Introduction: Why API 598 Matters

Valve reliability one place you can’t compromise Whether dealing with oil, gas or petrochemicals, industry demands make the highest demands of your valves. API 598 Valve Inspection and Testing is the industry’s de facto standard for establishing valve structural and pressure boundary integrity and for determining a valve’s ability to comply with a code’s allowable leakage rate. This specification establishes consistent criteria for Inspectors to determine quality, and a system to trigger re-inspection (or other remedial action) when attributes do become suspect.

What is API 598

Published by the American Petroleum Institute (API), API 598 specifies mandatory pre-shipment inspection and pressure testing protocols for metal valves used in hydrocarbon industries.

Key Objectives

• Verify structural strength (pressure holding)

• Validation of sealing performance (internal/external leakage)

• Standardize acceptance criteria globally

Critical Importance

• For Inspectors: Provides test methods that can be enforced

• For Buyers: It is the basis of purchase requirements and legal compliance

API 598 Testing Procedures: Step-by-Step Compliance

1. Scope & Referenced Standards

Specification for Steel Gate Valves Flanged or Butt Welding Ends, Bolted Bonnets. 34, etc.).

2. Inspection Requirements

• Responsibility: Manufacturer-led

• Key Checks:

→ Material certification

→ Dimensional accuracy

→ NDT (RT/UT/MT/PT to A519M)

→ Visual defects

→ Marking/nameplate compliance

→ Coating integrity

3. Pressure Testing (Critical Section)

Test Types & Procedures

| Test Type | Purpose | Valve State | Medium | Pressure | Duration (min) |

|---|---|---|---|---|---|

| Shell Test | Body/Bonnet | Open | Water | 1.5x MAWP @ 38°C (100°F) | ≥NPS 2: 60s |

| Backseat Test | The Backside Stem Bonnet Seal (If Used) | Open | Water/Gas (Low) | 1.1x MAWP @ 38°C (100°F) | = Shell Test |

| High Pressure Seat Test | Primary Sealing Closure | Closed | Water (Liquid valves) | 1.1x MAWP @ 38°C (100°F) | NPS 4+: 60s |

| Low Pressure Seat Test | Gas sealing verification | Closed | Air/Nitrogen | 0.5–0.7 MPa (6–8 bar) | = High-Pressure |

| DBB Test | Dual Isolation & Bleed function | Closed | Water/Gas | Per Seat Test | Per Seat Test |

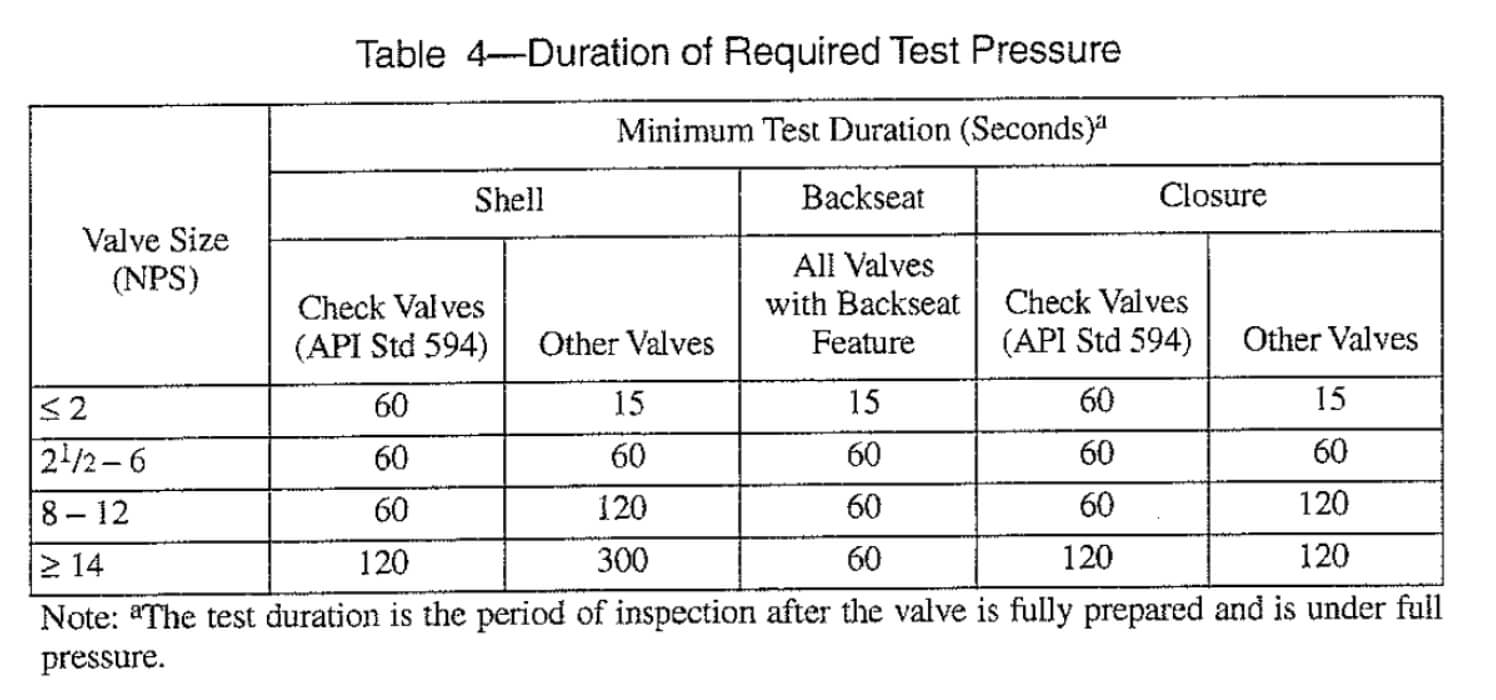

Required Test Pressure Duration – From API 598 Table 4

Leakage Acceptance Criteria

• Shell/Backseat Tests: Zero visible leakage

• High-Pressure Liquid Test (Metal Seat): No visible droplets

• Gas Test Bubble Rates (in bubbles per minute):

| Valve Type | Size (NPS) | Max Bubbles/min |

|---|---|---|

| Gate/Globe/Ball | ≤2.5 | 0 |

| 3–6 | 12 | |

| ≥8 | 20 | |

| Butterfly (Metal) | ≤2.5 | 0 |

| 3–6 | 24 | |

| ≥8 | 40 | |

| All Soft Seats | Any | 0 |

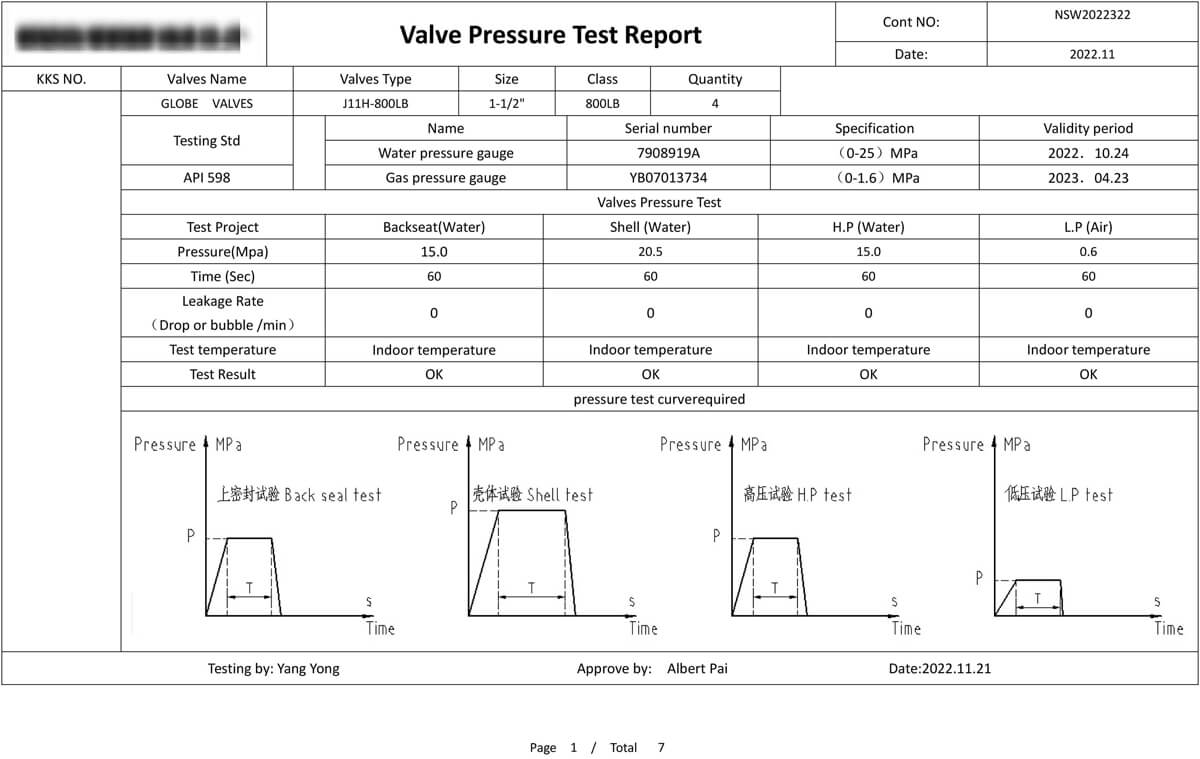

Sample Report of Valve Pressure Test

4. Post-Test Handling

Compulsory drying (vital to stainless steel) and re-preservation.

5. Certification

Compliance valves comes with API monogram (if required) and test reports.

Valves Covered by API 598

For metal valves with a manufacture to:

√ API 6D: Line Pipe Valves (Ball/Gate/Plug/Check)

√ API 6A: Wellhead Valves

√ API 600/602/603: Steel Gate Valves

√ API 608: Metal Ball Valves

√ API 609: Butterfly Valves

√ API 623: Steel Globe Valves

Key Point: API 598 is a test standard. Valve designs/materials are specified by product standards (API 6D and the like). Contracts must reference BOTH.

Practical Guidance for Professionals

For Inspectors

1. Latest API 598 edition mastered + product standards.

2. Quarterly, Before testing is conducted, calibrate test equipment (gauges, etc>).

3. Document bubble counts/photograph leaks

4. Enforce safety during gas tests

For Procurement Teams

1. Include in contracts: Rely on a witnessed Factory Acceptance Test (FAT)

• “Valves to be tested in accordance with API 598, 11th Ed (latest)”

• Applicable product specification (e.g., API 6D 25th Ed.)

2. Demand original signed test reports

3. Include supplementary requirements:

• Fire testing (API 607/6FA)

• Fugitive emissions (ISO 15848)

Conclusion: The Quality Imperative

API 598 is not just a standard—it is your first line of defense against failures involving valves. For inspectors, it is the definitive playbook. For procurement, it’s risk mitigation incarnate. In increasingly severe service conditions, strict adherence to API 598 is not an option-businesses demand it for safety, environmental responsibility, and reliability.

Post time: Jul-22-2025