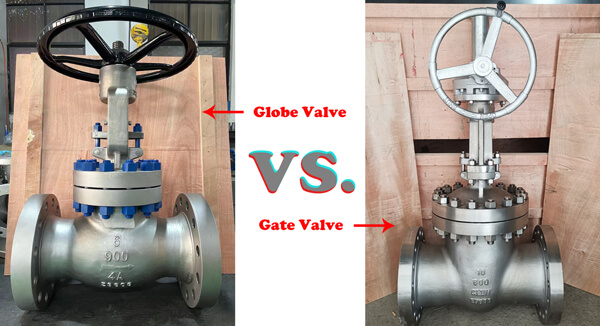

Gate Valve vs Globe Valve: Key Differences, Applications, and Identification

Industrial pipelines rely on precise flow control, making valve selection critical. Two fundamental types—gate valves and globe valves—serve distinct purposes despite visual similarities. This guide clarifies their differences, uses, and identification methods.

What is a Gate Valve

A gate valve controls flow by raising or lowering a rectangular or wedge-shaped “gate” via a threaded stem. Key features:

Operation: Fully open/closed only; unsuitable for throttling.

Flow Path: Straight-through design minimizes pressure drop.

Sealing: Tight shutoff when fully closed, with low leakage risk.

Applications: Petrochemicals, water supply, large-diameter pipelines where minimal flow resistance is essential.

Example: In municipal water systems, gate valves isolate sections during maintenance due to their zero-flow-resistance when open.

What is a Globe Valve

A globe valve (or stop valve) regulates flow using a disc or plug that presses vertically onto a seat. Key features:

Operation: Designed for throttling and frequent operation.

Flow Path: S-shaped circuit increases resistance but enables precise control.

Sealing: Forced-sealing mechanism requires higher closing force.

Applications: Boilers, HVAC, steam systems—any scenario requiring flow adjustment.

Example: Globe valves manage steam flow in power plants, allowing operators to fine-tune pressure.

Key Differences: Gate Valve vs Globe Valve

| Aspect | Gate Valve | Globe Valve |

|---|---|---|

| Structure | Straight flow path; gate rises vertically | S-flow path; disc moves perpendicular to seat |

| Function | On/off only; no throttling | Throttling and on/off |

| Flow Resistance | Very low (when fully open) | High (due to directional changes) |

| Stem Height | Taller (rising-stem design) | Compact |

| Installation | Bidirectional flow | Directional (arrow indicates flow path) |

How to Identify Gate Valves & Globe Valves

1. Visual Inspection:

Gate Valve: Tall body (especially rising-stem types); handwheel lifts as valve opens.

Globe Valve: Spherical body; shorter stem height.

2. Flow Direction:

Gate valves allow bidirectional flow.

Globe valves have directional arrows cast on the body.

3. Handwheel Operation:

Gate valves require multiple rotations to open/close.

Globe valves open/close faster (shorter stem travel).

When to Use Each Valve

Choose Gate Valves For:

1. Full-flow isolation in water/oil pipelines.

2. Low-pressure-drop systems (e.g., long-distance transport).

3. Infrequent operation (e.g., emergency shutoffs).

Choose Globe Valves For:

1. Flow regulation (e.g., cooling systems).

2. Frequent operation (e.g., daily adjustments).

3. High-pressure steam/gas applications.

Why Valve Choice Matters

Selecting the wrong valve risks system inefficiency or failure. Gate valves maximize flow in open positions but leak if partially closed. Globe valves offer control but increase energy costs due to resistance. Always match valve type to operational demands—ensuring safety, longevity, and peak performance.

Pro Tip: For high-pressure systems, combine gate valves (main isolation) with globe valves (precision control) for optimal results.

Post time: Jun-21-2025