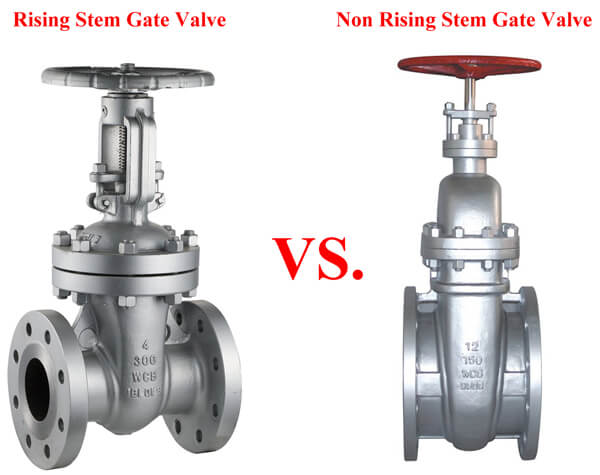

Rising Stem vs Non Rising Stem Gate Valve: Critical Differences & Industrial Applications

Classifying Gate Valve Designs

Gate valves are categorized by stem design: Rising Stem Gate Valves (OS&Y) and Non Rising Stem Gate Valves. Each type offers distinct structural advantages for industrial flow control.

What is a Rising Stem Gate Valve

Rising stem designs position the stem nut above the valve body. Rotating the stem nut lifts/lowers the gate, providing:

Visual Position Indicators: Stem height shows real-time open/close status.

Easy Maintenance: Exposed threads enable lubrication (extending lifespan).

High Durability: Stem avoids fluid contact, ideal for corrosive media (e.g., oil, chemicals).

Applications: Petrochemical plants, water treatment, above-ground installations.

What is a Non Rising Stem Gate Valve

Non rising stems feature an internal stem nut within the valve body. Rotation moves the gate while the stem remains fixed:

Space Efficiency: Compact height (saves 30–50% vertical space vs. rising stems).

Corrosion Resistance: Sealed design protects against dust/erosion.

Installation Flexibility: Perfect for tight spaces (e.g., pipelines, ships, municipal systems).

Note: Internal threads require periodic lubrication; opening indicators are essential.

Key Differences: Rising Stem vs Non Rising Stem Gate Valves

| Feature | Rising Stem Gate Valve | Non Rising Stem Gate Valve |

|---|---|---|

| Design | Exposed trapezoidal threads | Internal stem threads |

| Stem Movement | Vertical lift with gate | Rotates in place |

| Space Requirement | High (1.2x valve diameter) | Compact |

| Maintenance | Easy lubrication & inspection | Complex; requires disassembly |

| Lifespan (Cycles) | 100,000+ | ~50,000 |

| Best For | Frequent operation, high corrosion | Space-constrained, buried systems |

Performance & Selection Guidelines

1. Space Constraints

Non rising stem valves reduce height by 30–50% for valves >DN300.

2. Medium Compatibility

Corrosive fluids? Choose rising stem valves with SS316L stems (40%+ corrosion resistance).

3. Operational Frequency

Rising stems endure 2x more cycles (100k vs. 50k).

4. Specialized Design

- Non Rising with Diversion Holes: Reduces water hammer (15–20% pressure loss drop).

- Elastic Seal Rising Stems: PTFE seals achieve ANSI Class VI leakage standards for gas systems.

5. Standards Compliance:

- Rising stems: API 600 (stem tensile strength ≥483 MPa).

- Non rising stems: ISO 7-1 thread seal testing.

Conclusion: Matching Valve to Application

Rising stem gate valves prioritize maintenance access and visual feedback, while non rising stem valves excel in confined spaces. Engineers must weigh:

- Maintenance Needs (rising stem advantage)

- Installation Space (non rising stem advantage)

- Media & Operational Demands

Optimize flow control systems today by selecting the ideal gate valve design for your industrial environment.

Post time: Jun-30-2025