded ends for piping connection. Fire-safe design per API 607/6FA, ISO 10497 is critical.

2. Bonnet: The assembly that connects the valve body to the actuator, providing a pressure boundary around the stem. Includes packing to prevent stem leakage.

3. Trim: The internal components that control flow and provide sealing:

* Closure Member: The part that moves to block flow (Ball, Gate, Disc/Plate).

* Seat(s): The precision-machined surfaces against which the closure member seals to achieve bubble-tight shutoff. Often resilient (elastomer like PTFE) or metal-to-metal. Critical for ESDV performance.

* Stem: Connects the actuator to the closure member, transmitting motion. Must withstand thrust/torque without bending or breaking.

4. Actuator: As described previously (Pneumatic Diaphragm, Hydraulic Piston, Scotch-Yoke, Rack & Pinion, Electric w/ Spring). Provides the force and motion.

5. Solenoid Valve(s): Electrically operated valves controlled by the SIS. They direct or vent the air/hydraulic pressure to/from the actuator to initiate opening or (crucially) closing. Redundant solenoids (2oo2, 2oo3 voting) are common for high SIL applications.

6. Limit Switches/Position Transmitters: Provide electrical feedback to the control system (DCS/SIS) confirming the valve’s actual position (Open, Closed, sometimes Intermediate). Vital for operator awareness and SIS diagnostics.

7. Local Position Indicator: A visual mechanical flag or pointer showing OPEN/CLOSED status at the valve site.

8. Manual Override: A mechanism (handwheel, lever, hydraulic hand pump) allowing operators to manually open or close the valve during maintenance or if the actuator fails. Does not bypass the automatic safety function.

9. Accessories (Often included): Air filter regulators (for pneumatic), quick exhaust valves (to speed closure), volume tanks (to store air for one-trip capability on loss of supply), lockout valves.

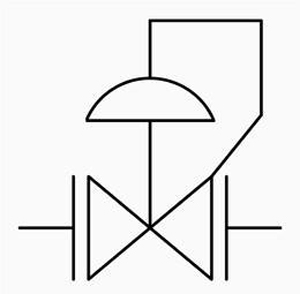

The Language of Diagrams: Shutdown Valve Symbols Recap & Standards

As covered in the P&ID section, the symbol clearly identifies an ESDV/SDV:

* Valve Type Symbol: Ball (Triangles + Circle), Gate (Sliding Rectangle), Butterfly (Line through Circle).

* Actuator Symbol: Solid or Hatched Square attached to the valve symbol.

* Labeling: ”ESD”, “SD”, or “XV” clearly marked on the actuator symbol.

* Fail Action: ”FC” (Fail Close – most common) or “FO” (Fail Open) indicated.

* SIS Link: Instrument bubble (e.g., Hexagon) connected by dashed line to actuator, containing the SIS tag number (e.g., ZV-1001).

Key Standards: ISA-5.1 (Instrumentation Symbols and Identification) is the primary standard in North America. ISO 14617 (Graphical symbols for diagrams) is used internationally. Consistency within a plant’s P&ID standards is paramount.

Emergency Shutdown Valve Symbol

Guardians of Hydrocarbons: Emergency Shutdown Valves in Oil and Gas

The oil and gas industry represents the most demanding and critical application area for ESDVs. The potential consequences of failure – massive fires, explosions, toxic releases, environmental disasters, and loss of life – are immense. ESDVs are ubiquitous throughout the value chain:

1. Upstream (Wellheads, Platforms, FPSOs):

* Wellhead ESDVs: Installed on Xmas trees (surface/subsea) to isolate individual wells in emergencies (e.g., blowout, fire). Subject to extreme pressures (HPHT wells). API 6A specification is common.

* Manifold/Pipeline ESDVs: Isolate sections of flowlines, gathering lines, or export pipelines on platforms or FPSOs. API 6D specification. Fire-safe design is mandatory.

* Process Train ESDVs: Isolate major equipment like separators, compressors, pumps in case of fire or failure.

2. Midstream (Pipelines, Pump/Compressor Stations):

* Block Valves (Often ESDVs): Installed at regular intervals along pipelines to isolate ruptured sections, minimizing spill volume. Remote actuation from control centers is standard. API 6D.

* Station ESDVs: Isolate pumps, compressors, meters, storage tanks within stations.

3. Downstream (Refineries, Petrochemical Plants, LNG Terminals):

* Unit Isolation ESDVs: Rapidly isolate entire processing units (e.g., Crude Distillation, FCCU, Hydrocracker) during major fires or catastrophic events.

* Equipment Protection ESDVs: Isolate furnaces, reactors, columns, large compressors.

* Loading/Unloading ESDVs: Isolate marine or railcar loading arms in emergencies.

Unique Oil & Gas Requirements:

* Stringent Standards: API standards dominate: API 6A (Wellhead), API 6D (Pipeline/General), API 607/6FA (Fire Test). ISO 10497 (Fire Test) is also used. SIL certification per IEC 61508/61511 is standard.

* Fire-Safe Design: ESDVs *must* maintain pressure integrity and internal/external leakage control during and after exposure to fire (typically 30 minutes @ 1400-1700°F). This dictates special stem packing, extended bonnets, graphite seals, and metal seat designs.

* Material Selection: Must handle sour service (H2S – NACE MR0175/ISO 15156), high pressures (HPHT), cryogenic temperatures (LNG), and corrosive fluids. Duplex stainless steels, Inconel, Monel are common.

* Robust Actuation: Hydraulic spring-return actuators are prevalent due to the high force requirements for large valves and high differential pressures, especially upstream. Redundant systems are common.

* Subsea ESDVs: Represent the pinnacle of reliability and technology, designed for extreme depths, pressures, and remote operation with no maintenance access. Redundancy and ultra-high reliability are paramount.

Conclusion: The Indispensable Barrier

Emergency Shutdown Valves are far more than just valves; they are the engineered guardians of industrial safety. Their fail-safe design, rapid action, high reliability, and critical role within Safety Instrumented Systems make them the last line of defense against catastrophic incidents. Understanding their function, components, working principle, and the stringent requirements placed upon them – especially in high-hazard industries like oil and gas – is essential for engineers, operators, and safety professionals. From the symbol on a P&ID to the massive valve on an offshore platform, the ESDV stands as a vital sentinel, constantly ready to act when every second counts, protecting people, the planet, and priceless assets. Proper specification, installation, rigorous testing (including PST and FST), and meticulous maintenance are non-negotiable to ensure these silent guardians perform their life-saving function flawlessly when called upon.

Post time: May-28-2025