At NSW Valve, we understand that precise flow control is the lifeblood of efficient industrial operations. Three-way valves are pivotal components in achieving this control, offering unmatched versatility in directing, mixing, and diverting process media. This definitive guide delves into the types, principles, and applications of these essential valves, providing the technical insight you need to optimize your systems.

What is a Three Way Valve?

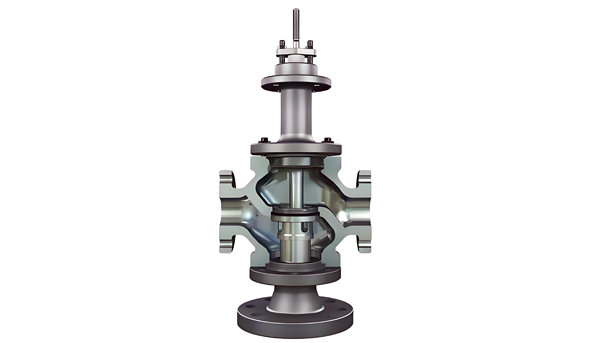

A Three Way Valve is a type of industrial valve featuring three ports within its body. These ports facilitate the connection of three separate pipelines, allowing the valve to manage the flow path between them. Unlike simple on/off valves, a three-way valve’s primary function is to change the direction of flow, mix flows from two sources, or split a single flow into two streams.

Common types found in industrial piping systems include Three Way Ball Valves, Three Way Control Valves (or regulating valves), and Three Way Globe Valves. Each type is engineered with distinct internal mechanisms—such as a rotating ball or a lifting stem—to achieve the desired flow control function, making them suitable for a wide array of applications from general plumbing to complex process automation.

How Does a Three Way Valve Work?

The operation of a three-way valve hinges on the movement of an internal component (like a ball, plug, or globe plug) relative to the valve seats. This movement alters the pathways between the three ports, effectively controlling the fluid direction. Based on their function, they are primarily categorized into two types:

Mixing Valve (Two Inlets, One Outlet)

This configuration has two inlet ports (e.g., A and B) and one common outlet port (C). The valve core’s position regulates the proportion of media entering from the two inlets, which is then mixed before being discharged from the outlet (C).

• Example: In HVAC systems, a Three Way Control Valve is frequently used to blend cold and hot water streams to achieve a precise output temperature for climate control39.

Diverting Valve (One Inlet, Two Outlets)

This configuration features one common inlet port (A) and two outlet ports (B and C). The valve core’s movement directs the incoming flow from the single inlet (A) to either one of the two outlets (B or C) or proportionally splits it between both.

• Example: In chemical processing, a diverting valve can distribute a raw material stream between two different reactor vessels or processing lines.

Key Functions of Three Way Valves

The core purpose of a three-way valve is to alter fluid flow paths through the movement of its internal mechanism. Its operation can be summarized in two main modes:

• Mixing (Combining Flow): Combining two incoming fluid streams into a single outlet. This is ideal for temperature regulation or precise chemical dosing scenarios where two media need to be combined.

• Diverting (Splitting Flow): Splitting a single incoming fluid stream between two outlets. This is commonly used for bypass control, system isolation, or process switching, ensuring continuous flow in a system during maintenance or operation changes.

Three Way Valves vs. Two Way Valves: A Fundamental Difference

The most apparent visual difference is the extra flow port. A standard two-way valve has one inlet and one outlet, functioning primarily as an on/off or simple throttling device for a single flow path.

A Three Way Valve, with its additional port (often called the diverting port C), is specifically designed to change flow direction. The basic operation involves media entering through port A. Depending on the valve’s position, flow is directed to either port B or port C. When the valve is closed, it can shut off flow entirely. This directional control capability is a function standard valves do not possess.

Types of Three Way Valves: A Detailed Classification

Three-way valves can be categorized based on their design, material, and operation method.

By Valve Design and Function

| Valve Type | Description | Common Applications |

|---|---|---|

| Three Way Ball Valve | Utilizes a rotating ball with an L-shaped or T-shaped bore. L-type valves are for flow diversion between two paths, while T-type valves can handle mixing, diverting, and flow switching1. | Quick on/off or flow diversion in general industrial services, water, oil. |

| Three Way Control Valve | Designed for precise modulation of flow, pressure, or temperature. Often features a plug and stem assembly for fine control and can be electric or pneumatic actuated. | Precise temperature control in heat exchangers, process flow regulation in chemical plants. |

| Three Way Plug Valve | Similar in function to a ball valve but uses a cylindrical or conical plug instead of a ball. Provides a tight seal and is often used for on/off and diverting services. | Handling of slurries or fluids with suspended solids. |

| Three Way Globe Valve | Features a globe-shaped body and a disc that moves perpendicular to the seat. Excellent for throttling and precise flow regulation, often used in a mixing application. | Steam, water, and chemical feed systems where precise mixing control is critical5. |

By Material of Construction

The choice of material is critical for compatibility with the process media, pressure, and temperature.

• Cast Iron: A cost-effective option for general-purpose applications with non-corrosive media like water.

• Stainless Steel (304/316): Offers excellent corrosion resistance, making it suitable for corrosive fluids, food and beverage, and pharmaceutical applications.

• Carbon Steel & Chrome-Molybdenum Steel: Ideal for high-pressure and high-temperature services, commonly found in power generation and hydrocarbon processing.

By Actuation Method

• Manual: Operated by a hand lever or gear. Suitable for applications where adjustment is infrequent.

• Pneumatic: Uses compressed air to actuate the valve. Offers fast response times, is explosion-proof, and is reliable for automated processes.

• Electric: Uses an electric motor to actuate the valve. Ideal for complex control schemes and when precise positioning is required.

Important Note: The actuators for Three Way Ball Valves, particularly pneumatic ones, are often designed for 180-degree rotation to accommodate the full range of motion needed for port switching, unlike the standard 90-degree rotation used for simple on/off two-way ball valves.

Industrial Applications of Three Way Valves

Three-way valves are indispensable across numerous industries due to their versatile flow control capabilities:

• HVAC Systems: Regulating the mixture of hot and cold water in heating and cooling coils to maintain precise building temperatures.

• Chemical and Petroleum Industries: Distributing raw materials to different reaction vessels, mixing various process streams, or diverting flow for batch processes.

• Food and Pharmaceutical Industries: Ensuring hygienic flow diversion, CIP (Cleaning-In-Place) routines, and precise control of ingredient mixing without cross-contamination.

• Water Treatment Systems: Managing flow paths for filter backwashing, directing water to different treatment stages, or controlling the injection of chemical additives.

• Steam and Power Systems: Diverting steam to different turbines or heat exchangers and managing condensate return lines.

Advantages and Disadvantages of Three Way Valves

Advantages:

• Flexible Flow Control: Enables complex functions like proportional mixing and flow splitting, replacing multiple two-way valves in some systems.

• Compact Design: Integrates the function of multiple valves into a single unit, saving space, reducing potential leak points, and often lowering overall installation costs.

• Automation Ready: Can be easily integrated with pneumatic or electric actuators for remote control and seamless incorporation into automated process loops.

• Excellent Sealing: Modern designs, especially Three Way Ball Valves, offer reliable sealing with soft or metal-seated options, achieving low leakage rates (e.g., ANSI Class IV/V/VI).

Disadvantages:

• Higher Flow Resistance: The internal geometry often creates more changes in flow direction, leading to a higher pressure drop compared to a straight-through two-way valve.

• Complex Maintenance: Internal components like seals and seats can be subject to wear and may require more specialized knowledge for maintenance and repair.

• Higher Initial Cost: The more complex design and manufacturing process typically result in a higher unit cost than standard two-way valves.

• Clogging Risk: Services with high viscosity or solid particle content can clog or erode the internal passages and sealing surfaces, requiring specialized valve designs.

How to Select the Right Three Way Valve: A Buyer’s Guide

Choosing the correct valve is critical for system performance and longevity. Consider these factors:

1. Media Properties: Identify the fluid’s corrosiveness, temperature, pressure, and whether it contains abrasives or solids. This dictates material selection (e.g., stainless steel for corrosive media).

2. Flow Characteristics: Determine the required flow capacity (Cv) and whether you need linear or equal percentage flow characteristics for precise control.

3. Connection Type: Choose between flanged (for high-pressure, permanent installations), threaded (for smaller lines), or welded connections (for high-integrity, leak-free services).

4. Actuator Type: Decide between manual, pneumatic (for fast, explosion-proof operation), or electric (for precise positioning and complex control) actuation based on your automation needs.

5. Brand and Certification: Partner with reputable manufacturers like NSW Valve that adhere to international quality standards (ISO 9001) and hold relevant API, CE, or other industry-specific certifications to ensure product reliability and safety.

Maintenance Best Practices for Three Way Valves

Proper maintenance ensures optimal performance and extends service life.

Routine Inspection

• Leak Checks: Regularly inspect stem seals, body gaskets, and port connections for any signs of external leakage.

• Operation Test: Cycle the valve manually or automatically to ensure smooth operation without sticking or binding.

• Temperature Monitoring: In high-temperature services, monitor the valve body temperature to detect potential issues like internal blockage or packing failure.

Cleaning and Lubrication

• Internal Cleaning: Periodically flush the valve internals with clean water or air to remove sediment or debris that could cause wear or clogging.

• Stem Lubrication: For manual and some automated valves, lubricate the stem threads periodically with a suitable high-temperature grease.

• Seal Replacement: Replace soft seals promptly when wear or aging is detected. Metal sealing surfaces can sometimes be lapped or refinished.

Calibration and Testing

• Flow Calibration: For control valves, verify and calibrate the relationship between the actuator position and the resulting flow rate using a flow meter.

• Leakage Test: Isolate the valve and hydrostatically test it at 1.5 times its rated working pressure to check for internal and external leaks, following industry standard procedures.

Troubleshooting Common Issues

• Internal Leakage: Often caused by worn or damaged seat seals. Inspect, clean, or replace the seats and the ball/plug.

• External Leakage: Typically stems from damaged stem packing or loose body bolts. Repack the gland or tighten bolts to the specified torque.

• Actuation Failure: Check the power supply to electric actuators or the air supply pressure and quality for pneumatic actuators. Inspect mechanical linkages for damage or obstruction.

• Maintenance Logging: Maintain detailed records of all maintenance activities, including dates, findings, and parts replaced. This history is invaluable for predicting failures and planning outages.

Post time: Aug-26-2025