Gate Valve Packing refers to the filling material installed in the sealing part of the gate valve, which is mainly used to ensure the sealing performance of the valve and prevent medium leakage. There are various types of packing, and the common ones are Flexible Graphite, PTFE, Bellows Sealing Packing, Low Fugitive Emission Packing and other Packing Materials.

Storage Method of Valve Packing

The fillers of this project mainly consist of the following two materials: PTFE and soft graphite.

When stored, sealed in a bag or box. Store neatly in a dry and ventilated warehouse, avoid sunlight. Pay attention to ventilation during long-term storage, and control the temperature of the storage point not to exceed 50°C to prevent excessive dust. If the dust attached to the surface of the filler is removed and used, wipe it with a clean cloth.

Valve Packing Replacement Method

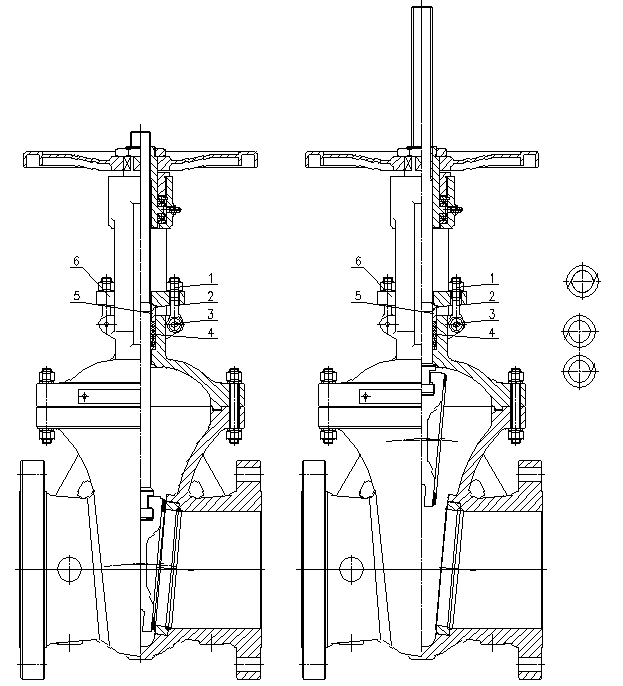

The packing seals are composed as follows:

- Packing compression nut

- Swing bolt

- Fixed pin

- Packing

- Packing sleeve

- Packing pressure plate

Sometimes 5 and 6 are integral parts according to the mold and Determined by different working conditions, the overall function is the same as that of the split

The packing seal replacement steps are as follows:

1. Use a wrench to remove 1) the packing compression nut and raise it 5) the packing press sleeve and 6) the packing press plate, leaving a space for the operation of replacing the packing.

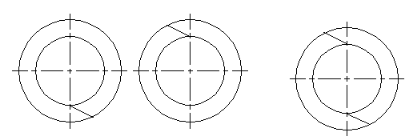

2. Use a flat-blade screwdriver or other strip metal pieces to remove the original packing and replace it with a new one. If packing packing is used, when installing the new packing, pay attention that the direction of the packing cuts should be staggered by 90~180°, and the included angle should be repeated in pairs. Do not have multiple overlaps in the same direction as shown in the figure;

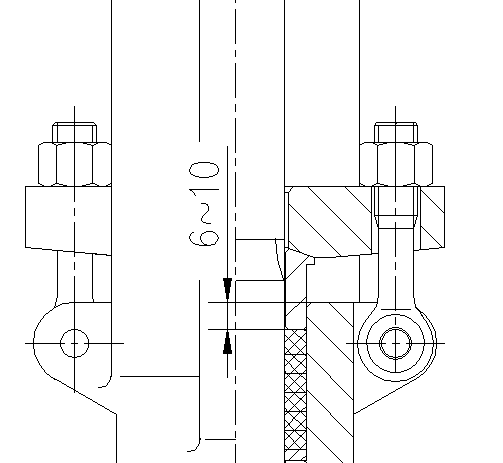

3. After installing an appropriate amount of packing, restore 5) packing gland and 6) packing pressure plate installation. When installing, pay attention to the position of the packing seal and 6~10mm deep into the valve cover (or 1.5~2 times the packing thickness) as the positioning reference ( As shown below).

4. Restore 1). Packing compression nut, 2) Tighten the installation position of the joint bolt until it reaches 20% of the packing compression.

5. After completing the above steps, perform key inspections on the valve that has replaced the packing in the next use to see if it is necessary to increase the preload of the packing.

Remarks: Instructions on re-tightening and replacement of packing under pressure.

Safety Precautions

The following operations are dangerous operations. Please do not try them lightly if they are not necessary. Please strictly follow this guidance document during the operation steps:

1. The operator should have a certain understanding of machinery and valves. In addition to the required mechanical tools, the operator must wear heat-insulating gloves, face shields, and helmets.

2. The valve is fully opened until the upper seal of the valve is fully effective. The judgment basis is that the valve operating mechanism can no longer lift the valve stem, and there is no abnormal sound at the valve stem.

3. The operator should be on the side of the packing seal position or other positions that cannot be projected. It is strictly forbidden to face the packing position. When the packing needs to be tightened, use a wrench to tighten 1) Packing compression nut, 2~4 teeth, both sides of the packing compression nut It needs to be executed, not just one side.

4. When the packing needs to be replaced, use a wrench to loosen 1) Packing compression nut, 2~4 teeth, the packing compression nut on both sides needs to be executed alternately. During this period, if there is an abnormal response from the valve stem, immediately stop and reset the nut, continue Operate the valve operating mechanism in accordance with the procedure in step 2, complete the seal on the valve stem until it is fully effective, and continue to replace the packing. The replacement packing under pressure is not allowed to be completely replaced except for special circumstances. The replacement quantity is 1/3 of the total packing. If it is impossible to judge, the top three packings can be replaced. After the installation is complete, restore the installation of 5 packing press sleeve and 6 packing press plate. When installing, pay attention to the position of the packing seal and 6~10mm deep into the valve cover (or 1.5~2 times the thickness of the packing) as the positioning reference. Restore 1). Packing compression nut, 2) Tighten the installation position of the joint bolt to 25% of the maximum compression of the packing. If there is no leakage in the bottom valve stem packing, it is complete. If there is leakage, follow the procedures in steps 2 and 3 to tighten.

5. All the above operation steps are only for rising stem lift valves such as: rising stem gate valve, rising stem stop valve, etc., not applicable to dark stem and non-lifting stem valves such as: dark stem gate valve, dark stem stop valve, butterfly valve, Ball valves and so on.

Post time: Jun-30-2021