What Is an API 609 Butterfly Valve

API 609 Butterfly Valves are industrial valves designed to American Petroleum Institute (API) standards. They deliver exceptional sealing, corrosion resistance, and pressure reliability in oil, gas, chemical, and petrochemical pipelines. These high-performance butterfly valves meet rigorous international benchmarks for safety and efficiency.

Understanding API 609 Standards

API 609 is the design standard for American standard butterfly valves issued by the American Petroleum Institute. Its full name is “Butterfly Valves: Double Flanged, Lug- and Wafer- Type“. The latest version is currently the 2021 version.

The latest standard version of API 609 is API 609-2021 (8th Edition), which updates the butterfly valve design standards, expands the specifications for double flange, lug and wafer butterfly valves, and adds clauses for butt-weld butterfly valves.

Standard update content

• Butt weld butterfly valve: The 2021 version adds design requirements for butt-weld butterfly valves on the original basis, further enriching the standard specifications for butterfly valve connection methods.

• Technical terms adjustment: Some technical specifications have been optimized according to industry practices, but the specific technical details are not disclosed in detail in public information.

Main contents of API 609 standard covers double-flanged, lug-type, and wafer butterfly valve designs. This standard defines:

1. Design Requirements: Fluid dynamics optimization for minimal flow resistance and precise control.

2. Material & Manufacturing: Specifications for valve bodies, discs (butterfly plates), stems, and seals.

3. Testing Protocols: Mandatory pressure, sealing, and flow tests for quality assurance.

4. Maintenance Guidelines: Procedures for inspection, lubrication, and repair.

How Butterfly Valves Work

A butterfly valve’s disc rotates 90° around its axis to regulate flow. Key characteristics:

• Open Position: Disc parallel to flow (minimal pressure drop).

• Closed Position: Disc perpendicular to flow (bubble-tight shutoff).

• Actuation: Uses manual handles, gear operators, or automated systems (pneumatic/electric).

Core Components of Butterfly Valves

1. Valve Body

Compact cylindrical design; available in wafer, lug, or flanged styles.

2. Disc (Plate)

Thin, circular plate (stainless steel common) for flow control.

3. Stem

High-strength shaft linking disc to actuator.

4. Seat Ring (Sealing)

EPDM, PTFE, or metal seats for zero-leakage performance.

5. Actuator

Manual, pneumatic, hydraulic, or electric drives.

Types of Butterfly Valves

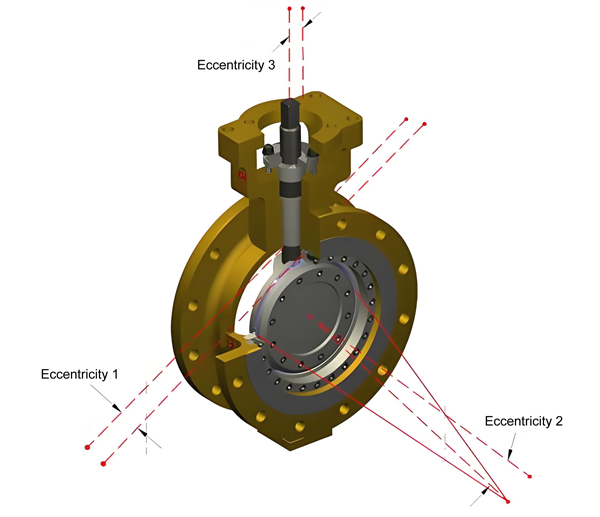

By Eccentricity

Concentric Butterfly Valve: Low-pressure water/air.

Single Eccentric Butterfly Valve: Reduced friction; ideal for food/pharma.

Double Eccentric Butterfly Valve: Metal-sealed; handles 425°C steam.

Triple Eccentric Butterfly Valve: Zero-leakage; withstands 700°C/25MPa.

By Connection Type

Wafer Butterfly Valve: Compact, cost-effective.

Lug Butterfly Valve: Mid-line serviceability.

Flanged Butterfly Valve: High-pressure stability.

By Material

Stainless Steel Butterfly Valve: Corrosion-resistant for chemicals.

Carbon Steel Butterfly Valve: Valve body made by Carbon Steel, Valve Disc can be WCB, CF8, CF8M, CF3, CF3M.

Iron Butterfly Valve: Valve body is Ductile Iron or Cast Iron, Valve Disc will be Ductile Iron+Ni, CF8, CF8M, CF3, CF3M.

High Performance Butterfly Valve: Valve seat is RPTFE/PTFE, and The valve seat is installed on the valve plate and can be removed and replaced on the pipeline, it always in Double Eccentric or Triple eccentric design.

Butterfly Valves vs. Ball Valves vs. Gate Valves

| Feature | Butterfly Valve | Ball Valve | Gate Valve |

|---|---|---|---|

| Sealing | Medium-High* | Excellent | Excellent |

| Flow Loss | Medium | Low | Very Low |

| Speed | Fast (90° rotation) | Fast | Slow |

| Best For | Large-diameter lines | High-pressure | Full-bore flow |

| Cost | $ | $$$ | $$ |

| *Depends on seal type (soft/metal) |

Selecting the Right Butterfly Valve

• Corrosive Media: PTFE-lined stainless steel butterfly valve.

• High-Temp/Pressure: Triple-eccentric, metal-seated API 609 butterfly valve.

• Sanitary Use: Polished wafer butterfly valve with EPDM seals.

• Automation: Electric/pneumatic actuators.

Industry Applications

• Oil/Gas: API 609 butterfly valves in refinery pipelines.

• Power Plants: High-performance valves for steam control.

• Water Treatment: Wafer butterfly valves in pumping stations.

• Mining: Wear-resistant designs for slurry transport.

Why Choose API 609-Compliant Valves?

API 609 certification guarantees:

✔️ Leak-free operation under pressure

✔️ Extended service life

✔️ Compliance with global safety norms

✔️ Interchangeability across systems

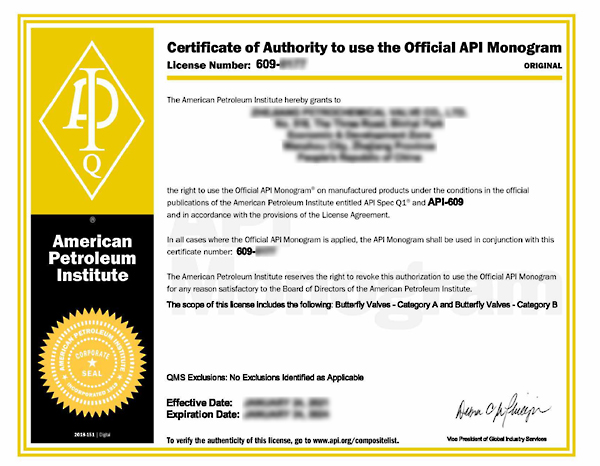

API 609 Certificate Sample:

To verify the authenticity of API license, go to the www.api.org/compositelist

Post time: Jul-14-2025