In the world of industrial fluid control, efficiency, reliability, and safety are paramount. Among the various devices engineered for this purpose, the quarter turn ball valve stands out as a cornerstone of modern piping systems. This comprehensive guide will delve deep into what makes these valves so effective, exploring their operation, types, and critical selection criteria, empowering you to make the best choice for your specific needs.

Understanding Fluid Control and Its Importance

Fluid control is the practice of managing the flow rate, pressure, and direction of liquids and gases within a system. Precise control is vital across countless industries—from oil and gas to pharmaceuticals and food processing. It ensures operational safety, process efficiency, product quality, and environmental protection. The choice of valve, the primary component in this control loop, directly impacts the entire system’s performance and longevity.

What Valves Are Included in Quarter Turn Valves?

As the name suggests, quarter turn valves require only a 90-degree turn of the actuator to move from fully open to fully closed. This family of valves is renowned for its simplicity and speed of operation. The main types include:

Ball Valves

The most common type, using a rotating ball with a bore to control flow. They offer excellent shut-off capability and are versatile for a wide range of pressures and temperatures.

Butterfly Valves

Featuring a disc that rotates on a central axis, these valves are compact, lightweight, and cost-effective for large-diameter, low-pressure applications.

Plug Valves

Similar in operation to ball valves but using a cylindrical or conical plug instead of a ball. They are robust and well-suited for handling slurries and abrasive media.

How Quarter Turn Ball Valves Work

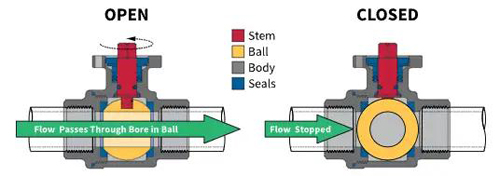

The operation of a quarter turn ball valve is elegantly simple. The valve’s core is a spherical ball with a hole (bore) through its center. This ball is seated within a valve body and connected to an external handle or actuator via a stem.

* Open Position: When the handle is turned 90 degrees, the ball rotates so that the bore aligns with the pipeline, allowing fluid to flow through with minimal resistance.

* Closed Position: Turning the handle back 90 degrees positions the bore perpendicular to the flow, blocking it completely. The ball is sealed against flexible seats (often made from PTFE or other polymers), ensuring a tight, bubble-proof shut-off.

This simple on/off mechanism makes them incredibly fast-acting and reliable.

Types of Quarter Turn Ball Valves

Quarter turn ball valves can be categorized based on material, connection type, and body structure to suit every conceivable application.

Classification by Material

Stainless Steel

Offers excellent corrosion resistance and strength, ideal for chemical, food, and marine applications. Grades like CF8M (F316) are common.

Carbon Steel

Known for high strength and durability, perfect for high-pressure and high-temperature services in oil, gas, and power generation (e.g., ASTM A182 A105, ASTM A216 WCB).

Ductile Iron

A strong, economical choice with good mechanical properties for water, oil, and gas applications in medium pressure ranges.

Bronze (B62) & C95800 Ball Valve

Excellent for seawater, steam, and oil applications due to superior corrosion resistance and anti-galling properties.

Duplex Stainless Steel

Provides exceptionally high strength and outstanding resistance to chloride stress corrosion cracking, used in demanding offshore and chemical environments.

Classification by Connection Type

Flanged Ball Valve

Features flanges that bolt to matching pipe flanges. Ideal for easy installation, maintenance, and high-pressure applications.

Threaded Ball Valve (NPT)

Connects to pipes using male or female NPT threads. A compact and cost-effective solution for smaller line sizes.

Wafer Ball Valve

Sandwiched between two pipe flanges. Lighter and more compact than flanged valves but not suitable for isolation without downstream support.

Welded Ball Valve (SW, BW)

Socket Weld (SW) or Butt Weld (BW) ends provide a permanent, strong, and leak-free connection, essential for high-integrity services in refineries and chemical plants.

Classification by Body Structure

2-Piece Ball Valve

The most common design. It has two main parts screwed together. Maintenance often requires removal from the line.

3-Piece Ball Valve

The valve body has three parts, with the end caps bolted on. The main advantage is that the valve can be serviced in-line without removing it from the pipeline.

Floating Ball Valve

The ball is not fixed and is held in place by the valve seats. Line pressure pushes the ball against the seat to enhance sealing. Standard for smaller bore valves.

Trunnion Mounted Ball Valve

The ball is anchored on a trunnion, reducing operating torque. This design is essential for large bore and high-pressure applications.

Top Entry Ball Valve

The valve body is one piece, and all internal components are inserted and serviced through the top. This allows for easy in-line maintenance without disturbing the pipework.

Quarter Turn Valves vs. Sliding-Stroke Valves

This is a fundamental distinction in valve technology.

Difference in Valve Types

Quarter Turn Valves:

Include Ball Valves, Plug Valves, and Butterfly Valves. Operation is based on a rotating motion.

Sliding-Stroke Valves (Multi-Turn Valves):

Include Gate Valves and Globe Valves. Operation is based on a linear motion, requiring multiple turns of a handwheel to open or close.

Difference in Actuator Requirements

The operating motion dictates the type of actuator needed.

Actuators for Quarter Turn Valves:

Rack-and-pinion pneumatic actuators, scotch yoke (vane-type) pneumatic actuators, levers, and gear operators. These are designed to provide efficient 90-degree rotation.

Actuators for Sliding-Stroke Valves:

Piston-style pneumatic actuators, diaphragm actuators, handwheels, and bevel gear operators. These are designed to provide the multi-turn linear thrust required.

Difference in Application

* Quarter Turn Valves: Best for on/off and diverting services. They are fast-acting, offer tight sealing, and have low pressure drop. Not ideal for precise throttling.

* Sliding-Stroke Valves:

* Gate Valves: Used purely for on/off service in fully open or closed positions.

* Globe Valves: Excellent for throttling flow and regulating pressure but have a higher pressure drop.

Advantages of Using Quarter Turn Ball Valves

* Rapid Operation: Full open/close in just a 90-degree turn.

* Excellent Sealing: Provides bubble-tight shut-off, minimizing leakage.

* Low Maintenance: Simple design with few moving parts.

* Versatility: Available in a vast range of materials, sizes, and pressure classes.

* High Flow Capacity: The full bore design offers minimal flow resistance (Cv value).

* Durability: Robust construction ensures a long service life, even in harsh conditions.

Applications of Quarter Turn Ball Valves in Various Industries

The versatility of quarter turn ball valves makes them indispensable across industries:

* Oil & Gas: Wellheads, pipelines, and refining processes.

* Chemical Processing: Handling corrosive and aggressive media.

* Power Generation: Steam, water, and coolant lines.

* Water & Wastewater: Treatment and distribution systems.

* Marine & Offshore: Seawater systems and fuel handling.

* Pharmaceuticals & Food: Hygienic processes requiring cleanability.

Key Factors to Consider When Selecting a Quarter Turn Ball Valve

Choosing the right valve is critical. Consider these factors:

1. Media: What fluid is being controlled? (Corrosiveness, abrasiveness, viscosity)

2. Pressure & Temperature: What are the operating and maximum PSI/Bar and °F/°C?

3. Material Compatibility: Does the valve body, ball, and seat material suit the media and environment?

4. Connection Type: How will it be installed? (Flanged, threaded, welded)

5. Valve Size: What is the required pipe diameter (NPS/DN)?

6. Function: Is it for on/off, diverting, or limited throttling?

7. Standards & Certifications: Are specific approvals needed? (e.g., API 6D, ISO 15848, TA-Luft, FDA)

Maintenance and Troubleshooting Tips for Quarter Turn Ball Valves

* Regular Inspection: Check for external leaks, corrosion, and operability.

* Cycle the Valve: Periodically operate valves that are normally left in one position to prevent seizing.

* Common Issues:

* Leakage: Often caused by damaged seats or seals. May require disassembly and replacement.

* Hard to Operate: Can be due to internal corrosion, seized stem, or lack of lubrication. Do not force it; investigate the cause.

Innovations and Trends in Valve Technology

The valve industry is evolving with a focus on:

* Smart Valves: Integration with IIoT (Industrial Internet of Things) for real-time monitoring of position, pressure, temperature, and predictive maintenance.

* Advanced Materials: Development of new alloys and polymers for higher corrosion resistance and longer life in extreme conditions.

* Fugitive Emissions Control: Enhanced stem sealing technology (like live-loading) to meet stricter environmental regulations.

* 3D Printing: Rapid prototyping and manufacturing of complex valve components for custom solutions.

Conclusion: Choosing the Right Quarter Turn Ball Valve for Your Needs

Selecting the optimal quarter turn ball valve is a complex decision that balances technical requirements, operational demands, and total cost of ownership. Understanding the principles, types, and selection criteria outlined in this guide is the first step toward ensuring system reliability and efficiency.

For applications where performance cannot be compromised, partnering with an expert manufacturer is key. At NSW Valve, we combine engineering expertise with stringent quality control to deliver valves that meet the highest standards. Our products are backed by full material traceability and rigorous testing.

Ready to find the perfect valve solution for your project?

Explore our range of high-performance quarter turn ball valves or contact our engineering team today for a consultation.

Post time: Sep-04-2025