Butterfly valves are essential components in various industrial applications, known for their efficiency and reliability in regulating flow. One critical aspect that significantly impacts their performance and suitability is the end connection type. Understanding the differences between lug, wafer, and flange end connections is vital for selecting the right valve for your system. This article delves into the specifics of each connection type, their comparisons, and guidelines for optimal selection.

What is End Connection of Butterfly Valve

The end connection of a butterfly valve refers to the method by which the valve is attached to the piping system. This connection is crucial as it ensures a secure, leak-proof seal and affects the valve’s installation, maintenance, and overall functionality. The right end connection enhances system integrity, while an inappropriate choice can lead to leaks, inefficiencies, or even system failure.

Type of Butterfly Valve End Connection (Lug, Wafer, Flange)

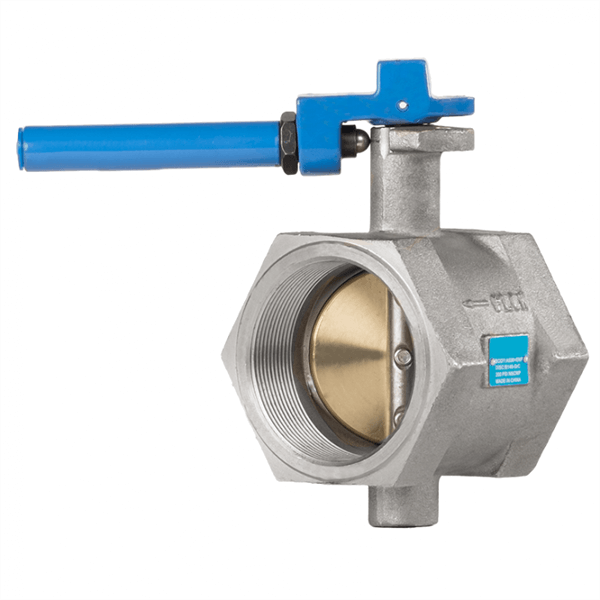

What is Lug Butterfly Valve

A Lug Butterfly Valve features threaded lugs (ears) on both sides of the valve body. These lugs have holes that align with bolts, allowing the valve to be installed between two flanges without nuts on both sides. This design enables the valve to be mounted securely and is particularly useful in systems where one side of the pipeline may need to be disconnected without affecting the other.

What is Wafer Butterfly Valve

A Wafer Butterfly Valve is designed to be lightweight and compact. It fits between two flanges and is secured using long bolts that pass through the entire valve and flanges. Unlike lug valves, wafer valves do not have threaded lugs; instead, they rely on the flange bolts for compression and sealing. This makes them cost-effective and ideal for space-constrained applications.

What is Flange Butterfly Valve

A Flange Butterfly Valve has flanges integrated into the valve body. These flanges match the piping flanges and are bolted together directly. This type offers a robust and durable connection, suitable for high-pressure and high-temperature applications. The flanged end provides excellent sealing and is often used in demanding industrial environments.

Other End Connection Butterfly Valve

Welded Butterfly Valve

Welded end butterfly valves are directly welded to the pipeline, providing a permanent and leak-proof connection. They are ideal for high-pressure and high-temperature systems where disassembly is not required.

Clamp Butterfly Valve

Clamp end valves use clamps for quick installation and removal, commonly used in sanitary applications such as food, beverage, and pharmaceutical industries.

Threaded Butterfly Valve

Threaded end valves have male or female threads for direct screwing into the pipeline. They are suitable for low-pressure and small-diameter systems.

Lug Butterfly Valve vs. Wafer vs. Flange

Wafer vs. Lug Butterfly Valve

Wafer Butterfly Valves are lighter and more economical, ideal for space-saving applications. They depend on flange bolts for compression, making them less suitable for end-of-line services. Lug Butterfly Valves, with their threaded lugs, offer better support and are suitable for end-of-line applications where one side may be disconnected.

Flange vs. Lug Butterfly Valve

Flange Butterfly Valves provide a stronger, more durable connection, suitable for high-pressure systems. They are heavier and more expensive. Lug Butterfly Valves are easier to install and remove, offering flexibility for maintenance but are generally used in medium-pressure applications.

Flange vs. Wafer Butterfly Valve

Flange Butterfly Valves are robust and ideal for harsh conditions, offering superior sealing and stability. Wafer Butterfly Valves are compact and cost-effective, best for low to medium-pressure systems where space and budget are constraints.

The Importance of Correctly Selecting Butterfly Valve Connections

Choosing the right butterfly valve connection is crucial for system efficiency, safety, and longevity. An incorrect selection can lead to leaks, pressure drops, increased maintenance costs, and potential system failures. Factors such as pressure, temperature, fluid type, and installation environment must be considered.

When to choose a lug butterfly valve

Opt for a lug butterfly valve in applications requiring end-of-line service or where disconnection of one pipe section is necessary without disturbing the other. They are suitable for moderate pressure and temperature conditions.

When to choose a wafer butterfly valve

Select a wafer butterfly valve for cost-sensitive, space-constrained applications with low to medium pressure. They are ideal for systems where the valve is centered between two flanges and disassembly is infrequent.

When to choose a flange butterfly valve

Use a flange butterfly valve in high-pressure, high-temperature, or corrosive environments. They are perfect for permanent installations requiring robust sealing and durability, such as in chemical processing or water treatment plants.

Tip:

1. Butterfly valves larger than DN600, we recommend flanged butterfly valves.

The larger the valve, the heavier it is, and flanged butterfly valves require more bolts to secure them to the pipe. Therefore, flanged connections provide a more secure installation for large-diameter butterfly valves.

2. For butterfly valves smaller than DN200, we recommend wafer-type butterfly valves.

Wafer-type butterfly valves can be installed with flanges, wafers, or lugs, but wafer-type butterfly valves are less expensive than flanged and lug-type butterfly valves.

Work Conditions of Lug, Flange, Wafer Butterfly Valve

• Lug Butterfly Valve: Best for moderate pressure and temperature, ideal for water, air, and gas applications. Common in HVAC, fire protection, and general industrial systems.

• Wafer Butterfly Valve: Suitable for low to medium pressure and temperature, widely used in water distribution, HVAC, and light industrial processes.

• Flange Butterfly Valve: Designed for high pressure and temperature, excellent for harsh chemicals, steam, and heavy-duty industrial applications.

Summary

Selecting the appropriate butterfly valve connection—lug, wafer, or flange—is critical for optimal system performance. Lug valves offer flexibility for end-of-line services, wafer valves provide cost-effective solutions for space-limited applications, and flange valves deliver robustness for demanding conditions. Understanding your system requirements and the unique advantages of each connection type ensures reliability, efficiency, and longevity. For high-quality butterfly valves tailored to your needs, explore the range at www.nswvalve.com.

Post time: Sep-11-2025